One of the most profitable directions business is manufacturing disposable tableware. People use plastic dishes when having picnics outside the city, on various trips, at children's parties, so the demand for this product is not decreasing, and this type of product will remain in demand for many years to come. The difference between this type of tableware and porcelain and glass is its light weight, ease of transportation and low price.

Our business assessment:

Starting investment - 20,000,000 rubles.

Market saturation is high.

The difficulty of starting a business is 8/10.

Reasons for choosing this niche

Many people are mistaken, claiming that the production of plastic tableware is exclusively seasonal business. In practice, entrepreneurs have proven that this type of business is year-round, the reason for this is that people use utensils intended for one use all the time.

This type of business is highly profitable. The main advantages of plastic utensils include their hygiene and safety. Using this type of plates, containers, glasses and cutlery saves time for putting things in order after various special events.

Business in the production of disposable tableware involves the use of high-tech equipment that allows you to obtain goods high quality. The production line for disposable tableware, which is located at the enterprise, allows us to produce glasses of various capacities, as well as bowls, plates of different sizes, straws for drinks, cutlery and other disposable products.

An entrepreneur should understand that there are the following types of clients:

- people buying goods for seasonal picnics, celebrations, events;

- outlet owners catering, lunch delivery services, cafes, as well as owners, drinks and oxygen cocktails.

For second clients it is carried out more often wholesale disposable tableware.

It is noted that disposable plastic tableware is difficult to sell in a “young” business at first, since it is necessary to form a customer base. Only a high quality product can attract potential buyers. It is important to hire an experienced advertising manager who can promote the business and form a customer base.

Important stages of production organization

In order for a business to make a profit, it is necessary to complete several important steps:

- register a business;

- buy equipment;

- find employees.

How to register a business?

To open a plant for the production of disposable tableware in Russia, it is necessary to legally register soybeans entrepreneurial activity by completing the relevant documents. When choosing between an individual entrepreneur and an LLC, you should focus on the expected profit from production. The form of business in the form of an individual entrepreneur is registered if it is intended small production. If an entrepreneur is planning to found big business, then an LLC (limited liability company) is formed. The advantages of the latter include greater trust of partners in the founder of the production, a simplified taxation system, as well as the possibility of receiving significant discounts on raw materials for the production of disposable plastic tableware.

To sell manufactured products, it is mandatory to obtain a certificate that confirms the product’s compliance with established standards according to GOST.

Where should the production be located?

The workshop should be located outside the city. The mini plant has an area of about 100 m². Of these, 70 m² is an industrial workshop, 15 m² is a warehouse, the remaining 15 m² is utility rooms and a bathroom. For large production, an area of 600 m² will be sufficient.

The room where disposable plastic food utensils will be produced must have the following parameters:

- 3-4 m – minimum ceiling height;

- the floor is poured with concrete or tiles are laid on it;

- three-phase electrical network;

- the presence of ventilation ducts, sewerage and water supply;

- treating walls with fire-resistant liquids up to 2 meters from the floor.

The plant should also be equipped with utility and storage facilities.

What raw materials need to be purchased?

Raw materials for disposable tableware must be of high quality. You will need polystyrene, it is sold in granules, its price varies within 25 thousand rubles per ton. In order for the products to be colored, you should buy color additives. Another material is also needed for the production of disposable tableware - polyethylene film. If you compare store shelves with plastic and paper tableware, you will notice that the cost of the latter is quite high, so the demand for it is somewhat lower than for its plastic counterparts, which is why the most profitable business will be the production of products from thermoplastics.

Raw materials for disposable tableware must be of high quality. You will need polystyrene, it is sold in granules, its price varies within 25 thousand rubles per ton. In order for the products to be colored, you should buy color additives. Another material is also needed for the production of disposable tableware - polyethylene film. If you compare store shelves with plastic and paper tableware, you will notice that the cost of the latter is quite high, so the demand for it is somewhat lower than for its plastic counterparts, which is why the most profitable business will be the production of products from thermoplastics.

Difficulties in recruiting workers

The search for personnel can be carried out through advertisements on the Internet and newspapers, but finding responsible employees in this way is quite difficult. There are no special training courses for managing the production of disposable tableware. However, almost all equipment suppliers offer entrepreneurs training for their staff in favorable conditions. You also need to conclude an agreement with them regarding the maintenance of equipment.

Selection of production equipment

The initial question that a businessman asks is what equipment to buy for the production of disposable tableware. The highest quality lines are those produced in Germany and the USA, but their price is high, so they can be replaced with analogues from Korea. However, they have lower production capacity. For production you will also need an injection molding machine. To obtain blank sheets from granulated raw materials, you need to purchase an extruder. You will also need molding machines for the production of disposable tableware and a compressor.

The production cycle can be complete or incomplete. The first involves melting the granules and making a film. The second excludes the preparatory stage of its production, since it is purchased as raw materials, in the form of rolls. Therefore, the following set of equipment is required:

- an automatic machine designed for stacking and packaging products;

- granulator;

- extruder

Subsequent equipment is purchased in accordance with the selected type of cookware. You will need the following products:

- automatic machine for bending the top edge;

- packaging machine;

- printers for applying images, etc.

To make thick cutlery, pourable molds are needed. A diverse assortment guarantees greater business success, so you should purchase lines that integrate with a large number thermoforming machines. This set of equipment will allow us to produce various types of products.

Approximate cost of equipment

The price of the equipment is high; for example, the injection molding machine alone costs about 1 million rubles. Entrepreneurs estimate the cost of entering the disposable tableware market at at least 20 million rubles. This is due to the fact that it will not be possible to limit yourself to one machine if you plan not only to win your share of the market, but also to develop further. Most of The cost is the purchase of an extruder that produces sheets from granulate.

The price of the equipment is high; for example, the injection molding machine alone costs about 1 million rubles. Entrepreneurs estimate the cost of entering the disposable tableware market at at least 20 million rubles. This is due to the fact that it will not be possible to limit yourself to one machine if you plan not only to win your share of the market, but also to develop further. Most of The cost is the purchase of an extruder that produces sheets from granulate.

Disposable tableware with a custom logo can also be sold. This type of business is especially relevant nowadays for holding various kinds of celebrations, presentations and events. Glasses are an excellent advertising medium. Corporate logo on dishes helps maintain corporate style and promotes goods or services on the market.

Stages of production technology

Depending on what products are planned to be produced, there are two technologies: molding and casting. The latter method produces dishes with thick walls. The casting process takes a long time, cash. It is worth noting that the weight of a regular 200 ml cup is 3 g, while that made by injection molding weighs up to 10 g.

There is a more cost-effective technology for the production of disposable tableware, molding, with the production of up to 30 million cups per month, which consists of the following steps:

- The purchased early raw materials are sent to the extruder.

- In the extruder, the granules melt and the resulting mass is mixed. Forming the desired consistency, the viscous liquid passes through the press, resulting in a plastic sheet approximately 2 mm thick. On at this stage a uniform thickness of the future dishes is formed.

- The film is heated in a 3-meter oven.

- The resulting mass enters a thermoforming machine, where the shape of the products is formed.

- Glasses, plates and other products are fed into the trimmer, where they are cut from the general canvas using a die-cutting press.

- Film scraps are recycled for recycling, so production is waste-free.

- The trimmer distributes the product into special apparatus, who stacks it and sends it onto the conveyor belt.

- The belt transports the dishes for packaging or subsequent transformation.

Thus, the business of producing disposable tableware is profitable and profitable, but requires large financial investments.

The production of disposable tableware is becoming increasingly important in the world. And although purchasing equipment is an expensive undertaking, and when drawing up a business plan you need to carefully analyze the market, it is still a promising project that is worth paying attention to.

It is advisable to familiarize yourself with the nuances of the work of such a workshop in practice. A novice entrepreneur without basic skills will make too many mistakes that will ruin the project at the start. But having enough experience, you can open a mini-factory for the production of plastic cups, and then gradually expand the range.

Business relevance

According to statistics, there has been an increase in demand for disposable tableware around the world within 10-15% annually. This suggests that people often prefer it. The advantages are obvious:

- Can be used once and then thrown away.

- Low price.

- With the help of multi-colored elements it is possible to create a festive atmosphere in any conditions.

- Such dishes are light and do not take up much space if you have to take them with you outdoors.

- Convenient to use for any purpose.

True, an increasing variety of such products is appearing on the market and competition among entrepreneurs is growing. On the one hand, these are Chinese suppliers of plastic tableware, the cost of which is very low. On the other hand, there is the emergence of more environmentally friendly varieties, for example, paper cups. But if you organize the production of safe and cheap products, you can conquer your niche.

First you need to decide on your main competitors, study their strengths and weaknesses. Also take into account imported plastic utensils that are still in use. in great demand. Draw up a competent business plan and think over the range of products offered. For example, disposable cups are rightfully considered the most common. different sizes and volumes. Only after this proceed to the organizational part.

Paperwork

To open a mini-workshop, you must first register as legal entity. The advantages of an LLC over an individual entrepreneur are significant:

- Such a company inspires more confidence both among suppliers of raw materials and equipment, and wholesale buyers.

- It is possible to recover VAT on purchases.

- If it fails, the company risks only its authorized capital.

- It's easier to get a loan from a bank.

When registering, indicate OKVED code 25.24.2. Various licenses are not required for activities, but the premises itself and the quality of the products produced must comply with GOSTs and the standards prescribed in SanPiN. Before starting a business on disposable tableware, be sure to study the following documents:

- GOST R 50962-96 – general technical specifications production of plastic products.

- GOST 15820-82 – clarifying the quality standards of copolymers of styrene and polystyrene, on the basis of which plastic tableware is created.

- GN 2.3.3.972-00 - adopted instead of SanPiN 42-123-4240-86, which establishes requirements and quantity indicators chemicals in similar materials.

- SP 2.2.2.1327-03 – describes process and hygienic requirements for the operation and condition of equipment.

- GN 2.2.4.1313-03 – which talks about harmful substances in the air in the workplace.

To obtain permissions for production activities from the SES, fire inspectorate and Rospotrebnadzor, you need to prepare the premises accordingly, purchase equipment and release the first batch of goods, which must undergo thorough quality control. Only after this can you begin to implement the idea in practice.

Workshop setup

When installing all the equipment necessary for the production of disposable tableware, you need to select and prepare the room in a certain way. It is important to consider the following requirements:

- The ceiling height must be at least 4.5 meters, and only in the absence of an extruder and granulator can you get by with 3.5 m.

- The floor must be poured with concrete or durable tiles laid.

- The walls are covered with fire-resistant material that can be easily washed.

- Be sure to install good ventilation.

- The electrical network must be three-phase and can withstand the high loads of all equipment.

- Don't forget about water supply, heating and other communications.

The entire building is divided into separate zones:

- working;

- administrative;

- bathroom and shower for staff;

- wardrobe;

- warehouses for raw materials and finished products.

Make sure that the workshop has convenient access roads for unloading goods. It is better to rent or purchase such premises outside the city or in its industrial part. The total area should be about 500 square meters. m.

Equipment selection

A full-fledged automated line for the production of disposable tableware consists of the following elements:

- Granulator.

- Extruder.

- Crushers.

- Thermoforming press.

- Automatic product stacking machine.

- Conveyor.

- A machine for bending the top edge of a glass.

- Printer for applying an image.

- Compressor.

- Self-filling molds for cutlery.

It is not necessary to purchase all of their varieties at once. You can build a line gradually, adding individual elements as your business develops and the initial investment returns. You can only start with an automatic product stacking and packaging machine and a thermoforming line. By purchasing ready-made rolls of thin film, you will do without installing other elements.

Please note that equipment manufacturers offer different models, capacities, and a variety of shapes, and this, in turn, significantly affects the cost. Depending on your financial capabilities and the desired volume of production of disposable tableware, you need to make a choice.

It is believed that German and Austrian devices are the most powerful and are the ones worth purchasing when creating a productive automated line that produces several million products per month. But to start, you can spend 3-4 times less and opt for Korean or domestic cars. Then production volumes will be lower, but equipment costs will also be affordable.

Raw material base

Plastic disposable tableware is made of two main components:

- Polypropylene is resistant to fats, oils, alcohol, products made from it can be placed in a microwave oven, and they are also allowed to be used for baby products. But when working with this material, it is necessary to strictly adhere to the technology parameters so that its quality characteristics do not deteriorate.

- Polystyrene - it is much easier to work with, but has lower performance during operation.

Individual entrepreneurs began to produce, but the cost of laminated cardboard and products made from it is quite high. Therefore, such a business is still losing in competition.

When searching for suppliers of polystyrene and polypropylene, you can contact several existing large enterprises that produce them. But there are certain disadvantages. With larger orders, small customers will have to wait too long for the material, which threatens frequent workshop downtime.

Therefore, it is worth establishing other delivery channels. For example, pay attention to factories that collect recyclable materials and process them. And although the quality of such material is significantly lower, this can be a way out in finding a permanent and reliable supplier. Or find a foreign manufacturer willing to offer the material at an affordable price. It is important to control the quality of the original raw materials. It must comply with GOST 10354-82.

Process

When creating plastic utensils, the material goes through the following stages:

- Polyester in the form of granules is fed into the extruder. If you want to diversify the color scheme of the product, you can add different shades.

- The raw material is heated to high temperatures, at which it begins to melt, and mixed, achieving a homogeneous mass.

- Then it is passed through a press, which ensures the thickness of the finished film is 2 mm. It is very important to ensure that the machine always produces a uniform web.

- Such a roll is sent to a thermoforming machine, which involves the creation of one or another product (glasses, plates, etc.).

- Here the material lends itself again high temperatures and due to vacuum action it acquires the desired shape.

- Next, the workpieces go to the trimmer, where they are cut to size.

- Using a conveyor, they move to a packaging machine or printer to apply a logo, design, advertising, etc.

- For glasses and plates, you need to additionally pass the products through a machine that bends the edges.

- At the end, the goods are packed into large bags.

Staff

Due to the fact that the line is fully automated, there is no need to hire a large number of people to monitor its operation. Depending on the volume of production, a different number of employees is needed. For a medium-sized workshop it is enough to have on staff:

- Technologist - specialist with higher education and experience in this field, it is quite difficult to find such a person, but its presence is mandatory to maintain product quality.

- Equipment adjusters should also be trained additionally or find professional technicians.

- Ancillary workers.

- The cleaning lady.

- Accountant.

- Client Relationship Manager.

To deliver goods to customers yourself, it is also advisable to hire a loader and driver. To save costs, you can perform some functions, for example, accounting, management, product sales, yourself.

We are looking for buyers

It is not enough just to produce a quality product. We still need to find through which channels to sell disposable tableware. From advertising, you can use all available resources - media, Internet, advertisements. But it is better to establish personal contacts with the owners:

- Catering establishments.

- Supermarkets.

- Specialized stores selling relevant products.

- Wholesale bases.

- Companies involved in food preparation and delivery.

- Vending machines.

- Larkov.

- Offices.

- Educational and other government institutions.

- Confectionery companies.

- Organizations for organizing holidays and corporate events.

- Catering agencies, etc.

It makes sense to hire a marketing and sales specialist, then the activities of your company will quickly pay off due to large wholesale orders and sales finished products.

![]() Download for free as a sample.

Download for free as a sample.

Financial part

Opening a mini-workshop for the production of disposable tableware will require large investments. Let's list the main expense items.

The cost of one unit of product is on average 0.25 rubles. If you sell disposable tableware for 0.35 rubles, then with a production volume of 10 million units per month, you can achieve a net profit of 1,000,000. Even taking into account regular deductions, after 3-4 months you can achieve full payback for the project.

Video: production of disposable tableware.

The choice of equipment for the production of disposable tableware should be approached responsibly, because demand and profit will depend on the quality of the product.

Raw materials for disposable tableware

Material used in the manufacture of containers

Initially, disposable tableware was paper. Nowadays, laminated cardboard with a density of 130–280 g/m2 is chosen for its production. Lamination is performed in a layer of 10–20 microns. Such containers are suitable for advertising or creating branded tableware. For example, in a chain of coffee shops it is important to use cups with the name of the establishment and its slogan.

Until recently, Finnish paper was the favorite. Now gaining momentum domestic production quality cardboard.

In the production of plastic utensils, they are used as raw materials. different types polymers, depending on the required characteristics of finished products and production capacity. For the full cycle, granulated polystyrene is used, which in appearance resembles foam spheres. For abbreviated production cycle use polystyrene or polypropylene film.

is an amorphous polymer thermoplastic mass made from benzene and ethylene using polymerization. The material has a fairly high gas permeability, which is why it is often used in the production of cups for fermented milk products. The disadvantage of polystyrene is fragility.

– partially crystallized polymer with thermoplastic properties. It is made from propylene by joining molecules together to form large molecules. This material is not as fragile, and its production is cheaper than polystyrene. The disadvantages of polypropylene are its complexity, which requires strict adherence to temperature, and the inability to store the polymer at subzero temperatures, which makes the raw material brittle.

Main advantages of disposable tableware

The undoubted advantages of disposable products are:

- Safety. Plastic products are made from flexible materials that cannot be injured or even broken.

- Hygiene. In catering establishments, the use of disposable tableware ensures the cleanliness of food containers.

- Saving. No need to waste time and money ( detergents, water and its heating) for washing dishes.

- Convenience. Indispensable in establishments selling takeaway food and drinks.

Required equipment and its functions

For the full production cycle of disposable plastic tableware, several types of equipment are required:

- extruder – necessary for producing polystyrene sheets;

- thermoforming machine – creates the required shape;

- compressor;

- crusher - a device for grinding recyclable materials or industrial waste;

- packing table;

- granulator.

Extruder is a machine in which polystyrene or polypropylene granules are melted. The molten mass is stirred with a screw to a homogeneous consistency. The semi-liquid material is passed through rollers and exits through a slot-shaped opening in ready-made sheets. The following points are important in high-quality models:

- Wear-resistant steel is used for the screw;

- large ratio of length and diameter of the screw;

- precision balancing of shafts and auger;

- uniform thickness of the resulting film.

Thermoforming machine heats a sheet of plastic and makes indentations of the required shape in it. For the production of forks and spoons, a different principle is used - molten polystyrene or polypropylene is poured into the prepared form. The finished products are quickly cooled, literally in a few seconds, and proceed to the packaging line.

Crusher or crusher Designed for shredding plastic film residues after stamping. The crushed plastic is sent to a granulator, where it is converted back into plastic balls.

On the packing table With low production capacity, dishes are sometimes packed by hand. But it is more efficient to use a special machine for counting finished products and their subsequent packaging.

If you have financial capabilities, the owner can purchase not individual devices, but a ready-made automated line.

Equipment for the production of tableware in full cycle includes only thermoforming machines and packaging line.

Devices for making paper cups

Making paper products for food requires different equipment.

The most important apparatus is the molding machine. The main difference between the models is the method of joining the glass seam - thermal or ultrasonic. For small production A thermoforming machine that creates a seam by heating using electricity is suitable. Such equipment is relatively inexpensive and easy to operate. The machine's energy consumption is 5–7 kW, with a production capacity of about 40 pieces per minute.

Modern models of paper cup molding machines have a variety of additional functions, improving the quality of finished products and line productivity:

- Swiss Leister system for connecting the bottom to the sides;

- pneumatic stacker of cups into tubes;

- PLC control system;

- a defect detection system that sorts out damaged products.

It is important to provide for the manufacture of lids. To produce them you will need a separate machine.

The highest quality is Japanese technology. Used equipment can cost almost 2 times less. But it is necessary to compare the risks of machine failure and the cost of their maintenance.

Nuances of choosing equipment

When deciding to invest in creating a production of disposable cutlery, you need to consider several points.

All disposable tableware must be certified

Planned production capacity enterprises. Based on it, the choice of premises, equipment, personnel selection, estimated costs for materials and resources, including public utilities, planned profit.

Workshop size. It is imperative to control these parameters so that the selected equipment fits in the room. It is important to remember about auxiliary premises (staff bathroom).

Technical characteristics of selected machines. They must match the productivity of the workshop. An important point is energy consumption and ease of maintenance and repair of devices.

The conditions and price of equipment supply are also important.

Features of the production of plastic and paper tableware

The production of disposable tableware is a multi-stage process. But its features will differ from the type of raw materials used.

The production of plastic tableware in the full cycle occurs in stages:

- Selected polystyrene foam balls are sent into an extruder, in which, when heated, they become a liquid with the consistency of sour cream. The auger mixes the raw materials into a homogeneous mass.

- This mass passes through the rollers into a narrow opening. The thickness of the plastic sheet can be adjusted by the distance between the extruder rolls. Some models have the ability to produce multilayer film.

- Utensils of the required shape are produced from the film using thermoforming equipment.

- Finished products are sent to the packaging line.

- Waste sheets, after cutting out tableware blanks from them, are sent to the crusher. From the crushed plastic in the granulator, balls are produced, which are returned to the production cycle.

All devices are quite simple. More modern modifications have full automation of processes with the possibility of minimal operator intervention. The equipment for this is both foreign and domestic. The choice usually depends on price and delivery conditions.

Paper dishes

Making disposable tableware from paper requires completely different equipment, which domestic factories do not yet produce.

A typical production scheme includes:

- supplying sheets of cardboard for the walls of cups;

- rolling paper into cylinders;

- forming sides;

- cutting out and attaching bottoms.

There are multifunctional machines for making different types disposable cutlery items. But some additions will still be required: printers for creating exclusive tableware, moldings that serve as a matrix for paper products. Blanks for forming sides are required in different sizes.

The image and inscriptions are applied to the paper at the initial stage before the blanks are formed.

Seams paper cups processed ultrasonic or thermally. Ultrasonic welding is stronger and can occur continuously with high productivity. A seam made by thermal method is less expensive.

Filter

Calculate deliveryRussian factories of disposable tableware

— catalog for 2020. 50 enterprises provided goods. Disposable tableware factories:

- "Plastic DV".

- "Atlas".

- "Artplast".

- "Bulgari Green" and others.

Manufacturers have mastered the production of plastic and paper products. Plastic products occupied 80% of the market, paper 20%. The company offered a range of products: cups, containers, plates. The production also produces glasses for drink machines. Production equipment has been modernized. Companies have mastered sales through online stores.

Manufacturing organizations have launched the production of recycled plastic products. Food manufacturers and food companies use disposable utensils everywhere. The business introduced new packaging methods and used safe raw materials. Prices for Russian products are up to 70% more profitable than imported ones.

Transport organizations will help with delivery in Moscow and the Moscow region, in federal regions and abroad. Enterprises entered their addresses and telephone numbers in the “Contacts” tab on the exhibition website. Russian manufacturer looking for suppliers, wholesale buyers. A company employee will inform you how to buy goods in bulk, download the price list, and conclude a dealer agreement. The list is being updated.

Pneumatic vacuum forming machines series JDX And JMDX- high-speed machines designed for vacuum forming of plastic products. The machines are used for the production of lunch boxes, trays, trays, trays, boxes, boxes for cakes, blisters, pastry cases, gifts, dishes, decorative and other packaging products from plastic rolls.

The machines are equipped with high-quality pneumatic and electronic components produced by companies such as NORGREN, OMRON, SIEMENS. This significantly improves the performance of the machines, makes them easier to operate and guarantees the production of high-quality products. The productivity of the machines is determined by the depth of the molded products.

Advantages of the devices:

- convenient automatic control

- precise digital time management

- quick manual and automatic shutdown

- central lubrication system, central gas regulation system

- infrared heating with individual temperature control heating elements

- secondary raising and lowering of the mold, secondary blowing, secondary vacuum function (purpose)

- Vacuum retention, electromagnetic brake

- special design solutions that ensure the creation of products with constant quality.

- separate chilled water supply system, inlet cooling and atomization

- Powerful blowing mechanism, effectively improving the performance and cooling time of the mold.

- JDX-1200B has upper and lower heating zones for the sheet of molded material, which significantly improves the quality of the final product and increases the maximum depth of its molding

- automatic cutting of molded sheets.

Raw materials used: all colored sheet materials such as PET, PVC, PS, PP, etc.; environmentally friendly sheet materials such as APET, PETG, etc.; biodegradable materials; light-degradable materials.

Additional equipment: For the operation of the devices, a supply of compressed air and water must be provided. Mechanical cutting machines and pneumatic punching presses are used for cutting products.

A less productive and flexible version of the pneumatic vacuum forming machine is a semi-automatic JDX-600.

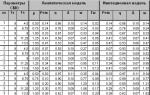

| Characteristics / Model | JMDX-1120 | JMDX-1220 | JDX-900 | JDX-1120 | JDX-1200 | JDX-600 | |

|---|---|---|---|---|---|---|---|

| A | B | ||||||

| Length of the molded area, mm. | 750 - 1120 | 750 - 1220 | 450-900 | 760-1120 | 760 -1200 | 700 | |

| Width of the molded area, mm. | 560, 600, 660 | 300-560 | 480-700 | 500-700 | 600 | ||

| Forming depth, mm. | 60 | 100 | 165 | 150 | |||

| Cycle time, sec. | 10-15 | 9-60 | 40-100 | ||||

| Max. ave., cycles/hour | 360 | 400 | 90 | ||||

| Productivity, pump vacuum, m 3 /hour | 100 | 63 | 100 | 20 | |||

| Vacuum pump power, kW, kW | 3 | 1,5 | 3 | 1 | |||

| Compressed air consumption, m 3 /min. | 0,8 - 1,2 | 0,6 | 0,8 | 0,8-1,2 | 0,6 | ||

| Sheet thickness, mm. | 0,1-1 | ||||||

| Heating power, kW | 24 | 18 | 22 | 24 | 24 +18 | 18 | |

| Water consumption, m 3 / h | 0,8 | ||||||

| Power Specifications | 380V, three-phase | ||||||

| Overall dimensions, mm. | 6400 x 1600 x 2000 | 6500 x 1600 x 2000 | 5400 x 1200 x 2200 | 7800 x 1400 x 2200 | 7220 x 1400 x 2500 | 3000 x 1300 x 2100 | |

| Weight, t. | 4 | 4,2 | |||||