One of the most profitable directions business is manufacturing disposable tableware. People use plastic dishes when having picnics outside the city, on various trips, at children's parties, so the demand for this product is not decreasing, and this type of product will remain in demand for many years to come. The difference between this type of tableware and porcelain and glass is its light weight, ease of transportation and low price.

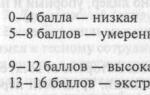

Our business assessment:

Starting investment - 20,000,000 rubles.

Market saturation is high.

The difficulty of starting a business is 8/10.

Reasons for choosing this niche

Many people are mistaken when they claim that production plastic dishes is exclusively seasonal business. In practice, entrepreneurs have proven that this type of business is year-round, the reason for this is that people use utensils intended for one use all the time.

This type of business is highly profitable. The main advantages of plastic utensils include their hygiene and safety. Using this type of plates, containers, glasses and cutlery saves time for putting things in order after various special events.

Business in the production of disposable tableware involves the use of high-tech equipment, which allows you to obtain high quality goods. The production line for disposable tableware, which is located at the enterprise, allows us to produce glasses of various capacities, as well as bowls, different sizes plates, drinking straws, cutlery and other disposable products.

An entrepreneur should understand that there are the following types of clients:

- people buying goods for seasonal picnics, celebrations, events;

- outlet owners catering, lunch delivery services, cafes, as well as owners, drinks and oxygen cocktails.

For second clients it is carried out more often wholesale disposable tableware.

It is noted that disposable plastic tableware is difficult to sell in a “young” business at first, since it is necessary to form a customer base. Only a high quality product can attract potential buyers. It is important to hire an experienced advertising manager who can promote the business and build a customer base.

Important stages of production organization

In order for a business to make a profit, it is necessary to complete several important steps:

- register a business;

- buy equipment;

- find employees.

How to register a business?

To open a plant for the production of disposable tableware in Russia, it is necessary to legally register soybeans entrepreneurial activity by completing the relevant documents. When choosing between an individual entrepreneur and an LLC, you should focus on the expected profit from production. The form of business in the form of an individual entrepreneur is registered if it is intended small production. If an entrepreneur is going to start a large business, then an LLC (limited liability company) is formed. The advantages of the latter include greater trust of partners in the founder of the production, a simplified taxation system, as well as the possibility of receiving significant discounts on raw materials for the production of disposable plastic tableware.

To sell manufactured products, it is mandatory to obtain a certificate that confirms the product’s compliance with established standards according to GOST.

Where should the production be located?

The workshop should be located outside the city. The mini plant has an area of about 100 m². Of these, 70 m² is an industrial workshop, 15 m² is a warehouse, the remaining 15 m² is utility rooms and a bathroom. For large production, an area of 600 m² will be sufficient.

The room where disposable plastic food utensils will be produced must have the following parameters:

- 3-4 m – minimum ceiling height;

- the floor is poured with concrete or tiles are laid on it;

- three-phase electrical network;

- the presence of ventilation ducts, sewerage and water supply;

- treating walls with fire-resistant liquids up to 2 meters from the floor.

The plant should also be equipped with utility and storage facilities.

What raw materials need to be purchased?

Raw materials for disposable tableware must be of high quality. You will need polystyrene, it is sold in granules, its price varies within 25 thousand rubles per ton. In order for the products to be colored, you should buy color additives. Another material is also needed for the production of disposable tableware - polyethylene film. If you compare store shelves with plastic and paper tableware, you will notice that the cost of the latter is quite high, so the demand for it is somewhat lower than for its plastic counterparts, which is why the most profitable business will be the production of products from thermoplastics.

Raw materials for disposable tableware must be of high quality. You will need polystyrene, it is sold in granules, its price varies within 25 thousand rubles per ton. In order for the products to be colored, you should buy color additives. Another material is also needed for the production of disposable tableware - polyethylene film. If you compare store shelves with plastic and paper tableware, you will notice that the cost of the latter is quite high, so the demand for it is somewhat lower than for its plastic counterparts, which is why the most profitable business will be the production of products from thermoplastics.

Difficulties in recruiting workers

The search for personnel can be carried out through advertisements on the Internet and newspapers, but finding responsible employees in this way is quite difficult. There are no special training courses for managing the production of disposable tableware. However, almost all equipment suppliers offer entrepreneurs training for their personnel in favorable conditions. You also need to conclude an agreement with them regarding the maintenance of equipment.

Selection of equipment for production

The initial question that a businessman asks is what equipment to buy for the production of disposable tableware. The highest quality lines are those produced in Germany and the USA, but their price is high, so they can be replaced with analogues from Korea. However, they have a lower production capacity. For production you will also need an injection molding machine. To obtain blank sheets from granulated raw materials, you need to purchase an extruder. You will also need molding machines for the production of disposable tableware and a compressor.

The production cycle can be complete or incomplete. The first involves melting the granules and making a film. The second excludes the preparatory stage of its production, since it is purchased as raw materials, in the form of rolls. Therefore, the following set of equipment is required:

- an automatic machine designed for stacking and packaging products;

- granulator;

- extruder

Subsequent equipment is purchased in accordance with the selected type of cookware. You will need the following products:

- automatic machine for bending the top edge;

- packaging machine;

- printers for applying images, etc.

To make thick cutlery, pourable molds are needed. A diverse assortment guarantees greater business success, so you should purchase lines that integrate with a large number of thermoforming machines. This set of equipment will allow us to produce various types of products.

Approximate cost of equipment

The price of the equipment is high; for example, the injection molding machine alone costs about 1 million rubles. Entrepreneurs estimate the cost of entering the disposable tableware market at at least 20 million rubles. This is due to the fact that it will not be possible to limit yourself to one machine if you plan not only to win your share of the market, but also to develop further. Most of the costs are the purchase of an extruder that produces sheets from granulate.

The price of the equipment is high; for example, the injection molding machine alone costs about 1 million rubles. Entrepreneurs estimate the cost of entering the disposable tableware market at at least 20 million rubles. This is due to the fact that it will not be possible to limit yourself to one machine if you plan not only to win your share of the market, but also to develop further. Most of the costs are the purchase of an extruder that produces sheets from granulate.

Disposable tableware with a custom logo can also be sold. This type of business is especially relevant nowadays for holding various kinds of celebrations, presentations and events. Glasses are an excellent advertising medium. Corporate logo on dishes helps maintain corporate style and promotes goods or services on the market.

Stages of production technology

Depending on what products are planned to be produced, there are two technologies: molding and casting. The latter method produces dishes with thick walls. The casting process takes a long time, cash. It is worth noting that the weight of a regular 200 ml cup is 3 g, while that made by injection molding weighs up to 10 g.

There is a more cost-effective technology for the production of disposable tableware, molding, with the production of up to 30 million cups per month, which consists of the following steps:

- The purchased early raw materials are sent to the extruder.

- In the extruder, the granules melt and the resulting mass is mixed. Forming the desired consistency, the viscous liquid passes through the press, resulting in a plastic sheet approximately 2 mm thick. On at this stage a uniform thickness of the future dishes is formed.

- The film is heated in a 3-meter oven.

- The resulting mass enters a thermoforming machine, where the shape of the products is formed.

- Glasses, plates and other products are fed into the trimmer, where they are cut from the general canvas using a die-cutting press.

- Film scraps are recycled for recycling, so production is waste-free.

- The trimmer distributes the product into special apparatus, who stacks it and sends it onto the conveyor belt.

- The belt transports the dishes for packaging or subsequent transformation.

Thus, the business of producing disposable tableware is profitable and profitable, but requires large financial investments.

Production of disposable tableware: market analysis + how to register a company + technological features production of disposable tableware + raw materials for polystyrene tableware + where to rent premises + search for personnel + what profit will the production of disposable tableware bring.

In the 20th century, they could not even imagine that there would be an alternative to heavy ceramic and clay cups and plates. The production of disposable tableware was a breakthrough and a world discovery.

Plates and glasses made of plastic or paper are lightweight, you can take them with you on the road, or use them on trips to nature. The price for such a product is low, so disposable tableware is thrown away after a feast without a single regret.

There is a demand for the product all year round, especially in summer period when people go on picnics, because it can become great business an initiative for Russian entrepreneurs.

We analyze the sales market

In the twentieth century, plastic utensils were imported only from abroad, so the price for such goods was too high and there was little demand. In the 21st century, a ban was imposed on the import of polystyrene products to Russia. Many businessmen took advantage of this and began to open their own production of disposable tableware.

Every year, demand from the population has only increased, and this trend - growing popularity - continues to persist.

We can conclude: a novice entrepreneur has every chance to find his niche in the production of disposable tableware.

Who is the wholesale buyer of disposable tableware:

- Public catering points.

- Street stalls selling fast food and hot drinks.

- Outdoor cafes and bars.

- Organizations engaged in catering (food delivery and organizing lunches).

- Points selling drinks from vending machines.

Supermarkets also buy disposable tableware, which then sell glasses, plates, and cutlery at retail.

Today people have learned to use polystyrene dishes not only for their intended purpose, but also to create unique products with their own hands. This allows us to reduce the harmful impact on the environment, because the product gets a second life.

As you can see, opening your own production of plastic tableware is a profitable endeavor, especially if no one is doing this in your region yet. You will be able to cover the entire region and even neighboring areas by offering them favorable prices for goods.

How to register a business producing disposable tableware?

What to choose - LLC or individual entrepreneur? Much depends on the volume of goods you plan to enter the market with.

If an enterprise aims to fill the market of one city, then it is enough. This is easy to do by collecting a minimum package of documents.

Documents for registration of individual entrepreneur:

- Application form No. Р21001 (you can download the example from the link - https://www.nalog.ru/cdn/form/4162994.zip)

- At the reception tax inspector You need to have your passport and TIN code with you.

- Pay the state fee (800 rubles). You can do this online through a special service: https://service.nalog.ru/gp2.do

- Submit an application to pay taxes according to the simplified tax system or another form of taxation at your discretion.

Do not forget to indicate in your application the activity code 25.24.2 “Production of plastic tableware, kitchen utensils, and toiletries.”

You do not need to obtain a license to organize production. However, you will be subject to inspections from the Fire Inspectorate, SES, and Rospotrebnadzor, from which you must receive a certificate of product quality and compliance with GOSTs. Without permission from supervisory authorities starting production is prohibited.

The production must have the following documents that confirm the quality of the products:

Payments to clients are carried out, in our time, most often by bank transfer, so it is worth opening a bank account and ordering a stamp in your name.

Disposable tableware production technology

Thanks to modern equipment, myself production process comes down to minimal effort on the part of a person. Most of the work is done by conveyors and presses.Let us describe the technology for producing disposable tableware in stages:

- Raw materials are brought to production in granules made of polystyrene or other substances intended for the production of disposable plastic tableware. It enters a flat-slot extruder, where the process of mixing polystyrene granules with water under the influence of heat occurs to obtain a special melt.

- The finished mixture is squeezed out through a flat slot. The shafts are made from the mass into sheets several millimeters thick.

- The sheet must enter the vacuum forming machine. It is at this stage that the material takes the form of utensils - glass, plate, fork, spoon.

- Then special equipment recalculates the amount of dishes and then packs them.

Each equipment and the tableware material itself has its own specific requirements for temperature during production, shaft power, etc. The technologist must take such details into account in order to obtain as few defective products as possible.

We will also describe in addition the technology for producing paper tableware.

Let’s make a reservation right away that disposable paper cups or plates are environmentally friendly and also not so harmful to people’s health. Unfortunately, their production is much more expensive than making tableware from plastic.

This is due to the high cost of the final product, and, as a rule, our people are accustomed to choosing cheaper goods. This is why disposable cups and plates are not as popular as .

Technology for the production of disposable paper tableware:

- A design is applied to special laminated paper (material density 120-128 g/m2), and then divided into small sheets. Their size should approximately correspond to the circumference and height of the future dishes.

- The finished sheet is wrapped around a given shape, and the seam is welded using a special machine.

- The half-finished item is removed from the mold. If it is a glass, the bottom is inserted into it and sealed in the same way.

Although the technology for producing paper tableware is much simpler than that of plastic items, the material is expensive. As a rule, paper is imported from abroad, although lately domestic producers They are also trying to provide raw materials for the production of disposable paper tableware.

Purchase of raw materials for the production of disposable tableware

Granulated polystyrene is the basis for the production of plastic tableware. Outwardly it looks like small balls white. This material is used in the full cycle of tableware production, including the stage of melting granules.

The average price of granulated polystyrene is 50,000 rubles per ton.

There is also a ready-made film made of polystyrene or polypropylene. All that is needed to make dishes from it is to shape the final product.

The price of half-finished raw materials, of course, will be higher than for just polystyrene granules. But, using film, you can save on the purchase of equipment by purchasing only a dish form and a packaging machine.

The price of polystyrene film is about 120,000 rubles per ton.

Necessary equipment for the production of disposable tableware

The production of disposable tableware is divided into two cycles - full(when purchasing polystyrene granules) and incomplete(when purchasing ready-made film for forming dishes).

We invite you to consider how much equipment for the production of disposable tableware costs at full cycle.

The line for the production of disposable tableware consists of the following equipment:

- Mixer for mixing granules.

- Sheet extruder.

- Molding machine.

- Forming press.

- Dish stacker.

- Machine for counting dishes.

- Chiller.

- Compressor.

- Crusher for processing sheets or scrap, i.e. for a waste-free production process.

The price of such a kit varies between 6-8 million rubles. You can buy it in Russia or order it from foreign partners. To save money, you can purchase a used line, but in this case you will not have a guarantee for servicing the equipment.

If you want to produce glasses and plates using an incomplete cycle, you only need a forming line and a machine for packaging dishes. In this case, the purchase of equipment will cost 1-2 million rubles.

At the same time, in 1 hour of operation the machine will be able to produce up to 150,000 glasses, but, unfortunately, the strength of such dishes will not be at the highest level. But in 1 hour of operation, the equipped equipment can produce 30 thousand glasses and approximately the same number of plates, spoons, and forks.

Don’t forget to add comfort to production - buy furniture for the staff, arrange an office for the technologist and accountant. All working personnel must be in uniform, have respirators, and goggles so that harmful substances do not spoil their health.

This expense item will amount to approximately another 150,000 rubles, but you should not save on the comfort of your subordinates.

Finding a suitable workshop

It is best to locate a workshop for the production of plastic tableware outside the city. Firstly, because the rent or purchase price of a building there will be significantly lower than in the urban area. Secondly, the production of plastic utensils is a hazardous industry; residents of nearby houses can file a complaint and complicate your work, or even prevent you from opening a workshop.The working area should be approximately 100-150 m2. When choosing a premises, a lot depends on the volume of products produced, so take this fact into account before you start searching for the right workshop.

The production facility should consist of the following rooms:

- Workshop with equipment.

- Warehouse finished products.

- Warehouse for raw materials.

- Staff room.

- Toilet.

- Office for administrative staff.

Industrial equipment consumes a lot of electricity, so make sure that the electrical network is three-phase

and not less than 380 V.

In addition, the workshop must meet the following standards:

- The floor is concrete or tiled.

- 1.5 meters of walls from the floor level must be tiled or covered with other material that is considered fireproof.

- Due to the massive equipment, ceilings must be at least 4.5 meters high.

- Be sure to install powerful ventilation, supply water and adjust the gas supply to heat the room.

You will have to pay about 80,000 rubles for rent every month. The price is average; much of its determination depends on the renovation, region, distance from the city, availability of communications, etc.

You will also pay about 50,000 rubles for utility costs - electricity, gas, water, garbage removal.

Personnel for the production of disposable tableware

During the first months of the company's activity, the production director can take responsibility for product sales and accounting. This way you will save on wages for two positions at once. If the founder cannot cope with all the responsibilities, then it is worth hiring an assistant or specialist.

As for the line workers, they will have to be trained independently, because there is no such specialty. Equipment suppliers can provide you with training. Therefore, it is best to hire people in advance so that by the time the line is installed they are already on staff and everyone can learn how to use the equipment.

You can’t do production without a technologist. He must control the entire production process, purchase raw materials, monitor the supply of materials to the compress, etc. In addition, hire those who will take care of accounting at the warehouse of goods and raw materials.

| №. | Staff member | Number of staff | Salary (RUB/month) |

|---|---|---|---|

| TOTAL: | 173,000 rubles/month | ||

| 1. | Technologist | 1 | 25 000 |

| 2. | Accountant | 1 | 15 000 |

| 3. | Accountant | 2 | 24 000 |

| 4. | Line Operator | 6 | 60 000 |

| 5. | Loader | 1 | 9 000 |

| 6. | Driver | 1 | 9 000 |

| 7. | Cleaning woman | 1 | 6 000 |

| 8. | Equipment adjuster | 1 | 25 000 |

Depending on the scale of production, the number of personnel may vary.

Production of disposable tableware.

What equipment is used? Technology

production process.

Calculating the profitability of disposable tableware production

We invite you to pay attention to the full production cycle of tableware made from granulated polystyrene. Creating such a business will not be easy from a financial point of view, because you will have to make a lot of capital investments. But the profitability of this business will be much higher.

| Capital investments | Monthly expenses | ||

|---|---|---|---|

| TOTAL: 7,460,000 rubles | TOTAL: 8,229,080 rubles | ||

| Equipment purchase | 7 000 000 | Renting premises | 80 000 |

| Workshop setup | 150 000 | Staff salaries | 173 000 |

| Opening an individual entrepreneur and preparing documentation | From 10 000 | Purchase of raw materials (granulated polystyrene) | 5 000 000 |

| Buying a gazelle for transporting goods | 300 000 | Public utilities | 50 000 |

| Payment of taxes | 2 926 080 | ||

Now let’s calculate how many products the production can produce in 1 month of work (24 shifts) with an 8-hour work schedule:

Calculation of the cost of disposable tableware:

- To produce 1 million pieces. utensils (glasses, spoons, plates, forks are taken into account) made of polystyrene, you will need approximately 4 tons of granular material. As a rule, half of the neglected raw materials are waste; they are ultimately needed again for secondary products, so for 1 million products it is worth purchasing 8 tons of polystyrene.

- To ensure production operation for 1 month, you need to purchase approximately 200 tons of polystyrene. The purchase of raw materials will cost about 10 million rubles.

- The price of a glass (200 ml) and a flat plate is about 1.2 rubles. The price of a spoon and fork is about 50 kopecks.

- If the goods are fully sold, production revenue will be 19,507,200 rubles.

- Net profit will be 1.2 million rubles.

- To cover all the costs of purchasing equipment, you need to work for 9-12 months. Only then can we talk about making a net profit.

All calculations are approximate, because no attention was taken to the fact that the products would not be completely sold on the market. However, if you properly organize the production of disposable tableware, then success will come, and with it prosperity.

Useful article? Don't miss new ones!

Enter your email and receive new articles by email

Nowadays, there is a constant demand for disposable plastic tableware, which means we need to open production. This activity especially increases with the onset of summer, when many people go outdoors. But is she really that popular?

Disposable plastic tableware is so popular that Abercade Consulting predicts an annual increase of about 5-6% in the consumption of such disposable tableware by residents of our country. On at the moment the use of polymers per person is $70 per year, and this is tens of times less than in Europe and America. Every year it is produced for approximately 40 million dollars, of which most These are glasses, plates and cups. More than half of the goods are purchased in major cities and the capital. Large quantities cafes use plastic utensils fast food, mobile carts, tents. According to Natalya Chaloy, an employee of NPO Polymer, production plastic products remains one of the most profitable businesses(30-50%), and all investments can be recouped in two years. But plastic recycling is not cheap thing and requires serious consideration.

Success story

In the 50s, there was a massive development of fast foods in the USA, which led to the need to use special utensils. By 1960, William Dart created the production of plastic tableware by the Dart Container Corporation. This company still occupies a leading position in the United States.

Until about 1998 Russian market disposable tableware came only through imports, since own enterprises there was no production. At the moment there are practically no imports in our market.

Production equipment

In order to start producing disposable tableware, you need to purchase equipment called an injection molding machine. Its price ranges from 35,000 to 1,000,000 US dollars. There are many companies supplying such equipment. Equipment from German and Austrian companies is more common. It is possible to purchase used equipment, this can be a significant savings.

At the second stage, it is necessary to purchase an extruder; it produces sheets for disposable tableware from granulate, and two thermoforming machines. If you take such used equipment, then they total cost will be up to $200,000.

However, do not forget about the costs of premises, finished product warehouses, raw materials, and staff salaries.

Despite big investment V this business, there is a high probability of receiving disposable plastic tableware from the production good income. An example is the company “Fraht Holding” - it produces packaging for dairy products. With a huge investment, the payback period was 1 year and 10 months with a monthly profit of up to $30,000.

Raw materials for making plastic and paper

Most plastic disposable tableware is made from polystyrene and polypropylene, while paper tableware is made from laminated cardboard. This cardboard is an environmentally friendly material, but more expensive than previous ones.

Can also be made from recycled materials. Such disposable tableware will be cheaper. There are many companies that collect, sort and deliver recyclable materials to the facility for processing.

Who among us has not been to a picnic? Starting in early spring, all people strive to spend more time in nature. Plastic dishes become indispensable for such trips. It is light, comfortable and accessible to everyone. Its sales volumes are growing every year. Steadily growing demand makes the production of plastic tableware profitable and promising business.

- How much money do you need to start a business producing disposable tableware?

- What equipment to choose for making disposable tableware

- Disposable tableware production technology

- How much money do you need to start producing plastic tableware?

- How to choose equipment for the production of plastic tableware

- Plastic tableware production technology

The demand for these products in Russia has some seasonality. In summer and spring it is higher, but in winter stable sales will be ensured by agreements with lunch delivery companies, catering companies, snack bars and vending machine owners. When working properly with wholesale buyers, there is no need to worry about income during the winter months.

How much money do you need to start a business producing disposable tableware?

To start in this niche you will need at least 500 thousand dollars. The amount is quite large, so they usually attract investors or bank loans. If you buy not new equipment, you can invest up to 200 thousand dollars. In general, the price of devices in Russia largely depends on the brand and manufacturer.

What equipment to choose for making disposable tableware

The most famous line manufacturers are German and American enterprises. Prices for these brands are high and vary depending on the power. For a novice businessman in Russia, we can recommend equipment from Taiwan or Korea for the production of disposable tableware. It also has different power levels. The production line consists of the following components:

| 1 | Injection molding machine. It works with materials such as polystyrene and polypropylene. |

| 3 | Extruder. It produces sheets of plastic from granular material, ready for further molding. Typically a roll has a diameter of 800 mm and a weight of about 200 kg. The thickness of the plastic, its color and width are set by the operator. Moreover, the overall dimensions are usually cut off after the material has hardened, after exiting the extruder. This waste is recycled for further production. The thickness of the plastic is directly related to the quality and technological capabilities of producing finished disposable tableware. The thicker the canvas, the deeper the drawing can be done at the next stage. For example, to make a glass 155 mm high, the material must be rolled to a thickness of 1.1 mm. For smaller disposable tableware, you can use plastic with a parameter of 0.6 mm. The quality, further purpose and cost of the product depend on all these dimensions. |

| 4 | Molding machines. In them, under the influence of temperature, the dishes themselves are made. Bobbins of plastic are installed on them. The material is heated and fed into the mold. Here it not only stretches, it must form and cool. The molding machine also removes unnecessary elements of the product. The finished dishes are blown out of the mold and accumulated on a special rack. |

Disposable tableware production technology

The technology is called the pneumatic forming method. The raw materials for production are translucent granules, 4 mm in size. Waste is added to them own production, which were formed in previous cycles. They are finely crushed and mixed with fresh granules. Typically the content percentage is about 30, but in practice technologists often develop their own standards. They depend on:

Sometimes products are made entirely from recycled materials. The equipment allows this. Plastic utensils can be transparent or colored. The dye in the composition should be no more than 1-2% of the total volume.

The last stage of the technology is quality control and packaging of disposable tableware. The equipment usually works smoothly and without failures, but it happens that “slips” occur. Such products are removed and sent for recycling.

According to experts in Russia, approximately the same amount will be needed to furnish the premises, pay staff salaries, and pay overhead costs. The full payback of the business will not occur earlier than in 2-3 years. When planning a business, you need to consider the possibility of expanding it. As we said earlier, the demand for disposable tableware products is growing every year.

Thermoforming line.

Manufacturers of disposable tableware in any country, including Russia, are mini-factories. You can look for premises for them in the industrial zones of the city. On the outskirts, renting space will be cheaper, which will reduce the cost of finished products. In addition to the main workshop where the equipment will be located, it is necessary to provide storage facilities, an office for administration and living quarters for workers.

Since all plastic utensils will come into contact with food in the future, they must be safe for humans. It is mainly used for cold products. But if thick-walled polystyrene is used for production, it will be suitable for heating in microwave ovens. The equipment allows us to produce products from polypropylene. This material is thicker and can be used more than once to store food. Containers for refrigerators are made from it. The equipment has many possibilities. It is important for a businessman in Russia to decide on the type of product even before opening a workshop. It is better to choose dishes that are not produced in the region. You can make your products special in shape and color so that they are recognizable among consumers.

How much money do you need to start producing plastic tableware?

In this area of business, the main investments will go to renting premises and purchasing expensive equipment.

The purchase of equipment occurs in several stages: purchase, delivery to production, installation and configuration. Next, you need to train the staff in the necessary skills.

Basic equipment worth purchasing:

- molds (5 - 7 pieces) from 1 to 1.5 million rubles;

- extruder – about 1 million rubles;

- compressor - approximately 600 thousand rubles;

- thermoforming machine (2 - 3 pieces) - from 1.3 to 1.6 million rubles.

Additional costs will be spent on purchasing office equipment and organizing transport transportation(300 - 400 thousand rubles). Plus the salary of production workers (workers, cleaners, loaders, director, accountant) is about 600 thousand rubles.

Result: this area business requires large initial investments. To start this business you need 5–6 million rubles.

How to choose equipment for the production of plastic tableware

Required Equipment supplied to several countries at once. The cheapest ones are produced in South Korea and China – its main priority is cost. More expensive, but an order of magnitude better quality is made in Europe (Germany and France) - it has high quality products. The most prestigious is brought from the USA - its price is slightly higher than that of its analogues, but the quality and power indicators are excellent. The cost of a set of equipment ranges from 5 to 50 million rubles. The main question when choosing equipment is financial capabilities.

Plastic tableware production technology

The technology for making plastic utensils is almost completely automatic. On necessary devices raw materials are supplied in the form of granules or rolls of paper (depending on the product being manufactured). Next automated system production passes materials through several stages of processing. For plastic or paper tableware, they differ significantly, but the manufacturing process is completely controlled by a pre-configured control system. At the output of the conveyor, a finished, already packaged product is obtained, which remains only to be sold.

The twenty-first century is a time of super technology, a healthy lifestyle and all kinds of plastic products (toys, furniture, dishes, cutlery, etc.).

Despite the fact that some technologists and nutritionists do not welcome the use of even food-grade plastic, the statistics speak for themselves - “every second person in Russia has bought a plastic cup or tableware for a picnic at least once in their life.” And there’s no need to even talk about the mass purchase of sealed plastic containers.

Considering the popularity of the product and the wide range of possible sales points, such a business project will not lose its significance and relevance for at least the next 15 years. Therefore, if you have a desire to start your own business from scratch, then it is quite possible to consider the option of producing plastic tableware.

Registration and organization of business

Choice organizational form for an enterprise directly depends on the planned output volumes. For small workshops and mini-factories it is better to choose an individual entrepreneur (Individual Entrepreneurship), and for larger production facilities - LLC.

The OKVED code for registration will be 25.24.2 - “production of plastic tableware and kitchen utensils, toiletries.”

Required Documentation

- GOST standard R 50962-96 – “Dishes and household products made of plastic. General technical conditions".

- GOST 15820-82 - “Polystyrene and styrene copolymers”.

- GN 2.3.3.972-00 - instead of SanPiN No. 42-123-4240-86 “Acceptable migration quantities (APM) chemicals, released from polymeric and other materials in contact with food products and methods for their determination."

- SP 2.2.2.1327-03 – “Hygienic requirements for the organization of technological processes, production equipment and the workplace.”

- GN 2.2.4.1313-03 - “Maximum concentration of harmful substances in the air of the working area.”

After all the requirements have been studied, you can begin to prepare other papers and documents. If you present the required number of them in the form of a list, you get the following:

- certificate of state registration;

- approval from the city sanitary and epidemiological organization.

- fire inspection permit;

- conclusion of the labor protection commission;

- sanitary books for production line workers;

- certificate of conformity for equipment;

- a distinctive quality mark for products.

Premises and equipment

The choice of premises and organization of work depend, first of all, on the type production activities using incomplete or full cycle. Most often, entrepreneurs choose the latter option with granular work. Based on this, the requirements for organizing work in the premises are as follows:

If we talk about functional zoning, it is worth observing the following order:

- production workshop;

- administrative and amenity premises;

- warehouse for storing raw materials;

- warehouse for storage and transportation of finished products;

- shower;

- locker room;

- bathroom

The list of production equipment for a standardized workshop equipment must necessarily include:

- Granulator.

- Extruder.

- Chopper.

- Punching presses.

- Edge curling machine.

- Packing machine.

- Printer for applying an image.

It is worth noting that many manufacturers do not hesitate to purchase Chinese-made equipment because of its low cost. However, his technical specifications and the possibility of exploitation “at the output” will not provide the required volume, which means they will introduce significant amendments to the existing business plan.

Raw materials and suppliers

Purchase raw materials and consumables is available in strictly limited quantities from Russian or foreign suppliers. The quality of the source material absolutely does not depend in any way on the manufacturer’s company or manufacturing technology, the main thing is that the basis for the production of plastic tableware does not contain harmful, toxic impurities.

Purchase raw materials and consumables is available in strictly limited quantities from Russian or foreign suppliers. The quality of the source material absolutely does not depend in any way on the manufacturer’s company or manufacturing technology, the main thing is that the basis for the production of plastic tableware does not contain harmful, toxic impurities.

Thus, to implement your plan you will need to purchase:

- Polystyrene.

- Polypropylene.

Production technology

The main component of everything technological process is to give maximum strength finished product. To do this:

- The processed raw materials (or finished granules) are fed into the extruder. To add color, a dye is poured into it.

- Inside the apparatus, the mass is heated and mixed, turning into a substance homogeneous in composition.

- Having reached the state of a liquid viscous mixture, the finished mass is automatically sent to pressing, where the final density of the web is brought to 2 mm.

- As soon as the canvas “grabs”, it is sent to the thermoforming machine using a remote control.

- Next, the mixture is reheated and evenly distributed among the molds, acquiring a finished look.

When all the main stages of forming the workpiece have been completed, trimming machines cut them out and redirect them to the packaging unit. After which, the products are considered ready for shipment.

Staff

The organization of any technological process requires the presence of the following specialists from the production and administrative block:

The equipment repairman is not included in this list, since when purchasing new machines, their operation is covered by a warranty for several years. Thus, repairs and other technical issues will be resolved by an invited specialist.

Sales

Selling finished products does not seem difficult or tedious. High-quality plastic tableware is extremely necessary for organizations of many types of activities, and, therefore, the demand for products will be constant.

You can conclude a mutually beneficial contract with:

- fast food cafe;

- snack bars and small cafeterias;

- industrial canteens;

- large stores;

- small emergencies;

- children's educational institutions(In some of them, plastic utensils are used for drawing classes).

Financial component of business

The profitability of the entire production is extremely high and the degree material investments, accordingly, too. However, we should not forget that at the initial stages, by setting a limit on output, you can save significantly and check how profitable this or that entrepreneurial step will be.

Cost of opening and maintaining

In order to legalize a business, you will need not only to register it, but also to make certain initial payments. These include:

In total, the total amount for opening and maintaining is at least 2,220,000 rubles.

Amount of future income

The expected level of profit from the sale of plastic tableware may exceed even the most daring forecasts. Based on known income data large enterprises and industry workshops, we can conclude that in the first few months of operation the net profit reaches 500,000 rubles. Further, this amount either increases many times or remains unchanged.

Payback period

Based on data on the profitability of the enterprise and the level of initial costs, we can approximately calculate the total payback period. In this case it is 6 months.

When deciding to open a business in the segment of “increased consumer demand,” you need, first of all, to work for the future and think through possible ways re-registration of the company. Since everyone wants to engage in a promising project, but, as a rule, no one is ready for the oversaturation of the industry sector with the same type of product.