Rice. 1. Electric spark pencil: 1 - working electrode; 2 - core; 3 - cheek; 4 - tube; 5 - insulating tape; 6 - electromagnet winding; 7 - spring; 8 - plug; 9 - connecting wire; 10 - clamp

ki. Near the front (according to the picture) cheeks to the tube, solder the end of the coil wire (PELSHO 0.5-0.6) and wind the wire turn to turn over the entire surface of the tube in 7-8 layers. The second terminal of the coil is made with a stranded mounting wire (for example, brand MGShV) with a cross-section of at least 1 mm", to the end of which a crocodile clip is soldered. The coil is protected from accidental damage by a layer of varnished cloth, on top of which a layer is wound insulation tape. After this, a spring is inserted into the tube (15-20 turns), a plug is screwed in (M5 screw), and an electrode - a steel needle with a diameter of 1 mm - is tightly inserted into the split end of the core. When working metal part, on which it is necessary to apply a drawing or inscription, is connected to one of the terminals of the step-down (5-10V) winding of the transformer, and the other terminal of the winding is connected to the alligator clip at the coil terminal. After moistening the surface of the part with kerosene, touch it with the tip of a needle. This closes the coil’s power circuit, and the resulting magnetic field pulls the core inside the tube. The circuit opens. Then the core, under the action of the spring, returns to its original state, and the needle again touches the metal. A spark occurs between the needle and the surface of the workpiece, which leaves a clear mark on the metal.

Small-sized electric spark installation

A simple electric spark installation makes it easy and quick to process small details from electrically conductive materials of any hardness. With its help, you can make through holes of any shape, remove a broken threaded tool, cut thin slots, engrave, sharpen tools, etc. The essence of the electric spark machining process is the destruction of the workpiece material under the influence of a pulsed electric discharge. Thanks to the small area work surface the tool at the discharge site is highlighted large number heat that melts the substance of the workpiece. The processing process most effectively takes place in a liquid (for example, kerosene), which washes the contact point between the vibrating tool and the part and carries away erosion products. The tools are brass rods (electrodes), repeating the shape of the intended hole. The electrical circuit diagram of the installation is shown in Fig. 3. The installation works as follows. The discharge capacitor Ci is connected by its positive voltage

To produce elements with a complex profile from difficult-to-cut metals, an electrical discharge machine is used. Its work is based on the impact of electric current discharges, which create a high temperature in the processing zone, causing the metal to evaporate. This effect is called electrical erosion. The industry has been using machines operating on this principle for more than 50 years.

Types of equipment and processing methods

The operation of an electrical discharge machine can be described as follows:: take a charged capacitor and bring its electrodes to a metal plate. During a short circuit, the capacitor discharges. A bright flash is accompanied by the release of energy (high temperature). At the point of closure, a depression is formed due to the evaporation of a certain amount of metal from high temperature.

On technological equipment implemented various types receiving electrical discharges . Among the main schemes are:

- electric spark;

- electrical contact;

- electric pulse;

- anodic-mechanical.

By implementing one of the schemes in practice, machines are manufactured. Based on the principle of electrical erosion, the following machines were produced in different modifications:

- cut-out;

- wire;

- stitched.

To obtain precise dimensions and automate the process, the equipment is equipped with computer numerical control (CNC).

An electric spark machine works using a spark generator. A generator is an energy storage device that provides an electrical impulse. For constant supply of pulses, a capacitor bank is organized.

To organize an electrical circuit, the cathode is connected to the actuator, and the anode is connected to the workpiece. A constant distance between the electrode and the workpiece guarantees uniformity of the process. When the electrode is lowered vertically onto the part, the metal is pierced and a hole is formed, the shape of which is determined by the shape of the electrode. This is how an EDM piercing machine works.

A wire EDM machine is used to produce parts from hard-alloy and difficult-to-machine parts. A thin wire acts as an electrode. When metal evaporates, oxides are formed on the surface of the workpiece, which have high temperature melting. To protect against them, the process is carried out in a liquid medium or oil. During sparking, the liquid begins to burn, taking oxygen and other gases from the working area.

Machines of this type are sometimes the only possible way to manufacture a structural element. But buying EDM equipment for infrequent jobs is a wasteful endeavor. Therefore, if the need arises, you can make an electrical erosion machine with your own hands.

Features of a homemade device

Before you start making a homemade EDM machine, you need to understand its structure. The main structural elements include:

Manufacturing a spark generator

To make a spark generator, parts can be found everywhere (in old TVs, power supply monitors, etc.). The principle of its operation is as follows:

Safety precautions when working

Since organized electrical erosion with your own hands is associated with the possibility of damage electric shock, safety precautions must be approached with full responsibility. The workpiece must not be grounded. Otherwise, an emergency will occur - a short circuit in the supply network. Capacitors rated at 400 V can be lethal with only 1000 µF of capacitance.

Since organized electrical erosion with your own hands is associated with the possibility of damage electric shock, safety precautions must be approached with full responsibility. The workpiece must not be grounded. Otherwise, an emergency will occur - a short circuit in the supply network. Capacitors rated at 400 V can be lethal with only 1000 µF of capacitance.

Connecting devices eliminates contact with the housing. To connect the capacitor to the electrode you need copper wire cross section 6−10 sq. mm. Large volumes of oil used to prevent oxide formation may ignite and cause a fire.

1. The essence and purpose of electrical discharge machining

Electroerosion- This is the destruction of the surface of a product under the influence of an electric discharge. The founders of the technology are Soviet scientist-technologists B.R. Lazarenko and N.I. Lazarenko.

Electrical discharge machining (EDM) is widely used for dimensional modification metal products- for producing holes of various shapes, shaped cavities, profile grooves and grooves in parts made of hard alloys, for hardening tools, for electrical printing, grinding, cutting, etc.

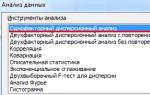

Rice. 1.9. 1 - electrode-tool, 2 - workpiece, 3 - environment in which the discharge is produced, 4 - capacitor, 5 - rheostat, 6 - power source, 1p - electric spark processing mode, 2p - electric pulse processing mode

The diagram of electrical discharge processing of materials is shown in Fig. 1.9. The circuit is powered by pulse voltage of different polarity, which corresponds to the electric spark mode (1p) and the electric pulse mode (2p). The supply voltage charges the capacitor (4), in parallel with which a discharge gap is connected between the electrode-tool (1) and the workpiece (2), which are placed in a liquid with low dielectric constant. When the voltage on the capacitor exceeds the discharge ignition potential, liquid breakdown occurs. The liquid is heated to boiling point and a gas bubble is formed from the liquid vapor. Next, the electric discharge develops in a gaseous environment, which leads to intense local heating of the part, the near-surface layers of the material melt and the melt products in the form of balls solidify in the flowing liquid and are removed from the processing zone.

2. Stages of electrical discharge machining Electric spark machining mode

The workpiece is an anode (+), that is, in this case, the workpiece is processed by an electron flow, that is, an electron streamer operates, melting the volume of the anode-part in the form of a hole. To ensure that the ion flow does not destroy the electrode tool, voltage pulses with a duration of no more than 10 -3 s are used. The electric spark mode is used for finishing, precise processing, since the metal removal in this case is small.

Electric pulse processing mode

The workpiece is a cathode, that is, a negative pulse with a duration of more than 10 -3 s is applied to it. During electric pulse processing, an arc discharge is ignited between the electrodes and the parts are processed using an ion flow. This mode is characterized by a high metal removal rate, exceeding the productivity of the electric spark mode by 8-10 times, but the cleanliness of the processing is significantly worse. In both modes, kerosene or insulating oils are usually used as the working fluid.

3. Physics of electrical discharge machining

The phenomena occurring in the interelectrode gap are very complex and are the subject of special research. Here we will consider the simplest scheme for removing metal from the processing area by means of electrical erosion.

As shown in Fig. 1.10, a voltage is applied to the electrodes 1, which creates an electric field in the interelectrode gap. When the electrodes approach a critical distance, an electrical discharge occurs in the form of a conductive channel. To increase the intensity of the discharge, the electrodes are immersed in dielectric liquid 2 (kerosene, mineral oil, etc.) There are microroughnesses of various sizes on the surface of the electrodes. The electric field strength will be greatest between the two protrusions closest to each other on the surface of the electrodes, so this is where conductive bridges from impurity particles of the liquid arise. The current through the bridges heats the liquid until it evaporates and a gas bubble (4) is formed, inside which a powerful spark or arc discharge develops, accompanied by shock wave. Flows of electrons and ions (positive and negative streamers) arise that bombard the electrodes. A plasma discharge channel is formed. Due to the high concentration of energy in the discharge zone, the temperature reaches thousands and tens of thousands of degrees. The metal on the surface of the electrodes melts and evaporates. Drops of molten metal as a result of the movement of liquid flow in the working area are thrown out beyond the electrodes and solidify in the liquid surrounding the electrodes in the form of small spherical particles (5).

From the interaction of the liquid with sections of electrodes heated to a temperature of 100-400 0C, pyrolysis of the dielectric liquid occurs at the boundaries of the plasma discharge channel. As a result, gases and asphalt-resinous substances are formed in the liquid. From gas environment carbon is released and deposited on the heated surfaces of the electrodes in the form of a thin film of crystalline graphite. At the site of action of the current pulse, small depressions remain on the surfaces of the electrodes - holes formed as a result of the removal of a certain amount of metal by the discharge.

In table Figure 1.2 shows the dependence of the amount of erosion of a steel electrode on the energy and duration of a single pulse.

Table 1.2

Dependence of the amount of erosion of a steel electrode (anode) on the energy and duration of a single pulse

Rice. 1.10. 1 - electrodes, 2 - liquid, 3 - holes, 4 - gas bubble, 5 - erosion products

After the discharge, the channel column cools down for some time and the plasma substance deionizes in the interelectrode gap. The electrical strength of the interelectrode gap is restored. The deionization time of a liquid dielectric is 10 6 -10 -2 s. The next discharge usually occurs in a new place, between two other nearby electrode points.

The duration of the intervals between pulses must be sufficient to remove erosion products from the discharge zone, as well as a gas bubble, which is the main obstacle to the occurrence of the next discharge. In this regard, the frequency of discharges decreases with increasing energy.

This happens until the discharges remove from the surface of the electrodes all areas of the metal that are within the breakdown distance at the magnitude of the applied voltage. When the distance between the electrodes exceeds the breakdown distance, the electrodes must be brought closer together to resume discharges. Typically, the electrodes are brought closer together during the entire treatment time so that the electrical discharges do not stop.

Working pulse parameters owls The main parameters of electrical pulses supplied to the interelectrode gap are their repetition frequency, duration, amplitude and duty cycle, as well as their shape, which determine the maximum power and energy. The shape and parameters of the pulses have a significant impact on the wear of the electrode-tool, productivity and roughness of the machined surface.

Let us denote the repetition rate of pulses, i.e. their number per second, by f. Then T = 1/f will be the period. It determines the period of time after which the next impulse follows.

The pulse is characterized by the amplitude value (or amplitude) of voltage and current Um and Im. These are the maximum values that voltage and current acquire during the pulse. During electrical discharge machining, the voltage amplitude varies from several volts to several hundred volts, and the current amplitude from a fraction of an ampere to tens of thousands of amperes. The range of pulse duty cycles during electrical discharge machining is from 1 to 30.

Polar effect and pulse polarity. The high temperature in the discharge channel and the ongoing dynamic processes cause erosion of both electrodes. The increased erosion of one electrode relative to the other electrode is called the polar effect. The polar effect is determined by the material of the electrodes, the energy and duration of the pulses, and the sign of the potential applied to the electrode.

The processes of voltage and current changes are oscillatory in nature relative to their zero value. In electrical discharge machining, it is generally accepted that the working or direct polarity of the pulse is that part of it that causes the greatest effect of erosion of the workpiece being processed, and the reverse polarity is the part of the pulse that causes increased erosion of the electrode-tool. The workpiece being processed is attached to the pole whose erosion effect is greater under given conditions. An electrode-tool is connected to the opposite pole. For example, with short pulses of electric spark machining, the energy is predominantly supplied to the anode, for which the workpiece should be used here (straight polarity). As the pulse duration increases, a redistribution of the heat flux occurs on the electrodes. This leads to the fact that under certain electric pulse treatment modes, anode erosion becomes less than cathode erosion. In this case, reverse polarity should be applied using the workpiece as the cathode.

Electroerosive machinability. The erosion effect of different metals and alloys, produced by electrical impulses with identical parameters, is different. The dependence of the intensity of erosion on the properties of metals is called electrical erosion machinability.

The different effects of pulsed discharges on metals and alloys depend on their thermophysical constants: - melting and boiling points, thermal conductivity, heat capacity. If we take the electrical discharge machinability of steel as one, then the electrical discharge machinability of other metals (under the same conditions) can be presented in the following relative units: tungsten - 0.3; hard alloy - 0.5; titanium - 0.6; nickel - 0.8; copper - 1.1; brass - 1.6; aluminum - 4; magnesium - 6 (the given data are valid only under specific conditions: pulse energy 0.125 J, duration 1.4-10 -5 s, frequency 1200 1/s, current amplitude 250 A).

Work environment. Most operations during electrical discharge machining are performed in liquid. It provides the conditions necessary for removing erosion products from the interelectrode gap, stabilizes the process, and affects the electrical strength of the interelectrode gap. Liquids suitable for electric spark processing must have appropriate viscosity, electrical insulating properties, and chemical resistance to discharges.

As the pulse frequency increases and the operating current decreases, the stability of the operating process deteriorates. This makes it necessary to increase the duty cycle of the pulses. The use of rectangular pulses significantly increases productivity.

Processing productivity can be increased if forced removal of erosion products from the interelectrode gap is used. To do this, liquid is pumped into the interelectrode gap under pressure (Fig. 1.11).

Rice. 1.11.

Good results gives the application of vibrations to the electrode-tool, as well as rotation of one or both electrodes. The fluid pressure depends on the depth of the hole and the size of the interelectrode gap. Vibrations are especially necessary during electric spark machining of deep, small-diameter holes and narrow slots. Most EDM machines are equipped with a special vibrating head.

Surface quality and processing precision. The metal of the electrodes is subjected, although to a local, short-term, but very intense electrothermal effect. The highest temperature exists on the surface being treated and quickly decreases at a certain distance from the surface. Most molten metal and its vapors are removed from the discharge zone, but some part remains in the hole (Fig. 1.12). When the metal hardens, a film is formed on the surface of the hole, which differs in its properties from the base metal.

Rice. 1.12. 1 - space remaining after melting the metal; 2 - white layer; 3 - roller around the hole; 4 - workpiece being processed; BL, NL - diameter and depth of the hole

The surface layer in the molten state actively enters into chemical interaction with vapors and decomposition products of the working fluid formed in the high temperature zone. The result of this interaction is intensive saturation of the metal with the components contained in the liquid medium, as well as with substances included in the composition of the electrode tool. Thus, titanium, chromium, tungsten, etc. can be added to the surface layer. During electrical discharge machining of steel workpieces in an environment consisting of liquid hydrocarbons (kerosene, oil), the surface layer is saturated with carbon, i.e., iron carbides are formed. Consequently, during electrical discharge machining, the surface of the part is hardened.

Intensive heat removal from the discharge zone through the adjacent masses of cold metal and working fluid creates conditions for ultra-high-speed hardening, which, simultaneously with carburization, leads to the formation of a very hard layer. The hardened surface layer of steel has increased abrasion resistance and a lower friction coefficient than non-heat-treated steel. The structure of the surface layer is significantly different from the structure of the base metal and is similar to the structure of the bleached layer that appears on the surface of some cast irons. Therefore, this layer is called the “white layer”. The depth of the white layer depends on the energy of the pulses, their duration and the thermophysical properties of the material being processed. With long-term high-energy current pulses, the depth of the white layer is equal to tenths of a millimeter, and with short pulses - hundredths of a millimeter and microns.

Strengthening the surface layer of metals (electroerosive alloying). One of the advantages of the electric spark method of processing materials is that, under certain conditions, the strength properties of the workpiece surface sharply increase: hardness, wear resistance, heat resistance and erosion resistance. This feature is used to increase the wear resistance of cutting tools, dies, molds and machine parts, strengthening metal surfaces using the electric spark method.

In electric spark alloying, reverse polarity is used (the workpiece is the cathode, the tool is the anode); the processing is usually carried out in an air environment and, as a rule, with vibration of the electrode. The equipment used to carry out the hardening process is small-sized and very easy to use. The main advantages of the electric spark coating method are as follows: coatings have greater adhesion strength to the base material; the surfaces to be coated do not require preliminary preparation; It is possible to apply not only metals and their alloys, but also their compositions. The processes occurring during electric spark hardening are complex and are the subject of careful research. The essence of hardening is that during an electric spark discharge in an air environment, polar transfer of the electrode material to the workpiece occurs. The transferred electrode material alloys the workpiece metal and, chemically combining with the dissociated atomic nitrogen of the air, carbon and the workpiece material, forms a diffusion wear-resistant hardened layer. In this case, complex chemical compounds, highly resistant nitrides and carbonitrides, as well as hardening structures appear in the layer. According to experts, during electric spark hardening in the surface layer of, for example, steel, the processes listed in Table 1 occur. 1.3.

Table 1.3

During electric spark hardening, the microhardness of the white layer is carbon steels can be increased to 230 MPa, the height of microroughness of the treated surface is up to 2.5 microns. The thickness of the coating layer obtained in some installations is 0.003-0.2 mm.

4. Basic technologies for electrical discharge machining of metals

Technologies for dimensional processing of metal parts.

The shaping of parts using the electroerosive method can be carried out according to the following schemes.

1. Copying the shape of the electrode or its cross-section. In this case, the shape of the workpiece element being processed is the inverse reflection of the working surface of the tool. This operation called stitching. There are direct and reverse copying methods. When copying directly, the tool is located above the workpiece, and when copying backwards, it is under it. The stitching method is easy to perform and is widely used in industry. In Fig. Figure 1.13 shows a diagram of electrical discharge machining using the method of copying the shape of an electrode-tool. During electrical discharge machining, the electrode (1) is inserted into the part, ensuring copying of the electrode.

2. Mutual movement of the workpiece and the electrode-tool. With this scheme, operations of cutting out complex-profile parts and cutting workpieces with electrodes, electrical discharge grinding and boring parts are possible.

Rice. 1.13. : 1 - electrode-tool, 2 - workpiece, 3 - liquid, 4 - vessel

Sewing windows, cracks and holes. This operation is carried out on universal machines. Using the electroerosive method, slots with a width of (2.5-10) mm and a depth of up to 100 mm are sewn. To ensure the removal of erosion products from the interelectrode gap, the electrode-tool is made T-shaped or the thickness of the tail part is reduced by several tenths of a millimeter compared to the working part. The speed of sewing cracks is (0.5-0.8) mm/min, the roughness of the treated surface is up to 2.5 microns.

Processing of parts such as meshes and sieves. Electroerosive machines have been created that make it possible to process mesh parts with the number of holes up to several thousand. The machines can simultaneously process more than 800 holes with a diameter of (0.2-2) mm in sheets of corrosion-resistant steel, brass and other materials up to 2 mm thick. Processing capacity up to 10,000 holes per hour.

Electroerosive grinding. This is one of the types of electrical discharge machining, which is used for processing high-strength workpieces made of steels and hard alloys. In this case, metal removal occurs under the influence of pulse discharges between the rotating electrode-tool and the workpiece being processed, and not as a result of mechanical action, as with abrasive grinding.

Direct and reverse copying methods have a significant drawback, which is the need to use complex shaped electrode tools. The wear of the electrodes affects the accuracy of parts manufacturing, so one electrode-tool can produce no more than 5-10 parts.

The electric spark method of complex-contour wire cutting differs favorably from copying methods in that here the tool is a thin wire made of copper, brass or tungsten with a diameter of several microns to 0.5 mm, included in electrical diagram like a cathode (see Fig. 1.14).

Rice. 1.14. : 1 - wire, 2 - workpiece, 3 - guide rollers, 4 - device for regulating the speed of wire drawing

To eliminate the effect of wire wear on processing accuracy, the wire is rewound from one reel to another, which allows all new elements to participate in the work. When rewinding, a slight tension is applied. Rollers are installed near the workpiece to orient the wire relative to the workpiece. Complex contour wire cutting is used for precision cutting of workpieces, cutting precise slits, cutting semiconductor materials, processing of cylindrical, conical external and internal surfaces.

The main advantages of electrical discharge machining with a wire electrode tool include high accuracy and the possibility of widespread automation of the process.

Electric contact processing method. Electrical contact processing of materials is a type of electrical discharge machining. Its difference is that pulses of electrical energy are generated as a result of mutual movement of electrodes or interruption of an electrical discharge when pumping liquid under pressure. Electrical contact processing can be carried out with constant and alternating current, in air or liquid (water with anti-corrosion additives). During processing, the electrode-tool and the workpiece are completely immersed in liquid or liquid is supplied into the interelectrode gap by spraying. Processing is carried out at significant currents (up to 5000 A) and open-circuit voltages of the power source of 18-40 V. The electric contact method is used to perform semi-finish turning of rotating bodies, finishing cutting, stitching of cylindrical, shaped holes and volumetric cavities, milling, and grinding. The electric contact method is especially effective when processing workpieces made of difficult-to-cut steels and alloys, as well as high-hardness cast irons, single crystals, and materials with high thermophysical properties.

The schematic diagram of the installation for electrical contact processing is as follows. The workpiece and the electrode-tool, having an axis of rotational symmetry and connected to a circuit with a power source, after contact, perform a rotational movement relative to each other.

If the conditions necessary for the implementation of electrical erosion processes are met, metal is removed from the workpiece.

Strengthening the surface layer of metal (electroerosive alloying)

One of the advantages of electrical discharge machining of metals is that, under certain conditions, the strength properties of the workpiece surface sharply increase. This feature is used to improve the wear resistance of cutting tools, dies, molds, etc. When electroerosive alloying, reverse polarity is used (the workpiece is the cathode, the tool is the anode); the processing is usually carried out with atoms of the tool-electrode in an electric pulse mode (see Fig. 1.15) in an air environment and, as a rule, with vibration of the electrode.

Rice. 1.15 Scheme of electrical discharge alloying: 1 - alloying electrode-tool, 2 - part to be alloyed

The main advantages of electrical discharge alloying are as follows: coatings have greater degree adhesion to the base material; the surfaces to be coated do not require preliminary preparation; It is possible to apply not only metals and alloys, but also their compositions.

The processes occurring during electrical discharge hardening are complex and are the subject of careful research. However, the essence of hardening is that during an electric spark discharge in an air environment, the electrode material is transferred to the workpiece (see Fig. 1.15). The transferred electrode material alloys the workpiece metal and, chemically combining with air nitrogen ions, carbon and the workpiece material, forms a wear-resistant hardened layer consisting of nitrides, carbonitrides and other hardening structures.

With electric spark alloying, the microhardness of the white layer in carbon steels can be increased to 230 MPa. The thickness of the coating layer obtained in some installations is 0.003-0.2 mm. When hardening the surface of machine parts (for example, using the IE-2M installation), it is possible to obtain a layer depth of up to 0.5-1.6 mm with a microhardness of 50-60 MPa (when hardening with ferrochrome).

A distinction is made between pure processing, which corresponds to high voltages and low short-circuit currents (up to 20 A), and rough processing (coarse alloying) at low voltages of 50-60 V and short-circuit currents above 20 A.

Work on electroerosive machines. Preparing electroerosive machines for operation consists of installing the workpiece and electrode-tool and checking their relative positions, preparing the bath for operation and the working fluid pumping system, selecting and adjusting the generator modes. The workpiece is installed and secured directly on the machine table or in a fixture. The electrode-tool is installed with its tail into the head spindle. When aligning, indicators, optical instruments, and devices are used that allow you to change the position of the tool in relation to the workpiece and the angle of inclination.

Having verified the position of the electrode tool, fill the bath with working fluid, check the operation of the pumping system, and set the required pumping pressure. Set the pulse generator mode (polarity, pulse shape, duty cycle, pulse repetition rate, average current), using the corresponding tables and nomograms. Changing the polarity of the pulse generator voltage is done by switching the current leads to the machine at the plug connector. When working with direct polarity (electric spark mode), a negative potential is applied to the electrode, and a positive potential is applied to the workpiece. To operate with reverse polarity (electric pulse mode), reverse switching is performed. Electrical parameters and operating modes are set using switches located on the control panel. Adjust the feed regulator by setting the recommended regulator voltage.

Processing materials with a dense structure manually is ineffective, as it requires a lot of labor and does not provide high accuracy. Among the installations that allow to some extent or completely (depending on the type and model) to automate the process, electrical discharge machines are less known, although they have unique capabilities, which sets them apart from the majority of their “brothers” in the machine park.

The features, operating principle and specific application of electrical discharge machines will be discussed in the material offered to the reader.

General information

- Regardless of the model, EDM machines have limitations in processing parts. They can be used to perform various operations only if the sample is made of materials of the “conductive” category (metals, alloys).

- There are several methods of electroerosive impact on a product, differing both in the method of supplying electrical discharges and in the parameters of the pulses. In accordance with this, all such machines allow the production of parts in different ways, depending on the expected result.

- An undoubted advantage of electroerosive installations is the ability to process a sample simultaneously in different directions.

What can happen as a result is shown in the diagrams (the most common options for using electrical discharge machines).

Methods for processing workpieces

- electric/pulse;

- electric/spark;

- anode-mechanical;

- email/contact.

Types of technological operations

- Strengthening the structure.

- Grinding.

- Marking.

- Cutting.

- Finishing.

- "Firmware".

- Segment.

- Volume copying.

- Processing:

- electroerosive abrasive;

- anodic-mechanical;

- electrochemical;

- combined.

Capabilities of electrical discharge equipment

The range of use of electrical erosive machines is truly enormous. The main technological operations include:

- obtaining holes (blind openings, recesses) of the most complex configuration, if necessary, with threads;

- sampling of material to any depth from the internal surfaces of samples;

- performing operations that are impossible or economically impractical to carry out on other types of machines (lathes);

- production of parts from materials that are difficult to process with traditional tools (for example, titanium and alloys based on it).

The operating principle of electroerosive type machines

Despite the difference in the design of the equipment and the implemented methods of electrical discharge machining, the operating principle remains the same.

Conventionally, the process can be divided into two technological stages.

First. Under the influence of pulse discharges arriving “through the plasma channel” (10), the structure of the sample (2) in this area is destroyed. They appear at a certain moment when the electrode (4), which is the working tool of the machine, approaches the workpiece. Electrical energy is converted into thermal energy, and as a result, the metal (alloy) melts in the area required by the specifications.

Second. Since both the part and the electrode are immersed in a container with a special composition (most often it is oil), the metal partially evaporates from the high temperature, and the remaining melt is removed from the working area.

Depending on the implemented processing method and the engineering solution in the design of the machine, the parameters of the pulses, the technology for their generation and a number of other factors in different models of electrical discharge installations may differ. But the principle of operation of the equipment remains the same.

The applied voltage “breaks through” the gap between the electrode and the “blank”, resulting in the formation of a so-called “plasma channel” characterized by high temperature. At the base of this “column” a melt of metal appears, which is removed from the working area.

In principle, such a “miracle machine” as an electrical discharge machine can be made independently. But the apparent ease of assembly is deceptive. Before you get to work, you should evaluate your strengths. The main difficulty that the “home craftsman” will face is the installation (and before that the accurate calculation of parameters) of the spark generator. In addition, the operation of this machine requires special care, since the container with oil can ignite at any time. The author does not intend to dissuade the reader from self-made household electroerosive machine, but I simply have to pay attention to a number of points.