Dear colleagues! At the end of each year, we traditionally sum up the activities of the Russian Association of Water Supply and Sanitation, analyze the results and achievements of the professional community in the development of the water supply and sewerage sector.

The outgoing year 2019 turned out to be important for the industry, as we began to implement the Ecology national project, three federal projects of which directly relate to the water supply and sanitation sector.

New Year's address from RABB Executive Director Elena Dovlatova to the industry community

“Today, in individual cases, when, for example, there really are certain water stations below the proper technical and economic level, to increase (tariffs - editor's note) possible, but only with the permission of the Government and the FAS. In addition, long-term tariffs will now be established - for a period of 5-10-15 years. There is no point in establishing new 43 thousand tariffs every year, which is what we do with regional commissions.”

Igor Artemyev, Head of the Federal Antimonopoly Service

“Our main goal is to provide Russians with affordable and high-quality housing and utility services. For this purpose, we have proposed two scenarios for the development of the industry, basic and target. After we have finalized the draft document, taking into account the proposals of colleagues from other federal authorities, the Government Russian Federation a decision will be made on what scenario the industry will develop in the next 15 years. Much in this matter, of course, depends on financing, attracting investment and budget support.”

“The budget should pay attention to the modernization of housing and communal infrastructure. We continue to work on full or partial replacement of worn-out equipment, which is what causes most accidents to happen. To make it easier for the regions to find money for this, we provide additional support from the Housing and Communal Services Reform Assistance Fund. “Starting this year, we resumed the program to support the renewal of heat and water supply systems, extending it to cities with a population of up to 500 thousand inhabitants.”

Dmitry Medvedev, Chairman of the Government of the Russian Federation

“The existing tariff regulation in the country is the main problem why businesses are not so actively investing in housing and communal services. The position of the ministry is that with today’s system of tariff regulation, we must rely on budget support.”

Vladimir Yakushev, Minister of Construction and Housing and Communal Services of the Russian Federation

"To the Ministry economic development of the Russian Federation together with the Ministry of Construction and Housing and Communal Services of the Russian Federation with the participation of authorities state power interested subjects of the Russian Federation to ensure the adoption of measures to improve the mechanism for attracting foreign investment in the field of water supply and sanitation"

Vladimir Putin, President of the Russian Federation

“Perhaps we should think about creating some kind of body - I myself do not fully understand its functional direction of activity - which would deal with the purity of water in all its aspects on on an ongoing basis, and not once a year at the congress"

Sergey Ivanov, Special Representative of the President of the Russian Federation on environmental issues, ecology and transport

Projects of industry regulations

Draft Federal Law on standardized connection rates

Government Decree on approval of the basic principles and procedure for applying in the field of water supply and sanitation the method of comparison of analogues using reference values of costs for the transmission of electrical energy and gas transportation

On amendments to the orders of the Ministry of Construction of Russia on improving the procedure for conducting technical inspections of individual municipal infrastructure facilities

It's no longer a secret to anyone that Russian market pipelines for water supply with an internal diameter of up to 40 mm, the palm belongs to pipes made of polymeric materials.

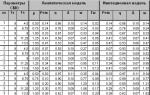

For lately modern technologies made a big breakthrough in the pipe industry. Development trend of the Russian market engineering systems indicates the active displacement of steel and including cast iron pipelines by plastic pipelines, the abundance of which currently in standard urban development is a legacy of the last century. It’s no longer a secret that in the Russian market of pipelines for water supply with an internal diameter of up to 40 mm, the palm belongs to pipes made of polymeric materials.

These include pipes made of polypropylene (PP-R), polyethylene (low, medium, high density), cross-linked polyethylene (PEX), high-temperature polyethylene (PERT), polyvinyl chloride (PVC), including chlorinated (C-PVC), polybutylene (PB), acrylonitrile butadionistyrene (ABS), as well as a number of exotic types of polyolefins. Of course, it must be borne in mind that almost each of the mentioned types of plastics can have pipe varieties reinforced with metal or fiberglass.

A large selection of materials and pipe manufacturing technologies create a choice problem. What is good for individual construction is often not applicable in multi-storey construction. It takes time to understand new technologies, and the price of a bad choice is the loss of a lot of money. After all, a pipeline system that will be used en masse under Russian specific conditions must have the best price-quality ratio.

When constructing, designing and operating pipelines, it is necessary to be guided by the norms and regulations of SNiP 2.04.01-85 “Internal water supply and sewerage of buildings” and 2.04.05-91 “Heating, ventilation and air conditioning”. Pipes used for hot water supply are designed for a maximum operating temperature of 75°C, and for heating systems, pipes with an operating temperature of 90°C are used. Working pressure up to 0.6 MPa. The warranty period is at least 25 years.

According to studies of polymer pipelines conducted by specialists from the Russian Chemical Technical University named after. Mendeleev, polypropylene (PP-R) became the first material that did not meet the requirements of serial multi-story construction for the following reasons:

- The maximum permissible temperature for a service life of 30 years cannot exceed 70˚C. With such parameters, it is necessary to increase the area of heating devices by 40% and increase the volume of coolant in the system, which will lead to an increase in pipeline diameters.

- A high coefficient of elongation when heated leads to the need to install expansion loops, which eliminates the possibility of hidden pipeline installation, i.e. Wiring is possible only in niches and behind false walls.

- Welding joints requires special skills when working with the tool and does not exclude violations of the installation technology (overheating, narrowing of the diameter).

- Different coefficients of linear thermal expansion of plastic and welded steel sleeve end fittings (for connecting other parts of the system through pipe thread) inevitably lead to a violation of integrity and, as a consequence, to the formation of a leak.

- Pipes do not bend, which increases the amount of waste, requires the installation of unnecessary connections and creates inconvenience during transportation and storage.

- Pipelines made of polyvinyl chloride (PVC) have a low coefficient of linear elongation, which makes it possible to do without expansion loops, but at a temperature of 95˚C the service life of PVC pipes is 1 year.

Metal-plastic pipes (PEX-Al-PEX) are not used in multi-story construction because:

- The heterogeneity of the wall of composite pipes of the PEX-Al-PEX type (metal-plastic), due to different coefficients of linear thermal expansion, during the operation of the pipeline leads to delamination of its constituent layers and, accordingly, it is impossible to calculate the service life for such pipes.

- The inner layer of these pipes is made of PEX, but has a thickness of no more than 0.8 mm, in contrast to the 2.2 mm required for design loads, and this leads to a reduction in the permissible pressures in the system by 3.5 - 4 times, i.e. . up to 2 – 2.5 atm.

- Layer aluminum foil thickness up to 0.4 mm is not able to withstand the pressure of the system, and this is provided that the seam is perfectly welded, and the pipe during installation has not been subjected to repeated bending in the same place - here the foil will simply stretch out and the integrity will be compromised.

- Today there is no glue that is able to maintain elasticity and withstand significant loads, because... the coefficient of linear thermal elongation of polyethylene is 7-10 times higher than the corresponding coefficient of aluminum.

- The pipe cut must be processed with a reamer, because it becomes deformed. When bending a pipe, it is necessary to use special equipment, otherwise the nominal passage will narrow and it will “slam shut.”

- The fitting must be equipped with ring-shaped rubber gaskets (otherwise it will not be possible to compress the pipe onto the fitting), as well as a dielectric gasket that protects the contact of the aluminum foil and the brass body of the fitting - galvanic couple.

- Low maintainability - re-installation of the fitting in the same place is not allowed; it is impossible to replace a section of pipe laid in a corrugation (channel) and subsequently damaged without opening the structure of the structure.

The only material that can withstand the required loads over a long service life and has properties that meet the requirements for heating systems of multi-storey buildings is molecular cross-linked polyethylene (PEX), which has:

- The homogeneity of the wall and the strength characteristics of the material make it possible to install water supply and heating systems, including central heating, in high-rise buildings with an estimated service life of at least 50 years. In this case, it is possible to use hidden wiring, which meets modern aesthetic requirements.

- The ability to restore shape due to “molecular memory” allows you to restore the pipeline after a “break” (excessive bending) and operate the system after defrosting.

- The mechanical compression of the fitting on the pipe and the “molecular memory” of the material, which constantly strives to return the pipe wall to its original position, make the connection extremely reliable for the entire life of the system. Secondary installation of the fitting in the same place is allowed.

- The absence of seals, dielectrics or welded embedded parts made of dissimilar materials makes the connections extremely reliable and reduces the cost of products and systems as a whole.

- The variety of types and a large range of fittings, combined with the flexibility and long winding length of the coils, make it possible to minimize the number of connections and pipe waste.

- The hidden installation of an elastic pipeline in a corrugation (channel), in accordance with the requirements of SNiP, allows you to replace the damaged section of the pipe without opening the wall or floor structure.

- The smooth internal surface reduces the coefficient of hydraulic resistance by 25 - 30% and does not allow solid particles to “stick” to the walls - the pipes do not “overgrow”.

There are three ways to form three-dimensional molecular bonds that suit the purposes industrial production: peroxide (PEX-a), silane (PEX-b) and radiation (PEX-c). The strength characteristics of the materials, in general, comply with DIN standards, however, upon detailed study, it turns out that pipes made from high-density polyethylene using the silane method have increased resistance to temperature and pressure at long term operation.

For the purpose of production and widespread implementation modern systems polymer pipelines for heating and water supply in Russia and the CIS, ten years ago the BIR PEKS Corporation was created, which for the first time in Russia launched the production of pipes from molecular cross-linked polyethylene PEKS-b using equipment and raw materials made in England. Now this enterprise has mastered the joint production of press-on and compression fittings according to drawings and under the IGL - BIR PEKS trademark, and is developing and producing additional elements, fasteners, mounting units, manifold cabinets, etc.

Ten years of operating experience in the highest-rise buildings in Russia (currently up to 48 floors), in elite and municipal housing construction, have in practice proven the high performance qualities of products and technologies for installing pipelines for heating and hot water supply systems from the BIR PECS Corporation. In 2007, BIR PECS systems received support from the housing and communal services of the Republic of Tatarstan and were recommended to State customers of ministries and departments of the Republic of Tatarstan, management companies and design organizations for use.

In 2010, pipelines made of silanol cross-linked polyethylene and fittings of the BIR PEKS brand were included in the Register of new equipment used in the construction (reconstruction) of city-ordered objects in Moscow and in the Moscow Territorial Construction Catalog (MTSC - 8.18).

Today the BIR PECS corporation unites companies operating in various fields production activities. The corporation acts as a contractor for engineering work, engineering support for buildings and structures, and also has its own design bureau capable of performing the task of designing engineering support for any development complex.

BIR PEKS Company LLC offers a comprehensive solution to the design, installation and commissioning of internal engineering systems with the implementation of horizontal heating systems, hot and cold water supply using BIR PEKS brand pipelines made of silanol cross-linked polyethylene, ensuring a service life of more than 50 years at operating pressure 10 atm. and temperature range 70-90˚С.

In Russia in heating systems apartment buildings Until now, in the vast majority of cases, a single-pipe (less commonly, two-pipe) system with an upper or lower wiring circuit is used. According to this scheme, the heating devices are connected in series, and the coolant is supplied to each apartment through several risers, because of this, residents of each of the apartments in high-rise buildings cannot independently change the volume and flow rate of the coolant in the heating system, and therefore independently accurately regulate the heat transfer of the heating systems. devices. In this case, we are not even talking about the inability to maintain independent heat metering separately in each apartment.

The technical characteristics of BIR PEKS pipelines made of silanol cross-linked polyethylene make it possible to design and install a fundamentally new wiring diagram - horizontal.

When using horizontal systems, steel risers are laid in common areas and on each floor - apartment-by-apartment distribution manifolds supplying apartments, which, at a comparable cost of materials, provides the following advantages:

- The principle of apartment-by-apartment metering of heat and water consumption is being implemented, thereby solving issues of energy and resource saving.

- Maintenance and reading of metering devices is carried out without access to residential or office premises.

- Compared to vertical distribution systems, the number of risers, metering devices, KFRD, etc. is significantly reduced.

The adjustment valve on the return branch of the heating system of each apartment provides required quantity heat and protects the heating system from imbalance as a result of unauthorized intervention by a resident during work to replace heating appliances, pipelines, installation of water heated floors, etc.

The construction of single risers for heating, hot and cold water supply systems made of steel ensures their quick replacement without access to apartments and without damaging the interior decoration.

Horizontally located pipes made of cross-linked polyethylene are laid in a protective corrugation and can be hidden in the structure of the floor (in a screed) or wall (in grooves), which improves aesthetics and reduces the risk of damage. If hidden installation in the floor is not possible, it can be placed in a special plinth near the floor or in a box under the ceiling.

Thus, the BIR PECS pipeline system increases the competitiveness of finished housing, has a high level of comfort for the end consumer, meets the latest requirements and standards for energy saving, has a service life 3-4 times longer than steel pipeline systems and lower maintenance costs.

One of the factors limiting the widespread use of PEX-b polymer pipelines (silane cross-linking) was the fact that according to the highest fifth strength class of GOST R 52134-2003, the maximum operating temperature cannot exceed 80˚C for continuous operation for 10 years. pressure up to 1.0 MPa. This is due to the fact that the Table of Strength Classes was taken from ISO 15875-2003 standards, which were written for European coolant standards, where the operating temperature of the coolant does not exceed 70˚C. It turned out that the products included in the project and meeting the requirements of GOST could not meet the parameters of the coolant used in Russia (90˚C or 95˚C).

BIR PEKS pipes are certified for compliance with the specified GOST, as well as technical specifications TU 2248-03900284581-99 (NIIsantekhniki), the requirements of which are much more stringent and meet the criteria for long-term (more than 50 years) operation at a temperature of 95˚C and a working pressure in the system of 1 MPa. The corresponding changes were introduced into the technical specifications after receiving the results of the study of the Russian Chemical Technical University named after. Mendeleev regarding increased durability with high temperatures operation for pipes made of cross-linked polyethylene using various methods.

Vodokanal of St. Petersburg presented two new projects today: a new treatment unit drinking water at the Southern Waterworks and an innovative system for managing the city's water supply (block K-17) reports the official portal of the Administration of St. Petersburg. The ceremony was attended by Governor of St. Petersburg Valentina Matvienko, Director of the State Unitary Enterprise "Vodokanal of St. Petersburg" Felix Karmazinov and Deputy Minister of Regional Development Anatoly Popov . Valentna Matvienko reported that in 2006 the government of St. Petersburg decided to modernize the Southern Waterworks, one of the largest in the city. It supplies up to 900 thousand cubic meters of water per day to consumers in the Nevsky, Moskovsky, Frunzensky, Kirov and Krasnoselsky districts. Construction of the new block began in 2007. The developers of the technological solution were the Israeli company Tahal. 3 billion 100 million rubles were allocated from the city budget for the construction of this complex. “This is the most modern unit in Russia, which has no analogues. It includes a whole complex of treatment facilities. Multi-layer cleaning system allows you to achieve the most high quality water that complies with all international and Russian standards", said the governor. The capacity of the new block is 350 thousand cubic meters of water per day, which is almost 20% of the water supplied daily in the city. The unit is also unique in that it allows you to solve the problem of wash water, which is used to regularly clean the filters. Previously, this water was discharged directly into the Neva. In the new block it is being cleaned. And thanks to the transition to a closed cycle of using wash water, the negative impact on the environment is significantly reduced. By now everything construction work completed, the unit was put into commissioning. Water supply to consumers will begin at the end of 2010. Presenting the project of the K-17 quarter to journalists, Felix Karmazinov noted that similar idea has not been implemented anywhere in the world except St. Petersburg. The project has been operating in the Krasnoselsky district on the basis of the Uritskaya pumping station since 2008. An innovative water supply management system has been created here, which allows you to monitor the passage of water to each consumer in real time. The implementation of the project made it possible to optimize the operation of pumping stations, monitor their condition remotely, and eliminate excess pressure. Important results included such indicators as a reduction in average monthly energy consumption by more than 42%, a reduction in unproductive water losses by 39%, and a reduction in the number of damage to networks by 32%. The innovative system guarantees St. Petersburg residents the absence of unplanned emergency shutdowns and the opportunity to save on water bills. Valentina Matvienko reported that by mid-2011, 40% of consumers will be connected to the new innovative control system. By the end of 2012, the entire city will be included in this system. “Today St. Petersburg is leading Russia forward,” said Deputy Minister of Regional Development Anatoly Popov. He emphasized that the commissioning of a new unit at the Southern Waterworks is a positive step in the development of not only St. Petersburg, but throughout Russia. “Using the example of St. Petersburg, we see how the course of the country’s leadership towards modernization, energy saving and energy efficiency really produces positive results. When the rest of Russia is just thinking about implementing any projects, St. Petersburg puts it into practice,” said the Deputy Minister. Valentina Matvienko thanked labor collective State Unitary Enterprise "Vodokanal of St. Petersburg", designers, everyone who participated in the construction of the new block and the implementation of the innovative water supply management system for St. Petersburg.

The housing and communal services sector, with its kilometers of worn-out networks and gigantic volumes of consumed resources, today is an idle testing ground suitable for testing the latest energy-saving technologies and modern materials. Only during transportation to the consumer up to 27% of water and at least 15% of heat are lost.

However, so far innovations in housing and communal services are limited to local projects, the replication of which is hampered by the industry's long-standing sluggishness.

Know-how for a building manager

When talking about innovations in the housing and communal services sector, they most often mean devices and materials that reduce resource consumption. Without operating with accurate data it is impossible. To measure water consumption, management companies began installing flow meters with built-in temperature and pressure sensors. These figures allow us to estimate, incl. quality pipes made from new materials that do not allow leaks.

As the level of energy efficiency of the serviced areas increases, the range of solutions is even greater:

- Use of long-lasting lamps;

- Conversion of boiler houses to gas;

- Installation of condensing boilers;

- Use of infrared heating films;

- Introduction of thermal insulation materials;

- Application of solar collectors.

And the transition to drinking water purification using new filters and biotechnologies can significantly improve the reputation of housing and communal services enterprises in the eyes of consumers. Domestic inventors have a particularly large number of similar developments, but their widespread implementation is most often postponed.

What about them?

In the far abroad, where enterprises serving the public utilities sector are organized fundamentally differently than in the post-Soviet space, they have long learned to increase their efficiency economic stimulation innovations in housing and communal services. The introduction of new technologies is encouraged by preferential lending and taxation.

Foreign states insure loans aimed at the purchase of innovative solutions in housing and communal services, accelerate the depreciation of fixed assets, and the companies themselves strive to take advantage of the advantages of the territories of their location

USA: wipers are being replaced by robots

In the USA the sphere utilities is entirely under the jurisdiction of the states, whose geographical, natural and infrastructural conditions differ greatly. Therefore, for example, in Florida, which is practically not covered by gasification, they strive to save electricity in every possible way, and in some southern states there are no heating systems at all.

Managers of management companies in the USA are professionals in their field. Their task is to coordinate the work of individual contractors, since different companies are involved in repairing metering devices or replacing pumps. In an effort to save money, American utilities refuse to use cheap labor force in favor of robots. Robotic snow blowers, which can be seen on the streets of American cities, work autonomously, without human intervention, performing assigned tasks.

"Toyama Tokanawa": Housing and communal services in Japanese

Country rising sun– one of the first that comes to mind when it comes to introducing inventions into everyday life. is a necessity caused by fierce competition in all markets, and the housing and communal services industry is no exception. Whoever is more efficient makes a profit.

Tens of thousands of small entrepreneurs are engaged in servicing Japan's public utilities sector, without the usual “natural monopolies.” Management company can choose the right contractor from a long list for any type of work, be it replacing water pipes or checking the performance of the heating system. The best prepared win, and all sorts of innovations play an important role here.

In Helsinki, whose climate is very similar to Russia's, city authorities can afford to heat the streets in winter. Two streets in the capital of Finland are supplied with waste heat from residential buildings. Such surplus energy efficiency would be impossible without clear rules for the housing and communal services sector, which encourage the introduction of technological progress.

The use of innovative methods allows Finns to heat their houses with coal, gas and hydroelectricity at minimal costs, switching to reserve reserves of oil in thirty-degree frosts. Per use alternative sources energy is paid by consumers, while each citizen has the right to choose the organization that provides him with housing and communal services. Officials ensure equality of opportunity for all market participants.

Features of innovations in housing and communal services in Russia

Many people strongly associate the housing and communal services sector in Russia with the “scoop”, but not with the latest technologies. The main reason is lack of money. Funds received into the accounts of management companies within existing model Tariff formation, as a rule, is not enough to carry out capital modernization and replace the infrastructure with a more technologically advanced one.

At many enterprises in the industry, even accounting in the old fashioned way is carried out manually using calculators, which does not correspond to the complexity of the residential complexes being serviced. By refusing to innovate, company leaders cut off the opportunity to reduce costs. For example, laying pipes with an anti-corrosion coating can reduce the number of accidents, and therefore save money on their elimination.

Legislative pit

Over the past decade, Russian experts have noted the inadequacy of the existing rules for the functioning of housing and communal services, which do not provide for serious mechanisms for competition between municipal and private enterprises.

Reform of the industry is progressing at a slow pace, and enterprises are not adding more money to replace outdated equipment. Changing the laws governing the conclusion of service contracts for housing maintenance could stimulate the introduction of resource-saving technologies. Without fixing payments, management companies, as noted, sometimes do not have sufficient funds for current activities, not to mention the introduction of innovations.

Examples of innovations in Russian housing and communal services

Nowadays you won’t surprise anyone with intercoms that protect common property from antisocial individuals, or “smart” light bulbs in entrances that turn on from the sound of footsteps. However, residents of depressed municipalities can sometimes only dream of such “innovations.”

Meanwhile, one of the most progressive phenomena in the housing and communal services sector in recent years has been the development of the State Information System for Housing and Communal Services. GIS housing and communal services contains regulations, a register of licenses of management companies and other enterprises in the industry, as well as residential properties, and if necessary, owners can quickly familiarize themselves with this information, incl. about the results of inspections.

In St. Petersburg, specialists from the Smart City project office promise to introduce a blockchain-based system that will not allow management companies to overcharge citizens by manually changing meter readings. The development of this system is currently underway.

There are also more exotic projects. Thus, in Kamchatka, utility companies supply residents with natural heat from volcanoes, which is a rare example alternative energy. Due to the presence of thermal water deposits in several populated areas in the north of the peninsula there is no need to use other heat sources.

Mosvodokanal is one of the main enterprises of the city that has a positive impact on health improvement environment. The Moscow sewer system is a reliable environmental shield of the capital, ensuring the sanitary and environmental well-being of the metropolis. In accordance with the implementation of the programs adopted by the Moscow Government for the development of the water supply and sewerage system for the period until 2020, a radical reconstruction of the sewerage system is being carried out.

In conditions of water conservation and annual reduction in water consumption and wastewater disposal, priority areas of development are improving the quality of water treatment and increasing the reliability of networks and structures.

The main objectives of the development of the water supply and sewerage sector of any city are:

- accelerated modernization of network facilities - both in water supply and sewerage.

- improving the quality of drinking water preparation and waste water treatment,

- increasing the reliability and efficiency of the city’s water supply and sewerage system.

The principle of operation, which consists in carrying out restoration work when an accident occurs, the so-called “fire brigade” tactics, is currently unpromising. Accelerated modernization of network facilities using advanced methods and innovative technologies- the main measure to prevent emergency situations.

Reconstruction of city network facilities in cramped urban conditions poses a serious problem. The optimal solution was to use trenchless technologies, for which about 80% of the total volume of network reconstruction is currently being carried out.

With regard to sewerage, in recent years, in addition to the technologies for reconstructing small and medium-diameter pipelines mastered in the 90s, the most modern methods restoration of sewer collectors and large-diameter canals. The technology for restoring channels of complex shape using composite modules has been mastered.

Thanks to the use of modern materials and technologies in the restoration and replacement of dilapidated gravity networks and pressure sewer pipelines, in recent years it has been possible to prevent the occurrence of major accidents in sewer networks and pumping stations, and the trend of accidents has been steadily decreasing from year to year.

In accordance with stricter requirements for cleaning quality waste water At Moscow wastewater treatment plants, specialists from Mosvodokanal JSC constantly carry out activities to search, develop and implement modern best available technologies.

Removal of nutrients

Ultraviolet disinfection of wastewater

The main directions of development of the capital's sewage treatment plants are their reconstruction with the transition to modern technologies for nitrogen and phosphorus removal and implementation of systems ultraviolet disinfection. The combination of these two technologies makes it possible today to return water to nature that fully complies with domestic sanitary and hygienic requirements and European standards.

Another important area for the development of treatment facilities today is obtaining electricity from alternative sources. A similar source at wastewater treatment plants is the biogas generated during the digestion of sewage sludge. The conversion of biogas with the generation of electricity and heat occurs at mini-thermal power plants. Facilities of this kind, powered by biofuel, make it possible to increase the reliability of energy supply to treatment facilities, which is the key to preventing the discharge of untreated wastewater into water intakes during periods of shutdown external sources electricity.

Another important area for the development of treatment facilities today is obtaining electricity from alternative sources. A similar source at wastewater treatment plants is the biogas generated during the digestion of sewage sludge. The conversion of biogas with the generation of electricity and heat occurs at mini-thermal power plants. Facilities of this kind, powered by biofuel, make it possible to increase the reliability of energy supply to treatment facilities, which is the key to preventing the discharge of untreated wastewater into water intakes during periods of shutdown external sources electricity.