Rocker mechanism

TO category:

Mechanical Engineering

Rocker mechanism

Rocker mechanisms, which are also a type of articulated four-bar, are widely used in technology. In these mechanisms, the crank is fixed motionless (it is a stand), and the connecting rod turns into a crank and, rotating, will cause the slider and, consequently, its guide to rotate. In this case, the slider will move forward along the guide.

Rice. 1. Rocker mechanism with rotating rocker:

Such a mechanism has four links: a stand, a crank, a rocker stone - a slider and a rocker. This mechanism is called a rocker mechanism with a rotating rocker. If the rocker is replaced by a cylinder, and the stone by a piston, we get a rotating cylinder mechanism used in pumps and compressors.

As can be seen from Figure 1, in one full turn crank (and therefore the slide or cylinder), the stone (or slider) will make a complete double movement, and its stroke, as before, is equal to the distance between the dead points, i.e., the distance between the hinges of the rack (the previous radius of the crank).

Thus, the mechanism of the rotating link was obtained as a result of the transformation of the crank mechanism and, in terms of the nature of the relative movement of the links, is completely similar to it.

The driving link is a crank that rotates uniformly around an axis. In this case, the rocker deflects to the greatest angle when the crank reaches its extreme positions, i.e., when it becomes perpendicular to the axis of the rocker (slider).

The swinging link is used in steam engines of a locomotive, in planing and other machines. A cross-planing machine with a swinging link works on this principle (Fig. 105).

The slide has a slot at the upper end into which the slider hinge fits, with a cutter attached to it.

The drive link (crank) rotates uniformly counterclockwise. In this case, the rocker stone, being in the upper position, moves the upper end of the rocker, and with it the machine slide from right to left, and the cutter goes through the working stroke, i.e., removes chips.

When the stone goes down, the upper end of the slide goes back, from left to right, together with the slider and cutter, i.e., it runs idle, since the chips are not removed.

Rice. 2. Rocker mechanism with swinging rocker:

1 - stand; 2 - crank; 3 - drawstring; 4 - slider.

The ability to reduce idle time is the main advantage of the rocker mechanism compared to the crank mechanism.

Rice. 3. Rocker mechanism of planer:

1 - drive shaft; 2 - drive gear; 3 - driven gear; 4 - lever; b - cutter; 6 - hinged connection between the link and the lever; 7 - crank slot; 8 - crank pin; 9 - slider (rocker stone); 10 - drawstring; MN - working stroke; NM - idle speed.

Rocker mechanism a hinge mechanism in which two moving links - the rocker and the rocker stone - are interconnected by a translational (sometimes rotational with an arc rocker) kinematic pair (See Kinematic pair).

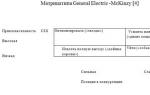

The most common flat four-link gears, depending on the type of the third moving link, are divided into groups: crank-rocker, rocker-rocker, rocker-slider, and two-link. Crank-slide mechanisms can have a rotating, swinging or translational-moving linkage (see Crank mechanism) .

Rocker-yoke mechanisms, obtained from the previous ones by limiting the angle of rotation of the crank, are performed with a swinging ( rice. 1

, a) and translational-moving ( rice. 1

, b) backstage, used to transform movement, and also as a so-called. sinus mechanisms ( rice. 1

, c) calculating machines. Rocker-slider mechanisms are intended to convert rocking motion into translational motion or vice versa, and are also used as a tangent mechanism in computing machines. Two-stage mechanisms are used in machines ( rice. 2

), ensuring equality of the angular velocities of the wings at a constant angle between them. This property is used, for example, in Coupling x ,

allowing displacement of the axes of the connected shafts. Complex multi-link valves are used for various purposes, for example, in systems for regulating the filling of engine cylinders internal combustion, reversing mechanisms of steam engines, etc. N. Ya. Nyberg.

Great Soviet Encyclopedia. - M.: Soviet Encyclopedia. 1969-1978 .

See what “Screw mechanism” is in other dictionaries:

A mechanism with lower kinematic pairs, which includes a rocker. Sine and tangent mechanisms have found application. In these mechanisms, the movement of the rocker (see figure) is proportional to the sine or tangent of the crank rotation angle. K. m. are used... ... Big Encyclopedic Polytechnic Dictionary

The lever mechanism, which includes a rocker... Big Encyclopedic Dictionary

rocker mechanism- Lever mechanism, which includes a rocker. [Collection of recommended terms. Issue 99. Theory of mechanisms and machines. Academy of Sciences of the USSR. Committee of Scientific and Technical Terminology. 1984] Topics: theory of mechanisms and machines General terms ... Technical Translator's Guide

Part of the steam distribution mechanism of a steam locomotive, which serves to move the internal steam distribution organs (spools) and to change these movements both in size and direction using reverse. Changing movements by... ...

Lever mechanism, which includes a rocker. * * * ROCKET MECHANISM ROCKET MECHANISM, a lever mechanism that includes a rocker (see ROCKET) ... encyclopedic Dictionary

rocker mechanism- Lever mechanism, which includes a rocker... Polytechnic terminological explanatory dictionary

rocker mechanism- coulisse mechanism, inverted slider crank mechanism A lever mechanism that includes a crank. Code IFToMM: Section: STRUCTURE OF MECHANISMS... Theory of mechanisms and machines- has two eccentrics and two eccentric rods connected to the ends of a curved rocker, with the concave side facing the spool. The rocker is described by a radius equal to the length of the rocker link, due to which the intake advance at all cutoffs is not... ... Technical railway dictionary

IN construction machines To convert rotational motion into other types of movements in order to transfer this movement to the working body, various mechanisms are used.

Rack and pinion mechanism, screw and rocker

In construction machines, various types of motion are used to convert rotational motion into other types of motion in order to transfer this motion to the working body. mechanisms.

Rack and pinion mechanism

Design: drive gear and driven rack.

Used to convert rotational motion into translational motion.

Design: drive screw and driven nut.

Used to convert rotational motion into translational motion.

Design: driving cam and driven rod with spring.

Design: eccentric, connecting rod, slider.

Used to convert rotational motion into reciprocating motion.

Design: drive crankshaft with a curved pin, driven connecting rod, slider.

Used to convert rotational motion into swinging motion of the scenes.

Design: drive disk, slider, driven rocker.

Used in concrete pumps.

Maltese mechanism It is used to convert continuous rotating motion into intermittent rotating motion.

Design: driving disk with lever, driven maltissa.

Ratchet mechanism used to convert rotational motion into intermittent rotational motion, but with stopping and braking.

Design: the driving element is a ratchet, the driven element is a pawl (stopping element).

Rocker mechanism

The rocker mechanism is a lever mechanism that includes a rocker. Widely used in various machines, machine tools and other equipment different kinds rocker mechanism:

1) rocker-slider mechanism;

2) crank mechanism;

3) two-stage mechanism;

4) rocker-rocker mechanism.

Rocker-slider mechanism – a four-link lever mechanism containing a rocker and a slider with a fixed guide. Such a mechanism serves to convert the rocking movement of the slide into the translational movement of the slider or, conversely, the translational movement of the slider into the rocking movement of the slide.

Crank mechanism - a four-link lever mechanism, which includes a crank and a rocker. This mechanism serves to transmit and convert the rotational movement of the crank into the rotational or rocking movement of the rocker and, conversely, the movement of the rocker into rotation of the crank. The crank mechanism is used very widely in planing, slotting machines, packaging machines and other machines.

Two-stage mechanism– a four-link lever mechanism, which includes two scenes.

This mechanism serves to transmit rotational or rocking motion from one scene to another; used in compensating clutches (due to the fact that the gear ratio of the two-stage mechanism is constant and equal to unity).

In this mechanism, the scenes interact through an intermediate link - a connecting rod.

From the book Great Soviet Encyclopedia (GR) by the author TSB From the book Great Soviet Encyclopedia (KA) by the author TSB From the book Great Soviet Encyclopedia (KR) by the author TSB From the book Great Soviet Encyclopedia (CU) by the author TSB From the book Great Soviet Encyclopedia (MA) by the author TSB From the book Great Soviet Encyclopedia (ME) by the author TSB From book Great encyclopedia technology author Team of authors From the author's bookRocker-yoke mechanism The rocker-yoke mechanism is a four-link lever mechanism, which includes a rocker and a rocker. This mechanism serves to convert the rocking motion of the input link (rocker arm or rocker). Rocker and rocker

From the author's bookCam mechanism A cam mechanism is a mechanism that includes a cam. In various sectors of the industrial and economic complex of Russia, cam mechanisms in different versions are widely used. Option one: in the mechanism the cam has a working

From the author's bookRocker mechanism Rocker mechanism is a lever mechanism that includes a rocker. In various machines, machine tools and other equipment, various types of rocker mechanisms are widely used: 1) rocker-slider mechanism; 2) crank-yoke

From the author's bookMechanism A mechanism is a system consisting of several elements (or links) and designed to convert the movement of one or more solid elements into the required movements of other elements of the system. The mechanisms are characterized by: 1) mechanical

From the author's bookLever mechanism A lever mechanism is a mechanism whose links form only rotational, translational, cylindrical and spherical pairs. An example of a lever mechanism is a cam-lever mechanism - a device that is a connection

From the author's bookRatchet mechanism A ratchet mechanism is a device in which relative movement of the links is possible only in one direction, and in the other direction the links of such a mechanism interact due to the pressure of their elements and cannot move relative to each other

From the author's bookLantern mechanism A lantern mechanism is a mechanism that has a lantern gearing in the form of gearing through cylindrical circular elements - lanterns and teeth with a mating profile. An example of a lantern mechanism is a lantern gear, in which

From the author's bookHinge mechanism A hinge mechanism is a mechanism that has in its design one or more hinges in the form of links - rotating pairs. Hinge mechanisms are divided into: 1) two-link (the simplest); 2) three-link; 3) four-link. Four-link

From the author's bookJump mechanism A jump mechanism is a device that provides periodic, intermittent movement of the film strip in the film channel during film projection or shooting and printing. A jump mechanism is a device for filming, film projection