X. Additional Requirements to cylinders

10.1. General requirements

10.1.1. Cylinders must be calculated and manufactured according to the RD, agreed upon in the prescribed manner.

10.1.2. Cylinders must have valves tightly screwed into the neck holes or into the flow-fill fittings for special cylinders that do not have a neck.

10.1.3. Cylinders for compressed, liquefied and dissolved gases with a capacity of more than 100 liters must be provided with a passport in the form.

10.1.4. Safety valves must be installed on cylinders with a capacity of more than 100 liters. When installing cylinders in a group, it is allowed to install a safety valve on the entire group of cylinders.

10.1.5. Cylinders with a capacity of more than 100 liters, installed as consumable containers for liquefied gases that are used as fuel in cars and other vehicles, in addition to the valve and safety valve, must have a maximum filling level indicator. On such cylinders it is also possible to install a special filling valve, a valve for sampling gas in a vapor state, an indicator of the level of liquefied gas in the cylinder and a drain plug.

10.1.6. The side fittings of valves for cylinders filled with hydrogen and other flammable gases must have a left-hand thread, and for cylinders filled with oxygen and other non-flammable gases - a right-hand thread.

10.1.7. Each valve of cylinders for explosive flammable substances, harmful substances of hazard classes 1 and 2 according to GOST 12.1.007-76 must be equipped with a plug that screws onto the side fitting.

10.1.8. Valves in oxygen cylinders must be screwed in using sealing materials that cannot ignite in an oxygen environment.

10.1.9. The following information must be stamped and clearly visible on the top spherical part of each cylinder:

- manufacturer's trademark;

- cylinder number;

- actual weight of an empty cylinder (kg): for cylinders with a capacity of up to 12 liters inclusive - with an accuracy of 0.1 kg; over 12 to 55 liters inclusive - with an accuracy of 0.2 kg; the weight of cylinders with a capacity of over 55 liters is indicated in accordance with GOST or TU for their manufacture;

- date (month, year) of manufacture and year of the next survey;

- working pressure P, MPa (kgf/cm2);

- test hydraulic pressure Ppr, MPa (kgf/cm2);

- cylinder capacity, l: for cylinders with a capacity of up to 12 l inclusive - nominal; for cylinders with a capacity of over 12 to 55 liters inclusive - actual with an accuracy of 0.3 liters; for cylinders with a capacity of over 55 liters - in accordance with the RD for their manufacture;

- manufacturer's quality control mark, round, 10 mm in diameter (except for standard cylinders with a capacity of over 55 liters);

- standard number for cylinders with a capacity of over 55 liters.

The height of the signs on cylinders must be at least 6 mm, and on cylinders with a capacity of over 55 liters - at least 8 mm.

The weight of cylinders, with the exception of acetylene cylinders, is indicated taking into account the weight of the applied paint, the ring for the cap and the shoe, if provided for by the design, but without the weight of the valve and cap.

On cylinders with a capacity of up to 5 liters or with a wall thickness of less than 5 mm, passport data can be stamped on a plate soldered to the cylinder, or applied with enamel or oil paint.

10.1.10. Cylinders for dissolved acetylene must be filled with an appropriate amount of porous mass and solvent. The organization filling the cylinder with the porous mass is responsible for the quality of the porous mass and for the correct filling of the cylinders. The organization that fills the cylinders with solvent is responsible for the quality of the solvent and its correct dosage.

After filling the cylinders with the porous mass and solvent, the mass of the container is knocked out on its neck (the mass of the cylinder without a cap, but with the porous mass and solvent, shoe, ring and valve).

10.1.11. The outer surface of the cylinders must be painted in accordance with table. 17.

Table 17

|

Name of gas |

Coloring of cylinders |

Inscription text |

Lettering color |

Stripe color |

|---|---|---|---|---|

|

Brown |

||||

|

Argon raw |

Argon raw |

|||

|

Argon technical |

Argon technical |

|||

|

Argon pure |

Argon pure |

|||

|

Acetylene |

Acetylene |

|||

|

Oil&Gas |

Oil&Gas |

|||

|

Dark green |

||||

|

Compressed air |

Compressed air |

|||

|

Brown |

||||

|

Nitrous oxide |

Nitrous oxide |

|||

|

Oxygen |

Oxygen |

|||

|

Medical oxygen |

Medical oxygen |

|||

|

Hydrogen sulfide |

Hydrogen sulfide |

|||

|

Sulfur dioxide |

Sulfur dioxide |

|||

|

Carbon dioxide |

Carbon dioxide |

|||

|

Protective |

||||

|

Aluminum |

||||

|

2 red |

||||

|

Protective |

||||

|

Cyclopropane |

Orange |

Cyclopropane |

||

|

Purple |

||||

|

All other flammable gases |

Name of gas |

|||

|

All other non-flammable gases |

Name of gas |

Painting of cylinders and inscriptions on them can be done with oil, enamel or nitro paints.

Painting of newly manufactured cylinders and application of inscriptions are carried out by manufacturers, and during operation - by filling stations or testing points.

Painting color and text of inscriptions for cylinders used in special installations or intended for filling with gases special purpose, must be agreed upon in the prescribed manner.

10.1.12. The inscriptions on the cylinders are applied along the circumference to a length of at least 1/3 of the circumference, and the stripes are applied along the entire circumference, and the height of the letters on cylinders with a capacity of more than 12 liters must be 60 mm and the width of the strip 25 mm. The sizes of inscriptions and stripes on cylinders with a capacity of up to 12 liters should be determined depending on the size of the lateral surface of the cylinders.

10.2. Inspection of cylinders

10.2.1. Inspection of cylinders can be carried out by filling stations and testing points if they have:

- production premises, as well as technical means that ensure the possibility of high-quality inspection;

- an order on the appointment in the organization of persons responsible for conducting the examination from among specialists with appropriate training;

- instructions for conducting technical inspection of cylinders.

When issuing a permit for inspection, supervisory authorities must register a mark with the appropriate code assigned to this organization (filling station).

10.2.2. Manufacturing quality checks, inspection and acceptance of manufactured cylinders are carried out by department employees technical control manufacturer in accordance with the requirements of the RD for cylinders.

The value of the test pressure and the holding time of the cylinders under the test pressure are set by the manufacturer for standard cylinders according to state standards, for non-standard ones - according to technical conditions, and the test pressure must be no less than one and a half working pressure.

10.2.3. The test pressure for cylinders made of a material whose tensile strength to yield strength ratio is more than 2 can be reduced to 1.25 working pressure.

10.2.4. Cylinders in the manufacturing organization, with the exception of acetylene cylinders, after a hydraulic test must also be subjected to a pneumatic pressure test equal to the operating pressure.

During pneumatic testing, the cylinders must be immersed in a bath of water. Acetylene cylinders must be subjected to pneumatic testing in organizations that fill cylinders with porous mass. Seamless cylinders with two open necks are not subjected to leak testing at the manufacturer, except for cylinders intended to work with media of hazard classes 1, 2, 3, 4 according to GOST 12.1.007-76.

10.2.5. Cylinders of new design or cylinders made from materials not previously used must be tested according to special program, which provides, in particular, for bringing the cylinders to destruction, with a safety margin of minimum value The tensile strength of the metal at 20 °C must be at least 2.4, recalculated for the smallest wall thickness without any increase for corrosion.

10.2.6. The results of the inspection of manufactured cylinders are entered by the manufacturer's quality control department into a statement, which must reflect the following data:

- cylinder number;

- date (month and year) of manufacture (test) of the cylinder and the next inspection;

- cylinder weight, kg;

- cylinder capacity, l;

- working pressure, MPa (kgf/cm2);

- test pressure, MPa (kgf/cm2);

- signature of the manufacturer's Quality Control Department representative.

All completed statements must be numbered, laced and stored in the organization’s QCD files.

10.2.7. Inspection of cylinders, with the exception of acetylene cylinders, includes:

- inspection of the internal, with the exception of cylinders for liquefied hydrocarbon gas (propane-butane) with a capacity of up to 55 liters, and the external surface of the cylinders;

- checking weight and capacity;

- hydraulic test.

The weight and capacity of seamless cylinders up to 12 liters inclusive and over 55 liters, as well as welded cylinders, regardless of capacity, are not checked.

10.2.8. If the results are satisfactory, the organization in which the inspection was carried out stamps on the cylinder its round stamp with a diameter of 12 mm, the date of the performed and the next survey (on the same line with the stamp). The mark must have a code assigned by the State Mining and Technical Supervision Authority of Russia to the organization carrying out the inspection of cylinders.

The results of technical inspection of cylinders with a capacity of more than 100 liters are entered in the cylinder passport. In this case, stamps on the cylinders are not placed.

10.2.9. The results of the inspection of cylinders, with the exception of acetylene cylinders, are recorded by the person who examined the cylinders in a test log, which has, in particular, the following columns:

1. Manufacturer's trademark.

2. Cylinder number.

4. Date of the completed and next survey.

5. Mass stamped on the cylinder, kg.

6. Cylinder weight determined during inspection, kg.

7. Cylinder capacity, stamped on the cylinder, l.

8. Cylinder capacity determined during inspection, l.

9. Working pressure P, MPa (kgf/cm2).

10. Mark on the suitability of the cylinder.

11. Signature of the person who examined the cylinder.

10.2.10. Inspection of acetylene cylinders must be carried out at acetylene filling stations at least every 5 years and consists of:

- inspection of the external surface;

- checking the porous mass;

- pneumatic test.

10.2.11. The condition of the porous mass in acetylene cylinders must be checked at filling stations at least every 24 months.

If the condition of the porous mass is satisfactory, the following should be stamped on each cylinder:

- year and month of testing the porous mass;

- filling station stamp;

- a stamp with a diameter of 12 mm with the image of the letters “Pm”, certifying the verification of the porous mass.

10.2.12. During inspection, acetylene cylinders filled with a porous mass are tested with nitrogen under a pressure of 3.5 MPa (35 kgf/cm2).

The purity of nitrogen used for testing cylinders must be at least 97% by volume.

10.2.13. The results of the inspection of acetylene cylinders are recorded in a test log, which has, in particular, the following columns:

1. Cylinder number.

2. Manufacturer's trademark,

3. Date (month, year) of manufacture of the cylinder.

4. Signature of the person who examined the cylinder.

5. Date of the performed and next inspection of the cylinder.

10.2.14. Inspection of the cylinders is carried out in order to detect corrosion, cracks, caps, dents and other damage on their walls (to determine the suitability of the cylinders for further use). Before inspection, cylinders must be thoroughly cleaned and rinsed with water, and, if necessary, rinsed with an appropriate solvent or degassed.

10.2.15. Cylinders in which, upon examination of the outer and inner surfaces, cracks, membranes, dents, dents, cavities and scratches with a depth of more than 10% of the nominal wall thickness, tears and gouges, wear of the neck thread and some passport data are missing must be rejected.

A loose ring on the neck of the cylinder cannot cause the latter to be rejected. In this case, the cylinder may be allowed for further inspection after securing the ring or replacing it with a new one.

Cylinders with a slanted or weak shoe attachment are not allowed for further inspection until the shoe is reattached.

10.2.16. The capacity of the cylinder is determined by the difference between the weight of the cylinder filled with water and the weight of the empty cylinder or using measuring cups.

10.2.17. Rejection of cylinders based on the results of external and internal inspection must be carried out in accordance with the RD for their manufacture.

It is prohibited to use cylinders on which not all the data provided for in clause 10.1.9 of the Rules are stamped.

Securing or replacing a loose ring on the neck or shoe must be done before the cylinder is inspected.

10.2.18. Seamless standard cylinders with a capacity from 12 to 55 liters are rejected and taken out of service when their weight decreases by 7.5% or more, as well as when their capacity increases by more than 1%.

10.2.19. Cylinders converted to reduced pressure can be used for filling with gases whose operating pressure does not exceed the permissible value for these cylinders, and the following must be stamped on them: mass; working pressure P, MPa (kgf/cm2); test pressure Ppr, MPa (kgf/cm2); date of the conducted and next examination and the stamp of the testing point.

Previously printed information on the cylinder, with the exception of the cylinder number, manufacturer's trademark and date of manufacture, must be filled in.

10.2.20. Rejected cylinders, regardless of their purpose, must be rendered unusable (by notching the neck threads or drilling holes in the body), excluding the possibility of their further use.

10.2.21. Inspection of cylinders must be carried out in separate, specially equipped rooms. The air temperature in these rooms must be at least 12 °C.

For internal inspection of cylinders, it is allowed to use electric lighting with a voltage not exceeding 12 V.

When inspecting cylinders filled with explosive gases, the fittings of the hand lamp and its plug connection must be explosion-proof.

10.2.22. Gas-filled cylinders that are in long-term storage, when the next periodic inspection deadlines arrive, are subject to a random inspection by a representative of the organization’s administration in an amount of at least 5 pieces. from a batch of up to 100 cylinders, 10 pcs. - from a batch of up to 500 cylinders and 20 pcs. - from a batch of over 500 cylinders.

If the inspection results are satisfactory, the storage period for the cylinders is set by the person who carried out the inspection, but not more than 2 years. The results of the sample survey are documented in the appropriate act.

If the inspection results are unsatisfactory, the cylinders are re-examined in the same quantity.

In case of unsatisfactory results during re-examination, further storage of the entire batch of cylinders is not allowed; gas from the cylinders must be removed within the period specified by the person (administration representative) who performed the inspection, after which the cylinders must be subjected to technical inspection each individually.

10.3. Operation of cylinders

10.3.1. The operation, storage and transportation of cylinders must be carried out in accordance with the requirements of the instructions approved in the prescribed manner.

10.3.2. Workers servicing cylinders must be trained and instructed in accordance with clause 7.2.2. Rules

10.3.3. Gas cylinders can be stored both in special rooms and in the open air; in the latter case, they must be protected from precipitation and sunlight.

Storage of oxygen and flammable gas cylinders in the same room is prohibited.

10.3.4. Gas cylinders installed indoors must be located at a distance of at least 1 m from heating radiators and other heating appliances and stoves and at least 5 m from heat sources with open fire.

10.3.5. When using cylinders, the gas contained in them must not be completely consumed. The residual gas pressure in the cylinder must be at least 0.05 MPa (0.5 kgf/cm2).

10.3.6. The release of gases from cylinders into containers with lower operating pressure must be done through a reducer designed for this gas and painted in the appropriate color.

The low pressure chamber of the reducer must have a pressure gauge and a spring safety valve adjusted to the appropriate permitted pressure in the container into which the gas is transferred.

10.3.7. If it is impossible to release gas from the cylinders at the point of consumption due to a malfunction of the valves, the latter must be returned to the filling station. The release of gas from such cylinders at the filling station must be carried out in accordance with instructions approved in the prescribed manner.

10.3.8. Filling stations that fill cylinders with compressed, liquefied and soluble gases are required to keep a cylinder filling log, which, in particular, must indicate:

- filling date;

- cylinder number;

- date of examination;

- mass of gas (liquefied) in the cylinder, kg;

- signature of the person who filled the cylinder.

If at one of the stations cylinders are filled with various gases, then for each gas there must be separate magazine filling.

10.3.9. Filling cylinders with gases must be carried out according to instructions developed and approved by the organization in the prescribed manner, taking into account the properties of the gas, local conditions and requirements standard instructions for filling gas cylinders.

Filling cylinders with liquefied gases must comply with the standards specified in table. 18.

Table 18

|

Name of gas |

Mass of gas per 1 liter of cylinder capacity, kg, no more |

Cylinder capacity per 1 kg of gas, l, not less |

|---|---|---|

Filling of cylinders in which there is no excess gas pressure is carried out after their preliminary check in accordance with the instructions of the organization carrying out the filling (filling station). 10.3.12. Re-attachment of shoes and rings for caps, replacement of valves must be carried out at cylinder inspection points. After repairs involving its disassembly, the valve must be checked for tightness at operating pressure. 10.3.13. It is allowed to attach shoes to cylinders only after releasing the gas, unscrewing the valves and appropriate degassing of the cylinders. Cleaning and painting gas-filled cylinders, as well as strengthening the rings on their necks, is prohibited. 10.3.14. Cylinders containing poisonous gases must be stored in special enclosed areas, the arrangement of which is regulated by the relevant rules and regulations. 10.3.15. Filled cylinders with shoes attached to them must be stored in an upright position. To protect against falling, cylinders must be installed in specially equipped nests, cages or protected by a barrier. 10.3.16. Cylinders that do not have shoes can be stored horizontally on wooden frames or racks. When storing in open areas, it is allowed to stack cylinders with shoes in stacks with rope spacers, wooden beams or rubber between horizontal rows. When stacking cylinders in stacks, the height of the latter should not exceed 1.5 m. The valves of the cylinders should face the same direction. 10.3.17. Warehouses for storing cylinders filled with gases should be one-story with light-type coverings and not have attics. Walls, partitions, and coverings of warehouses for storing gases must be made of fireproof materials of at least II degree of fire resistance; Windows and doors must open outwards. Window and door glass should be frosted or painted over with white paint. The height of storage areas for cylinders must be at least 3.25 m from the floor to the lower protruding parts of the roofing. The floors of warehouses must be level with a non-slip surface, and warehouses for cylinders with flammable gases must have a surface made of materials that prevent sparking when hitting them with any objects. 10.3.18. The equipment of warehouses for flammable gas cylinders must comply with the standards for explosion-hazardous premises. 10.3.19. Instructions, rules and posters for handling cylinders located in the warehouse must be posted in warehouses. 10.3.20. Warehouses for gas cylinders must have natural or artificial ventilation in accordance with the requirements of sanitary design standards. 10.3.21. Warehouses for cylinders with explosive and fire hazardous gases must be located in the lightning protection zone. 10.3.22. The warehouse for storing cylinders must be divided by fireproof walls into compartments, in each of which no more than 500 cylinders (40 l) with flammable or poisonous gases and no more than 1000 cylinders (40 l) with non-flammable and non-toxic gases are allowed. Compartments for storing cylinders with non-flammable and non-toxic gases can be separated by fireproof partitions at least 2.5 m high with open openings for the passage of people and openings for mechanical equipment. Each compartment must have its own exit to the outside. 10.3.23. Gaps between warehouses for cylinders filled with gases, between warehouses and adjacent industrial buildings, public premises, and residential buildings must meet the requirements of the ND. 10.3.24. The movement of cylinders at gas filling and consumption points must be carried out on specially adapted carts or using other devices. 10.3.25. Transportation of cylinders filled with gases must be carried out on spring transport or on trucks in a horizontal position, always with gaskets between the cylinders. Wooden blocks with cut-out sockets for cylinders, as well as rope or rubber rings with a thickness of at least 25 mm (two rings per cylinder) or other gaskets that protect the cylinders from hitting each other can be used as gaskets. All cylinders during transportation must be stacked with valves in one direction. It is allowed to transport cylinders in special containers, as well as without containers in a vertical position, always with gaskets between them and protection from possible falling. 10.3.26. Transportation and storage of cylinders must be done with the caps screwed on. Transportation of cylinders for hydrocarbon gases is carried out in accordance with safety rules in the gas industry, approved by the State Technical Supervision Authority of Russia. Storing filled cylinders before distributing them to consumers is permitted without safety caps. 10.3.27. Transportation of cylinders by road, rail, water and air transport must be carried out in accordance with the rules of the relevant ministries and departments. 10.3.28. Monitoring compliance with the Rules in filling organizations, filling stations and testing points must be carried out by an inspector from the Gosgortekhnadzor of Russia. |

Oxygen

The parameters and dimensions of oxygen cylinders can be viewed according to GOST 949-73 “Small and medium steel cylinders for gases at Рр ≤ 19.7 MPa”. The most popular are cylinders with volumes of 5, 10 and 40 liters.

According to GOST 5583-78 “Gaseous technical and medical oxygen” (Appendix 2), the volume of gaseous oxygen in a cylinder (V) in cubic meters under normal conditions is calculated by the formula:

Vb — cylinder capacity, dm3;

K1 - coefficient for determining the volume of oxygen in a cylinder under normal conditions, calculated by the formula

K 1 = (0.968P + 1) * *

P - gas pressure in the cylinder, measured by a pressure gauge, kgf/cm2;

0.968 - coefficient for converting technical atmospheres (kgf/cm2) into physical ones;

t - gas temperature in the cylinder, °C;

Z is the oxygen combustion coefficient at temperature t.

The values of coefficient K1 are given in Table 4, GOST 5583-78.

Let's calculate the volume of oxygen in the most common cylinder in construction: a volume of 40 liters with a working pressure of 14.7 MPa (150 kgf/cm2). Coefficient K1 is determined according to Table 4, GOST 5583-78 at a temperature of 15°C:

V = 0.159 40 = 6.36m3

Conclusion (for the case under consideration): 1 cylinder = 40l = 6.36m3

Propane-butane

The parameters and dimensions of oxygen cylinders for propane, butane and their mixtures can be viewed according to GOST 15860-84. Currently, four types of these products are used, with volumes of 5, 12, 27 and 50 liters.

Under normal atmospheric conditions and a temperature of 15°C, the density of propane in the liquid state is 510 kg/m3, and butane 580 kg/m3. Propane in the gas state at atmospheric pressure and temperature 15°C is 1.9 kg/m3, and butane is 2.55 kg/m3. Under normal atmospheric conditions and a temperature of 15°C, 0.392 m3 of gas is formed from 1 kg of liquid butane, and 0.526 m3 from 1 kg of propane.

Let's calculate the weight of the propane-butane mixture in the most common cylinder in construction: volume 50 with a maximum gas pressure of 1.6 MPa. The proportion of propane according to GOST 15860-84 must be at least 60% (note 1 to Table 2):

50l = 50dm3 = 0.05m3;

0.05 m3 (510 0.6 + 580 0.4) = 26.9 kg

But due to the gas pressure limitation of 1.6 MPa on the walls, more than 21 kg cannot be filled into a cylinder of this type.

Let's calculate the volume of the propane-butane mixture in the gaseous state:

21kg (0.526 0.6 + 0.392 0.4) = 9.93 m3

Conclusion (for the case under consideration): 1 cylinder = 50l = 21kg = 9.93m3

Acetylene

The parameters and dimensions of acetylene cylinders can be viewed according to GOST 949-73 “Small and medium steel cylinders for gases at Рр ≤ 19.7 MPa”. The most popular are cylinders with volumes of 5, 10 and 40 liters. The body of an acetylene cylinder differs from the body of an oxygen cylinder in its smaller size.

At a pressure of 1.0 MPa and a temperature of 20 °C, a 40-liter cylinder holds 5 - 5.8 kg of acetylene by mass (4.6 - 5.3 m3 of gas at a temperature of 20 °C and 760 mmHg).

The approximate amount of acetylene in the cylinder (determined by weighing) can be determined by the formula:

Va = 0.07 E (P – 0.1)

0.07 – coefficient, which takes into account the amount of acetone in the cylinder and the solubility of acetylene.

E – water volume of the cylinder in cubic dm;

P – pressure in the cylinder, MPa (pressure 1.9 MPa (19.0 kgf/cm2) at 20 °C according to GOST 5457-75 “Dissolved and gaseous technical acetylene”);

0.1 – atmospheric pressure in MPa;

Weight of 1 m3 of acetylene at a temperature of 0°C and 760 mmHg. is 1.17 kg.

Weight of 1 cubic meter of acetylene at a temperature of 20°C and 760 mm Hg. is 1.09 kg.

Let's calculate the volume of acetylene in a 40 liter cylinder with a working pressure of 1.9 MPa (19 kgf/cm2) at a temperature of 20°C:

Va = 0.07 40 (1.9 – 0.1) = 5.04 m3

Weight of acetylene in a 40 liter cylinder with a working pressure of 1.9 MPa (19 kgf/cm2) at a temperature of 20°C:

5.04 1.09 = 5.5kg

Conclusion (for the case under consideration): 1 cylinder = 40l = 5.5kg = 5.04m3

Carbon dioxide (carbon dioxide)

Carbon dioxide (according to GOST 8050-85 “Gaseous and liquid carbon dioxide”) is used as a shielding gas for electric welding work. Mixture composition: CO2; Ar + CO2 ; Ar + CO2 + O2. Manufacturers can also label it as a mixture of MIX1 - MIX5.

The parameters and dimensions of acetylene cylinders can be viewed according to GOST 949-73 “Small and medium steel cylinders for gases at Рр ≤ 19.7 MPa”. The most popular are cylinders with volumes of 5, 10 and 40 liters.

At a working pressure of carbon dioxide in the cylinder of 14.7 MPa (150 kgf/cm2), filling factor: 0.60 kg/l; at 9.8 MPa (100 kgf/cm2) – 0.29 kg/l; at 12.25 MPa (125 kgf/cm2) – 0.47 kg/l.

The volumetric weight of carbon dioxide in the gaseous state is 1.98 kg/m³, under normal conditions.

Let's calculate the weight of carbon dioxide in the most common cylinder in construction: a volume of 40 liters with a working pressure of 14.7 MPa (150 kgf/cm2).

40l 0.6 = 24kg

Let's calculate the volume of carbon dioxide in the gaseous state:

24kg / 1.98 kg/m3 = 12.12m3

Conclusion (for the case under consideration): 1 cylinder = 40l = 24kg = 12.12m3

The inert properties of nitrogen have allowed it to be widely used in industry and national economy. It can be transported in cryogenic containers, Dewar flasks or cylinders. Large containers allow liquid nitrogen to be transported, but require the use of special tanks, which increases transport costs. If a relatively small volume of nitrogen is needed, then it is more profitable to use cylinders. It is allowed to transport up to 24 40 liter vessels filled with nitrogen in one vehicle. This ensures their reliable fixation, eliminating the possibility of impacts and depressurization.

Types and markings of cylinders

According to the rules, a certified nitrogen cylinder is painted black, with a yellow inscription “Nitrogen” and a brown stripe under it. Vessels for storing nitrogen under pressure are produced with a volume of 5 to 50 liters. The containers have a valve, a shoe and a cap. The serial number, actual weight and capacity of the container, operating and test pressure, and date of manufacture are stamped on the vessel body near the neck. In the future, information about recertification will be entered there.

Scope of application of liquefied nitrogen and rules for using cylinders

Nitrogen gas is a good refrigerant and prevents oxidation and decay processes. In addition, it is explosion-proof, fireproof and not harmful to humans. All these properties have made it possible to use it in many production processes.

Nitrogen is used for:

- purging of tanks and pipelines in the petrochemical industry;

- fire extinguishing systems;

- displacing oxygen from non-oxidation areas in electronics manufacturing;

- creating pressure or low temperature in food production;

- freezing in cryogenic medicine;

- airbags and tire inflation in the automotive industry;

- other processes.

Keep nitrogen cylinders necessary in a specially equipped place to prevent them from falling, heating, or damage. In this case, the caps must be screwed on to protect the valve from damage and prevent oil and moisture from entering the cylinder.

Containers with an unexpired certification period that are clean, without dents or other damage to the body are supplied for filling. To prevent contamination of the cylinder with air or other gases, it is necessary to ensure a residual pressure in the container of about 1.5 atm. Do not use nitrogen cylinders to fill with other gases. To monitor the conditions of storage, use and transportation of nitrogen cylinders, a responsible person is appointed at the enterprise. This is secured by an order or directive from the manager.

Offer agreement

This Agreement in accordance with Article 437 of the Civil Code Russian Federation is a public offer (offer of the seller AlfaTorgService LLC) for the sale to individuals and legal entities(buyers) of goods remotely through the online store on the website http://site ,

According to clause 3 of Article 438 of the Civil Code of the Russian Federation, the person who ordered the goods presented on the website from the seller AlfaTorgService LLC . , is considered to have accepted the terms of this offer and to have concluded this Agreement with the seller on the terms set out therein (having accepted this offer of the seller).

The buyer has the right to accept the terms of this Offer Agreement (and order goods from the seller) at any time convenient for the buyer.

Dear buyer!

If you do not agree with the text of this Public Offer Agreement or its individual clauses, the seller invites you to refuse to purchase the Products from the seller. If you place an order for goods from the seller, you unconditionally accept all the terms of this Agreement and undertake to fully comply with the terms of cooperation offered by the seller.

Limited Liability Company "AlfaTorgService" TIN 7807377858

checkpoint 780701001 OGRN 1137847056764 OKPO 50062087 OKATO 40279562000

Bank: North-West Bank OJSC Sberbank of Russia BIC 044030653

Cash account 30101810500000000653 Cash account 40702810155240001949

1), hereinafter referred to as the “Seller”, represented by General Director Apakina E.V., acting on the basis of the Charter, on the one hand, and Buyer, ordered from Seller's Products, presented on the website http://site, on the other hand, and collectively referred to as the “Parties”, have entered into this Offer Agreement as follows:

1. Subject of this Agreement:

1.1. The Seller undertakes to transfer into ownership of the Buyer through distance selling the Products presented on the website http://site . and ordered by the Buyer, and the Buyer undertakes to accept and pay for the Goods ordered by him in the manner and on the terms in accordance with this Agreement.

1.2. In the event that this Agreement does not regulate certain terms of cooperation between the Parties when purchasing and selling Goods, the Parties are guided by the current legislation of the Russian Federation.

1.3. The Seller reserves the right to change this Agreement.

1.4. The address of the current version of this Agreement is located on the Internet at the address: http://site/

1.5. Information posted on the Site is publicly available, unless otherwise provided by this Agreement.

2. Concepts and terms used in this Agreement and in the cooperation of the Parties:

Website- An Internet site owned by the Seller, located on the Internet at http://site/, where the Products offered by the Seller for purchase are presented, as well as the terms of payment and delivery of the Products to Buyers. The site is the Seller's online store.

Product- genuine goods - from the assortment presented for sale on the Seller’s Website.

Buyer- a registered User who has placed an Order on the website http://site/ for the purchase of Products listed on the Website and available from the Seller.

Order- a duly completed request from the Buyer for the purchase of Goods selected on the Site and available from the Seller, as well as for their delivery to the address specified by the Buyer under the conditions specified on the Site in the “Delivery and Payment” section.

3. Conditions for placing an Order and selling Products

3.1. Ordering Goods from the Buyer is possible by using the Site service after registering the Buyer on the Site, or by telephone (without mandatory registration).

3.2. By ordering Products in any way, the Buyer agrees to the terms of placing an Order and selling Products established by the Seller. The User agrees to the terms of placing an Order and selling Products by checking the box “I agree with these conditions” when registering on the Site and placing an Order.

3.3. All information materials, presented on the Site in relation to the Products, are for reference only and cannot fully convey reliable information about the properties and characteristics of the Product, including size, color, shape. If the Buyer has questions regarding the properties and characteristics of the Product, the Buyer is obliged to contact the Seller for additional clarification before placing an Order. Placing an Order by the Buyer means sufficient and complete familiarization of the Buyer with the Product.

3.4. To place an Order through the Site, the Buyer must mark the Product being ordered and its quantity, and then consistently follow the prompts of the Site service to place the Order. When ordering for the first time through the Site, the Buyer goes through the registration procedure on the Site. Further orders through the site are made using the Buyer’s registered login.

To place an Order by telephone, the Buyer is obliged to use the telephone number of the Seller’s contact center listed on the Site and verbally inform the operator accepting the Order, the name and/or article number of the ordered Product and its quantity, as well as the necessary contact information.

The Buyer bears full responsibility for providing incorrect information when placing an Order, which results in the Seller being unable to properly fulfill its obligations to the Buyer.

3.5. By providing his personal data when ordering Goods, the Buyer agrees to their processing by the Seller, including for the purpose of promoting the Products and services by the Seller.

3.6. The Buyer’s personal data is processed in accordance with the Federal Law “On Personal Data” No. 152-FZ. The Seller is not responsible for the actions of third parties who have used the User’s personal data, while taking all available and legal measures and methods to protect information about the User registered on the Site.

3.7. The seller has the right to send informational messages, including advertising messages, by email and mobile phone Buyer. The User has the right to refuse to receive advertising and other information without explaining the reasons for the refusal, by notifying the Buyer about this in any convenient way. Service messages informing the Buyer about the Order and the stages of its processing are sent by the Seller automatically and cannot be rejected by the User.

3.8. The Seller is not responsible for the actions of third parties who used the User’s personal data.

3.9. After placing an Order, the Buyer is provided with information about the expected delivery date by sending an email to the address specified by the Buyer during registration, or by telephone. The Seller's representative servicing this Order clarifies the details of the Order, agrees on the delivery date, which depends on the availability of the Goods ordered by the Buyer in the Seller's warehouse and the time required for processing and delivery of the Order.

3.10. It is not possible to order Products marked “Out of Stock” through the Website services or by telephone.

3.11. If the Buyer orders a Product that does not have the “Out of Stock” mark, but at the time of execution of this Order by the Buyer the Product is already out of stock at the Seller’s warehouse, the Seller has the right to exclude the specified Product from the Order and/or cancel the Buyer’s Order by notifying the Buyer about this by sending a corresponding email message to the address specified by the Buyer during registration, or a call from the Seller’s representative.

3.12. In case of cancellation of a fully or partially prepaid Order, the cost of the canceled Product is returned by the Seller to the Buyer in the manner in which the Product was paid for.

3.13. The Seller takes all possible legal measures to ensure that all Products presented on the Site are available in its warehouse.

3.14. The Seller has the right to cancel the Buyer's Orders, which include Products that the Buyer previously refused 2 or more times, indicating reasons not related to the presence of defects in these Products.

3.15. The Seller has the right to refuse to place an Order if the Buyer has already placed and not received other Orders totaling 5,000 (five thousand) rubles or more.

3.16. The Seller has the right to refuse the Buyer to place any subsequent Order and sell the Goods if, in the Seller’s opinion, the Buyer has shown low loyalty to the Seller in the past. Low loyalty by the Seller means incorrect behavior of the Buyer, the presence of claims, legal disputes initiated and/or on behalf of the Buyer, repeated returns of Goods of proper quality to the Seller and other situations.

4. Delivery of the Order:

4.1. Methods of delivery of Goods are indicated on the Site in the “Delivery and Payment” section at http://site/

4.2. Delivery is a separate service of the Seller. Delivery is not an integral part of the Product purchased by the Buyer.

4.3. The delivery area for the Products presented on the Site is limited to the Russian Federation.

Delivery of Orders in Moscow and the Moscow region is carried out by the Seller through its duly authorized representatives directly to the address specified by the Buyer when placing the Order.

Delivery of Orders to other regions is carried out by sending the Goods through post offices and/or delivery services indicated on the website page at http://site/

4.4. When placing an Order, the Buyer chooses the delivery method independently from those proposed by the Seller. The delivery time is agreed upon by the parties when the Seller’s representative calls the Buyer.

4.5. The cost of delivery is calculated individually, based on the cost of the Order, the weight of the Goods, region and delivery method, as well as (if necessary) form of payment, and is indicated on the Site at the last stage of placing the Order.

4.6. Upon delivery, the Order is handed over to the Buyer or a third party specified in the Order as the recipient (hereinafter the Buyer and the third party are referred to as the “Recipient”). If it is impossible to receive an Order paid for in cash by the persons indicated above, the Order may be delivered to a person who can provide information about the Order (shipment number and/or full name of the Recipient), as well as pay the cost of the Order in full to the person delivering the Order.

4.7. In order to avoid cases of fraud, as well as to fulfill the obligations assumed, when delivering a prepaid Order, the person delivering the Order has the right to request an identification document of the Recipient, as well as indicate the type and number of the document provided by the Recipient on the receipt for the Order.

4.8. Ownership of the Goods, as well as the risk of accidental loss or damage to the Goods, passes to the Buyer from the moment:

Transferring the Order to the Buyer or his authorized recipient and affixing signatures by the indicated persons in the documents confirming the delivery of the Order;

Or receipt of the Goods by the Recipient at the post office.

Delivery as separate service of the Seller, ends at the time the Recipient receives the Goods.

4.9. Features of receiving an Order from the Seller’s delivery service at the address specified by the Buyer:

The Buyer or his authorized recipient is obliged to inspect the delivered Goods and check for compliance with the declared quantity, assortment and completeness of the Goods, as well as check the service life of the delivered Goods and the integrity of the packaging. If there are no claims to the delivered Goods, the Recipient signs the “Order Delivery Form” and pays for the Order (if the Order was not paid for in advance, in confirmation of which the Buyer is obliged to provide the Seller’s representative who delivered the Order with a payment document confirming the payment made ).

The buyer or his authorized recipient signs for the delivery documents.

The signature in the specified delivery documents indicates that the Recipient has not made any claims to the Goods and the Seller has fully and properly fulfilled its obligation to transfer the Goods.

The courier's time at the Recipient's address should be no more than 10 minutes.

4.10. Features of receiving an Order at post offices:

Upon receipt of the Order at the post office, the Recipient, after paying for the delivered Goods, is obliged to inspect the delivered Goods and open them in the presence of Russian Post employees to check the Goods for compliance with the declared quantity, assortment and completeness of the Goods, as well as check the service life of the delivered Goods and the integrity of the packaging.

If there are claims against the delivered Goods (non-delivery, inclusion of Goods different from those specified in the shipment inventory, manufacturing defects, other claims), at the direction of the Recipient, Russian Post employees draw up a Report on identified discrepancies.

If the Recipient has not made claims in the above manner, then the Seller is considered to have fully and properly fulfilled its obligation to transfer the Goods.

In the event of a return of a Product delivered via Russian Post due to claims against the Product, the Recipient is obliged to attach the following documents to the Shipment containing the returned Product:

Return Application cash;

- a copy of the report on identified inconsistencies;

- a copy of the payment receipt;

- a copy of the shipment inventory.

4.11. Claims to the quality of the purchased Goods that arise after receipt and payment of the Goods are considered in accordance with the Law of the Russian Federation “On the Protection of Consumer Rights” and the Seller’s warranty obligations. In this regard, the purchase of Goods with delivery does not give the Buyer the right to demand delivery of the purchased Goods for the purposes of warranty service or replacement, and does not provide the opportunity to carry out warranty service or replacement of the Goods by visiting the Buyer and does not imply the possibility of returning the cost of delivery of the Goods in cases where the Buyer has the right to a refund for the Goods as such, in accordance with the Law of the Russian Federation “On the Protection of Consumer Rights”.

4.12. Delivery delays are possible due to unforeseen circumstances that are not the fault of the Seller.

4.13. In case of non-delivery of the Order, the Seller shall reimburse the Buyer for the cost of the Order prepaid by the Buyer and delivery in full after receiving confirmation of the loss of the Goods under the relevant Buyer’s Order from the Seller’s representative.

5. Price of the Product and terms of payment for the Order:

5.1. All payments between the Parties are made in rubles.

5.2. The price of the Product is indicated on the Site.

5.3. The price of the Product presented on the Site may be changed by the Seller unilaterally. In this case, the price of the Product ordered by the Buyer is not subject to change.

5.4. The Seller may set a discount for individual (or all) items of the Product (a promotion valid at the time the Buyer Orders these items of the Product). The discounted price of the Product is indicated on the website or calculated when placing an order.

5.5. The Buyer pays for the Order by choosing, at his own discretion and capabilities, one of the methods indicated on the Site.

6. Exchange and return of Goods:

6.1. The return of the Goods is carried out in accordance with the requirements and provisions established by the Law of the Russian Federation dated February 17, 1992. No. 2300-1 “On the protection of consumer rights” (if the Buyer of the Goods from the Seller is individual), Decree of the Government of the Russian Federation of January 19, 1998 N55 with appropriate amendments, as well as other applicable legislation of the Russian Federation.

6.2. The Buyer has the right to refuse the ordered Product at any time before receiving it.

6.3. The Buyer can return Goods of good quality within 7 (Seven) calendar days from the date of receipt of the Goods; return Goods of inadequate quality is carried out during the warranty period, and if the Goods have no warranty period established - within a reasonable time, guided by the provisions of the Law of the Russian Federation “On protection of consumer rights" - provided that the goods have not been used, their presentation is preserved, consumer properties, seals, factory labels, packaging (if packaging is part of the Goods), as well as cash receipt(the absence of a receipt is not a basis for refusing the Buyer to satisfy his demands for the return of the Goods, provided that the Buyer complies with other return conditions).

6.4. To return the Goods of proper quality, the Buyer sends an application with copies of documents confirming the fact of purchase to email Seller . The Seller accepts the application for consideration within 5 working days from the date of its receipt from the Buyer and agrees with the Buyer on the conditions for returning the Goods and funds. The seller has the right to refuse to return the goods if it turns out that the goods have been used and/or have mechanical damage (cracks, scratches, chips).

6.5. When returning a Product of proper quality, the Buyer is obliged to compensate the seller for all costs associated with the delivery of the returned Product.

6.6. The Seller returns the money paid for the goods within 10 calendar days from the date of receipt of the corresponding request from the Buyer.

6.7. A product of inadequate quality means a Product that is defective and cannot ensure the performance of its functional qualities. Differences in design or design elements from those stated in the description on the Site are not a sign of poor quality or non-functionality of the Product.

6.8. The Buyer to whom the Product was sold of inadequate quality (if its defects were not specified by the Seller) has the right, at his own discretion, to demand that the Seller perform one of the following actions:

Replacement of defective Goods with goods of adequate quality;

- proportionate reduction in the purchase price low-quality goods;

- free elimination of defects in the Product (if such defects can be eliminated);

- reimbursement to the Buyer of expenses for eliminating defects in the Product by the Buyer (if such defects can be eliminated).

6.9. If defects are discovered in the Product, the properties of which do not allow them to be eliminated ( food products, goods household chemicals and the like), the Buyer, at his choice, has the right to demand the replacement of such Products with goods of adequate quality or a proportionate reduction in the purchase price of the Products.

6.10. In relation to technically complex, low-quality Goods, the Buyer has the right to demand its replacement or refuse to purchase the Goods and demand a refund of the amount paid for the Goods in the event of a significant violation of the requirements for its quality, in accordance with the requirements of the current legislation of the Russian Federation. The Buyer returns such Goods to the Seller, and the Seller bears the costs of return. K: Civil Code of the Russian Federation: Article 503/(10832) See. List of technically complex goods approved by Decree of the Government of the Russian Federation of November 10, 2011 No. 924

6.11. The replacement of the Goods by the Seller at the request of the Buyer is carried out in cases, on the conditions and within the time limits provided for by the Law “On the Protection of Consumer Rights”.

6.12. Goods established by Decrees of the Government of the Russian Federation dated October 20, 1998 N 1222, dated February 6, 2002 N 81 and other applicable regulations are not subject to exchange.

6.13. If at the time of the Buyer’s request to replace the Product, a similar Product is not available for sale from the Seller, the Buyer has the right to demand a refund of the amount paid for the specified Product.

6.14. Refunds are made by returning the cost of the paid Goods to bank card, by postal order or in cash at the company’s office at the address indicated on the Site in the “Contacts” section. The method of refund must be indicated in the application for the return of the Goods.

7. Responsibility of the Parties.

7.1. The Seller is not responsible for damage caused to the Buyer due to improper use of the Goods purchased from the Buyer.

7.2. The Seller is not responsible for the information provided by the User on the Site in a publicly accessible form.

7.3. Under any circumstances, the total liability of the Seller under this Agreement, for any claim or claim in relation to the Offer agreement or its execution, is limited to the amount of payment paid to the Seller by the Buyer for the relevant Order, but not more than 10,000.00 (Ten thousand) rubles, and is assigned to The seller if there is guilt in his actions.

7.4. The Seller is not responsible for the inability to fulfill the Buyer’s order for any reason beyond its control, including disruption of communication lines, equipment malfunction, failure to fulfill the obligations of suppliers of certain services, etc.

7.5. If for any reason the Seller does not ship the Goods to the Buyer or ships the Goods in violation of the deadlines, the Seller’s liability for the violation is limited solely to the extension of the delivery time for the Goods.

7.6. The Seller under no circumstances bears any responsibility under this Agreement for a) any actions and/or inactions that are a direct or indirect result of the actions/inactions of any third parties; b) any indirect losses and/or lost profits of the Buyer and/or third parties, regardless of whether the Seller could have foreseen the possibility of such losses or not; c) use (impossibility of use) and any consequences of the use (impossibility of use) by the Buyer of the chosen form of payment for the Goods under this Agreement when paying for the Order.

7.7. The parties are released from liability for violation of the terms of this User Agreement if such violation is caused by force majeure circumstances (force majeure), including: actions of authorities state power(including the adoption of legal acts), fire, flood, earthquake, other natural disasters, lack of electricity and/or computer network failures, strikes, civil unrest, riots, any other circumstances, not limited to the above, that may affect fulfillment by the Parties of their obligations.

7.8. The recognition by a court of any provision of this Offer Agreement as invalid or unenforceable does not entail the invalidity or unenforceability of other provisions of this Agreement.

8. Duration of the Agreement:

8.1. This Agreement comes into force from the moment it is signed by the Parties and is valid until the Parties fully fulfill their obligations under the Agreement. The moment of signing on the part of the Buyer is the registration of the Buyer on the Site or placing an order through the Site; The moment of signing by the Seller is recognized as the moment the Seller posts this Agreement on the Site.

9. Final terms:

9.1. All disputes arising between the parties must be resolved through direct negotiations and written correspondence with claims in compliance with the pre-trial procedure for resolving disputes.

9.2. Unsettled disputes are subject to judicial review in accordance with the current legislation of the Russian Federation.

9.3. In all other respects that are not provided for in this Agreement, the Parties are guided by the current legislation of the Russian Federation.

9.4. Legal address and Seller details:

AlfaTorgService LLC

TIN 7807377858 checkpoint 780701001 OGRN 1137847056764

OKPO 50062087 OKATO 40279562000

Legal address: St. Petersburg, Kuznetsova Avenue, 23, building 1, room 311

Bank: North-West Bank OJSC "Sberbank of Russia"

BIC 044030653

C/account 30101810500000000653

Account 40702810155240001949

General Director: Apakina Elena Viktorovna

To store and transport nitrogen, special steel cylinders are used that hold 40 liters, which is equal to six cubic meters of this gas under a pressure of 150 kgf/sq.cm. Nitrogen containers are painted black and the word “Nitrogen” is printed on them with yellow paint.

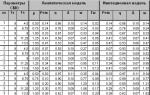

Parameters of cylinders for filling with nitrogen according to GOST 949-73 “Steel cylinders of small and medium volume for gases. Specifications».

Nitrogen is inert, non-toxic and non-hazardous at atmospheric pressure and normal conditions. It is part of the air - the Earth's atmosphere, making up 75.6 percent of the calculated mass. In industry, it is obtained by isolating it from the air by liquefying and separating gases.

Nitrogen is used in:

— As a refrigerant for cooling and deep freezing. Cryopreservation of tissue samples, organs and cells.

— When extinguishing a fire, it displaces oxygen, stopping combustion. Evaporating does not spoil the value.

— Cryogenic cutting.

— Synthesis of dyes. They are used in light industry for dyeing fabrics. Quick-drying nitro enamels and nitro paints are required in repairs and construction. Food colors change the color of the sausages from pale brown to bright pink.

— Production of ammonia, which is a refrigerant in many refrigeration units. Raw materials for the production of soda, polymers, nitric acid. Its 10% solution is called ammonia in medicine.

— Creation of explosives.

— Industrial production nitrogen fertilizers: urea, ammonium nitrate, ammonium sulfate and nitrate.

— For filling tires aircraft;

— As a protective environment that prevents oxidation in contact with oxygen, burning or rotting.

— Cooling of various machinery and equipment.

— Petrochemicals, electronics, mining, chemical and oil and gas industries, metallurgy, pharmaceuticals.

- Medicine. The formula of nitroglycerin, a medicine for heart disease (angina), contains nitrogen atoms. Nitrous oxide is in demand for anesthesia. Nitrogen chloride has a diuretic effect.

— In the form of a special gas environment for storage in food packaging.

- Cryotherapy - cold treatment. Freezing warts with liquid nitrogen.

- Construction. Cooling of concrete and freezing of soil.

With high blood pressure and lack of oxygen, nitrogen can cause intoxication, narcosis and suffocation. Nitrogen, in the event of a rapid decrease in pressure, causes decompression sickness. Maximum care must be taken when transporting and using it. Pressurized cylinders may be explosive. Transportation of liquid and gaseous nitrogen is carried out in accordance with the rules for the transportation of dangerous goods different types transport, cars and rail.

The use of low-quality, insufficiently pure gas and untested, faulty equipment can lead to emergency situation. To avoid negative consequences, you should buy nitrogen only from companies that provide reliable guarantees. The well-equipped DP Air Gas laboratory conducts research to certify the quality of the products sold. A laboratory certificate is issued.

The DP Air Gas company sells gaseous technical nitrogen of the first grade. Volume fraction not less than: 99.6%. Nitrogen of increased purity, second grade, gaseous - 99.95%. With the highest purification - 99.999%, first grade nitrogen of special purity. Technical liquid nitrogen, first grade. The percentage of nitrogen is not less than 99.6. Requirements for the quality of nitrogen are determined by DSTU GOST 9293 - 09 “Nitrogen, gaseous and liquid. Technical conditions". Possible impurities are inert gases: neon, argon, helium and water vapor. The maximum permissible reduction in the mass of liquid nitrogen as a result of its evaporation during transportation or storage is no more than ten percent.

The quality of the nitrogen provided by the company is guaranteed and complies with DSTU GOST 9293-09 “Liquid and gaseous nitrogen”. The cylinders into which the gas is filled also fully meet standard requirements. They undergo timely inspection, repair, cleaning of the internal surface, hydrotesting, painting and application of the necessary inscriptions.

The company offers cylinder rental services: daily, monthly or for an agreed time. Repair or replacement of valves. Inspection of cylinders and filling them with nitrogen. Delivery of gas-filled containers is carried out throughout Ukraine, timely and uninterrupted. Detailed list company products is located .