Besides studying glamor, I had another purpose for being in Moscow.

I was pleased and interested to meet glassblowers whom I previously knew through correspondence or communication on the glassblowing branch of the metal forum:

http://www.chipmaker.ru/forum/186/

The most powerful glassblowing impression from visiting Moscow was the oxygen tap. Almost everywhere in Moscow, additional glass-blowing burners are used to process molybdenum glass or Pyrex (Simax). First, the additional and main oxygen is adjusted at the burner. Oxygen is then regulated by a common oxygen valve, which is separate from the burner and secured under the tabletop on the left side of the glass blower.

If you rise into the light of day from the “University” metro station, you can see the sign “Attention! Bike path."

I still don’t understand where this bike path is, but that’s not what the story will be about.

The largest workshop I visited was the glassblowing workshop of the Chemistry Faculty of Moscow State University. The head of the workshop is Alexander Viktorovich a. k. a. Alexander glass blower

One of the workshop’s most experienced glassblowers is Grigory Pavlenko a. k. a. GREGORY 777

Grigory told a lot of interesting things about glass. That complex and loaded quartz glass products crack and need to be annealed. Or about the interesting surface properties of glass. Surface layer glass, which is constantly in contact with environment and, as a result, changes its properties to be etched differently than the mass inside. To speed up etching, you need to slightly destroy the surface of the glass with fine sandpaper. That when making small Dewar flasks there is no need to secure the inner part in relation to the outer one.

In such Dewar vessels, the junction is made “in weight”

For large diameters, Gregory uses a rolling sheet made of tin, the working surface of which is covered with thermally expanded graphite foil

Grigory was kind and allowed us to record a video of how he makes the faucet

In the glassblowing workshop of the Faculty of Chemistry of Moscow State University, despite temporary difficulties, there are many young people, a worthy replacement is growing.

Ilya Sirotovsky makes a Klein bottle

Alexander Viktorovich says that in order to awaken the imagination of chemists, and to make it easier for novice chemists to place an order, a stand was made with various products that are made in the workshop

Glassblowers who make chemical glassware are no strangers to artistic impulses

Electric cutting with nichrome tape and built-in LATR. To the right is a sharpening machine for straightening glass knives

Interesting vertical flow trap with liquid nitrogen cooling

Glass blower's workplace. On the left, under the countertop, an oxygen tap shines.

Additional oxygen burner

Quartz blowing burner

Charming table. Probably Mikhail Lomonosov used it for an astrolabe

Horizontal brewing machine A-320

Collect molten glass. Using a hollow steel pipe or glass blowing tube, collect glass melt from the furnace in which the glass melt is located. The temperature of the glass melt in the furnace should be from 1380 to 1435° Celsius.

- A simple but accurate analogy is wrapping an apple in caramel. Think of the steel rod as an apple and the oven as a can of caramel. Just like slowly rotating an apple in hot caramel, the steel rod in the kiln must be constantly rotated to ensure an even accumulation of glass melt.

Form the glass. Once the glass melt is stable, transfer it to a steel rolling table and begin to shape it. Glass forming begins with rolling glass on a rolling table. It is important to obtain a symmetrical cylinder. Once you have a cylinder, continue to rotate the blowing tube to prevent the glass from dripping.

- The rolling table will take a lot of heat away from the molten glass melt, since when the glass is rolled on the table, both materials come into contact.

- If the walls of the glass melt become too thin, cool them by rolling them out on a rolling table.

- If the bottom of the glass melt becomes too fat, then place the glass again through the hole into the glass reheat furnace (designed to keep the glass in a viscous state), and focus on heating the bottom of the glass melt. While heating the glass, turn it all the time.

Make a preparation. Blow into the tube and close it with your thumb. The heat will expand the air trapped in the tube and a bubble will form. This first set and bubble is called the blank.

- Once you have a bubble with even walls, you can use the rolling table again and collect more glass. Remember to constantly rotate the rod as you move it from the rolling table to the furnace and the furnace opening.

Refill with glass melt. Collect a drop of more glass melt. Required quantity sets of glass melt depends on the desired size of the product - the larger the product, the more of them are needed.

- If you want to add a little color, now is a good time to apply it to a cooler "post" (cylindrical blank).

Form the bullet. When you have finished collecting the glass melt, moisten the newspaper and use it to form your workpiece into a pellet. Then heat it again in the oven opening. Don't forget to rotate the rod all the time!

Decide on the form. Form the product by rolling it on a rolling table while an assistant blows air through the tube into the glass melt.

- down on glass, roll out the sides, not the bottom. If the sides are colder, then when air is blown in the bubble will push out the bottom.

- If you want the bubble to move from glass, that is, to expand the walls, roll out the bottom. If the bottom is colder, then when air is blown in, the bubble will push out the walls.

Make the cuts. After molding the product, use special pliers to make a cut line on the neck. The diameter of the neck should be equal to or smaller than the diameter of the glass blowing tube. Keep rotating the tube!

Unfold the product and complete its production. This requires transferring your piece to another rod called a pontium. This is one of the most difficult operations in glassblowing. However, knowing a little professional secret makes it much easier. Find a small tool ( best option– file) and dip it in water. Carefully draw a line around the neck. This will reduce the strength of the glass and make it more fragile. After this it will be easy to separate it from the first tube.

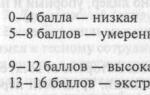

* The calculations use average data for Russia

Glass is rightfully considered one of the most interesting and impressive materials used for making souvenirs. Glass is characterized by its relatively low cost, ductility and high flexibility in processing. Glass can be used to make products of various shapes and colors, from simple tableware to real works of art that will decorate any collection. Meanwhile, the production of glass products cannot be called a simple matter. Rather, on the contrary, it is a complex process that requires the master to have extensive experience and professionalism. In addition, he must also have good artistic taste, otherwise his glass products will not be in demand. Additional benefit glass products is that due to the specifics of the process of its production, which is carried out on small businesses completely manually (and even on large factories This process cannot be fully automated), each finished product is one of a kind and inimitable. No less popular among consumers are glass jewelry, which may not be as durable as products made from natural stone, but very beautiful and original. The range of glass products is almost limitless. These can be glass bouquets, small vases, animal figurines, jewelry, zodiac signs, etc.

Manual production of glass products

The technological process of manufacturing glass products in small glass-blowing workshops involves the use of exclusively manual labor. On the one hand, this significantly complicates production and increases the cost of the product, and on the other hand, it increases the value of such a glass souvenir in the eyes of buyers. In a simplified way, the process of “manual” manufacturing can be represented as follows: first, the master heats the workpiece, which is called a glass shot, and then, using a special tool, gives it one shape or another. This procedure is not only labor-intensive, but also dangerous. It can sometimes take several hours to make one complex product.

Before starting work, you must clean workplace from dust and debris so that foreign particles do not get into the glass. Then a glass dart (glass dart) of the required shades, length and thickness is laid out on the work table in front of the master. Glass darts are sticks made of colored glass up to 40 cm long and with a diameter of three to six mm. A special burner is used to melt the glass shot. First, the master heats two glass rods to a plastic state, and then makes a part of the future figurine from this mass, giving the workpiece the required shape during the process. Other parts (eg paws, heads, tails) are made from glass rods of different thicknesses and/or colors. The same technology is used: first the glass is heated on a burner, and then small parts are attached to the base body. At the last stage, the figurine is given its final appearance by gluing ears, eyes, clothes, noses and other elements to it. Finally, the finished figurine is left to cool completely, and then checked for defects. To do this, the master or inspector simply carefully examines the product under the light. If no defect is detected, the figurine is packed and sent to the warehouse. If any mistakes were made during the work, then small cracks are clearly visible inside the figurine. Such a product is considered defective and sent for processing. Depending on the qualifications and experience of the craftsman, as well as the complexity of the figurine, its production can take from twenty minutes to several hours. Using a similar scheme, small workshops produce other souvenir and gift products, such as vases and Christmas decorations, but in this case the glass is inflated to create a cavity inside the product.

Glassblowing workshop: premises and equipment

Earn up to

200,000 rub. per month while having fun!

Trend 2020. Intellectual business in the field of entertainment. Minimum investment. No additional deductions or payments. Turnkey training.

So the size starting capital to open own production glass products directly depends on the planned production volumes. Experts say that it is better to start such production with a glass-blowing workshop with at least fifteen jobs. First of all, you will need a suitable premises. It should be spacious and comfortable enough for work. The recommended area should not be less than 50 square meters. meters, and the ceiling height is at least 3-3.5 meters. It is best to cover the workshop floor with linoleum or vinyl chloride tiles. With a soft floor covering, there is a lower risk that a glass piece that falls on the floor will break into small fragments. The arrangement of furniture and equipment in a glassblowing workshop is subject to special requirements related to the specifics of production, which must be taken into account when choosing a room. For example, work tables are positioned in such a way that the light shines work surface craftsmen fell from behind or from the side, and the distance between burners at workplaces should not be less than 125 cm.

In addition to the workroom, you will also need several utility rooms, which may be of a smaller area, the main thing is that they are isolated from the main one. In one of these rooms, grinding, sharpening and drilling machines are installed, as well as a machine for cutting tubes and workpieces, in another - compressors, and in the third - fume hoods (calibration work will be carried out here). Please note: windows and doors in all rooms, including work and utility rooms, must open outward. In addition to the equipment, shelving is installed in the workroom where workpieces, tools and finished products will be stored, as well as special vertical racks for storing glass shot. You can make such racks and racks yourself.

Gas, oxygen and air are supplied to each workplace. In most cases, glassblowing workshops use gas from the city network, which has excess pressure, or propane gas in cylinders. In the latter case, all gas cylinders are placed outside the building where the workshop is located, in a metal booth that is locked with a padlock. From the cylinders, gas is supplied through a reducer through pipes to the glass-blowing workshop. Oxygen from cylinders is also supplied to workroom through high-pressure metal pipes to the distribution board, which must be placed on one of the walls of the workshop. From the distribution board, oxygen is supplied through a reducer to each work table. Gas, air, oxygen are supplied to the burners through the corresponding branches on the line through high-pressure rubber hoses. As a rule, these hoses are secured under the tabletops and lead out through holes or cutouts in the table top near the burner. All gas and oxygen supply must be approved by Gosgortekhnadzor. The pipelines supplying gas, air and oxygen to the table are mounted on the wall and painted in different colors (red, yellow, green).

The workshop premises must be equipped with exhaust and supply ventilation. An umbrella connected to an exhaust ventilation duct must be installed above each table to remove smoke and combustion products. Centrifugal fans can be used as supply ventilation. It is not necessary, but it is highly advisable to install air conditioners in your workshop, which will help maintain a comfortable air temperature during the hot season.

Ready ideas for your business

Except daylighting the workshop will also need to be equipped with fluorescent lamps. For individual species For work, you can use special table lamps with a reflector.

In one of the utility rooms, compressors of sufficient power are installed, which will help ensure excess air pressure at the burner. For a uniform supply of air, a receiver or a strong sealed container or, as a last resort, an empty steel cylinder is used. In the latter case, you need to drill two threaded holes in the cylinder, into which short pipelines are then screwed. A pressure gauge and a spring safety valve of the PSK type are mounted at one (upper) outlet.

Ready ideas for your business

When working with oxygen, the system through which air is supplied to the workplace must be equipped with oil filters.

Metal tables for muffle furnaces are installed in the room adjacent to the workshop. Sheet asbestos must be placed on the metal surface of the table, on which, in turn, muffle furnaces with different furnace space capacities are placed ( best option– with automatic temperature control). This equipment is used for firing finished products. Above the table where the muffle furnaces are located, a marble shield with magnetic starters for each furnace is installed. If the layout does not provide for an adjacent room, then the stoves can be installed in the workshop.

In the room for mechanical processing of glass there are several grinding machines (four furnaces are enough for the above-mentioned footage), a glass cutting machine with a corundum or diamond disk, and a tabletop drilling machine for drilling holes in glass. In addition, it is necessary to have a sharpening machine with a vertical corundum wheel for sharpening tools.

In the calibration room, in addition to fume hoods, all the utensils and reagents needed for marking are stored. According to the requirements, both in the workers and in the utility rooms of the workshop there must be fire-fighting equipment, a box with sand and a dustpan, foam and carbon dioxide fire extinguishers. In addition, do not forget to purchase a first aid kit with dressing materials and medicines to provide first aid to injured workers.

Ready ideas for your business

To organize such a workshop, you will need from 3 million rubles. Payback periods range from 1.5 years. Additional source income (in addition to selling glass products) can come from conducting excursions, master classes and courses for those who want to learn the basics of working with glass.

Industrial production of glass products

Average and large enterprises for the production of glass products carry out full cycle production. The manufacturing process here begins with the preparation of a charge - a mixture of various materials selected in accordance with the type of glass being produced, which is subjected to careful processing. At the next stage, the glass is boiled. This is a very important operation on which quality largely depends. finished products. Glass melting is carried out in special glass melting furnaces with a gradual increase in temperature from 700° to 1450 – 1480 °C. After boiling, the glass mass is cooled slightly, and then products are produced or formed from it using various methods. There are several basic molding methods, including blow molding, compression molding, compression molding and centrifugal casting. Blowing can be carried out by mechanized, vacuum blowing, manual (in molds) and free methods. Separate equipment is used for each of these methods. To produce simple souvenir products, such enterprises use the first two methods. Manual blowing into molds, which is done using a glass blowing tube, is a much more labor-intensive and expensive process, so this method is used here to make complex products. Free blowing (the so-called gutnaya or guten technique) is the free molding of a product (without using a mold). In this case, a glass ball is placed on the tip of the tube, which is then inflated through the tube into a ball with continuous rotation and constant adjustment of the ball with wooden blocks. The resulting workpiece is removed from the tube and placed on an iron rod for further processing. The nature of processing depends on what is planned to be obtained as a result. The master can open the upper part or roll out the lower part of the workpiece to obtain one or another shape. TO distinctive features blown products include a small thickness of the walls of the product, more complex and varied shapes than with other production methods, and high transparency. Centrifugal casting occurs under the influence of centrifugal forces. The press blowing process is carried out in two stages. First, the product is molded in molds, and then it is given its final shape under the influence of hot air. Such products have thicker walls, are not so transparent, but are often decorated with relief patterns.

After molding, regardless of the method used, glass products undergo a firing procedure - kept in ovens at a temperature of 530-580 ° C and slowly cooled. This allows you to significantly increase the thermal and mechanical stability of the material. Then the finished products are processed (the tops that were adjacent to the blowing tube are cut off, the edges, bottom and neck are smoothed using grinding) and decorated with paints and various elements. There are a wide variety of options for decorating glass products. Thus, methods of decorating hot glass (that is, before the finished product cools or even during its production) include tint, satin glass, iridescence, crackle, sulfide glass, glass thread decoration, and colored embankment. Natvet is a decoration made of colored glass that is applied to the surface of colorless glass. Satin glass is a combination of milky and colored glass using complex shapes with ridges and recesses of varying sizes. The sulfide glass technique involves producing marble-like and opalescent strips of different color shades. Colored embankment is multi-colored flows on the background of colorless or colored glass. Iridescence refers to the hot treatment of glass products with vapors of tin or silver salts with the addition of strontium compounds, which form a thin iridescent film on the surface of the material. Crackle decoration involves the formation of thin cracks in colorless or colored glass melt, creating the effect of an antique item (artificial aging). When decorating with glass thread, the finest colored threads and stripes are placed on the surface of the glass melt or inside it in the form of a pattern of arbitrary shape, parallel stripes, spirals, etc.

Finished products are decorated mechanically (for example, engraving), painting, metal films, luster paints, by chemical means(etching), etc. Engraving is a matte pattern with a large number small contour details, which is applied using copper discs of various diameters and abrasive mass. When etching, the pattern is applied using mixtures of hydrofluoric and sulfuric acid solutions, which dissolve the glass. There are several types of etching: simple, pantograph and deep. In the first case, glass products are coated with mastic containing wax or paraffin, then a pattern is applied using special equipment equipped with needles, and then an etching mixture is applied for 15-20 minutes, after which it is washed off with water. This is done mainly for patterns with rings, zigzags and spirals. With pantograph etching, more complex patterns can be made, and thick glass products can be decorated with deep ones. Glass products You can also paint with brushes and a stencil with special silicate paints, followed by firing at a temperature of 550 °C. To create gold ornaments, the metal film decoration technique is used. It consists of applying liquid (twelve percent) or powder gold to clear and colored glass over a frosted and etched relief surface. In this case, gold is applied with a thin brush, then the product is dried and fired to secure the ornament. Glass can also be coated with luster paints and then fired to obtain a shiny metallic film on its surface. Patterned carvings are often applied to glass using grinding wheels followed by polishing, or moldings - liquid glass in the form of droplets and then blowing it to form the desired shape.

There are certain requirements for the quality of glass art products. It must comply with approved reference samples and the requirements of regulatory and technical documentation. Such products are sorted depending on appearance, degree of permissible defects and physical and mechanical properties. In this case, defects in glass melt, production and decoration processing are taken into account. When assessing quality, specialists take into account the type, size, location of the defect and the size of the product itself. Depending on the raw materials used, the type of product and its purpose, glass art products are sorted into grades, the number of which is regulated by standards, and are marked with stickers indicating the manufacturer, trademark, and standard number.

Since glass is a very fragile material, products made from it are carefully packaged in cardboard boxes with preliminary wrapping in soft paper or foam cases. Special requirements are also imposed on the transportation of such products. It is carried out in boxes filled with shavings and other soft materials, with warning notices. But such products do not require special storage conditions in warehouses. It is enough for the room to be dry and closed. Don't make the racks too high. When placing products, consider their weight: heavy products are placed on the lower shelves, and light ones are placed higher.

To organize such production, special expensive equipment will be required: an automated line with a raw material supply channel, “scissors” for cutting molten glass, an automatic press for several molds, a hydraulic press station, a molding machine with an air cooling system, a system for extracting the pressed product from the molding machine, an oven annealing with ejector, paint application unit, drying unit (for drying paint on products), glass crushing and washing equipment, blowing equipment, etc.

The cost of such equipment is several tens of millions of rubles. The exact price depends on the configuration (determined by the product range and planned production volumes), as well as the manufacturer (the most popular is Chinese equipment due to the price-quality ratio). To place the line you will need a large production area– at least 1000 sq. meters. Annealing furnace and drying chamber should be located in a separate room, which, meanwhile, communicates with the workshop. In addition, we need space for a finished product packaging workshop and a separate room for a warehouse. To work in such a production facility, you will need at least 5-7 people plus a foreman-technologist and a supervisor per shift. Most enterprises operate in two or three shifts (with maximum load). Payback periods range from 2.5 years.

Manufacturers of glass souvenir and gift products sell their products through wholesale companies, various retail chains, individual stores (including online stores, although in this case special individual packaging is required for safe transportation), retail outlets and even markets. In general, this product is in consistently high demand, although some seasonal influences are noted. Thus, most orders occur during the pre-holiday periods (before the New Year, March 8). In the summer months, manufacturers of glass souvenirs do not complain about a drop in sales volumes, their “geography” simply shifts. During this period, souvenirs are most actively sold in the south of the country. Many companies even produce special collections with a marine theme for the holiday season.

268 people are studying this business today.

In 30 days, this business was viewed 44,111 times.

Calculator for calculating the profitability of this business

I visited various workshops and factories, saw how jam and metal are made, saw how they catch fish on an industrial scale, and how hemp is tested, and yesterday I visited an amazing place - an art glass workshop. Egor is a master glassblower, he creates wonderful and beautiful things from scratch that anyone can make under his guidance.

1. A complete scam!

Our acquaintance with Yegor began with a small opening remarks masters He told us that he was self-taught, he learned from videos from the Internet, there was no domestic literature on glass as such, so he had to study Western literature. Communication with Russian masters from the Stieglitz Academy, for example, also did not work out, because... Those old guys believe that if they hire him to work or study with them, he will learn all the secrets of the craft from them and run off to create his own company, thereby creating competition for them. As a result, Egor did not fold his arms and go to the West, as many could have done, but having received several practical lessons from an art university teacher, he then began to create with his own hands, creating 3 furnaces and preparing all the necessary base.

2. The base is glass, of course. Egor buys American goods because... There are plenty of flowers, it’s of high quality, but in Russia everything is bad with this raw material, it’s not enough and you can’t get it. Glass is purchased either in the form of similar sheets or plates, or in the form of cubes, which in principle is the same, because everything is melted in the furnace.

3. Furnaces are perhaps the most important component of the process. There should be at least three of them: a glass melting room, in which the temperature is maintained at ~1100 degrees Celsius, a furnace for heating workpieces, and an oven for cooling finished products.

4. All 3 ovens are electric, adjustable with this simple panel. By the way, the workshop is located in the building of the Union of Artists, and it’s cool. In addition to this glass workshop, there are others there.

5. The “cuckoo” stove got its name from the sliding doors that resemble a birdhouse))

6. The temperature there is decent, the oven is used to heat the product during operation. You can’t get inside, it’s hot, but Egor said that he and his friends stuck an action camera in there, wrapped it in cooling rags, and took some cool photos. Fire!

7. Actually, a long blowing tube, with the help of which the whole miracle happens.

8. Liquid glass is taken from the glass melting furnace by a tube and the process of creating a blank for the product begins. In our case, it's a vase!

9. Only a small amount of glass is taken, because V large quantities it's simply not necessary.

10. Then you need to bring the blank along the metal surface to the desired shape.

11. Glass is hot, and that means you can do whatever you want with it, including inflate!

12. Dip the workpiece into the oven again and grab an additional amount liquid glass, it is needed in order to subsequently move to the next oven, in which all the action will take place.

13. Egor moves on to the “Cuckoo”, in which glass is blown and maintained in the required shape.

14. For now, this is just a blank for a vase, that is, transparent glass, onto which a layer of colored glass will later be applied.

15. Blowing continues until it becomes clear that the blank is ready.

16. Then, when the blank is completely ready, you get any colored glass to your own taste, in our case it is a 4-color blank from which the vase will be created. As you can see, our blank is literally stuck to the multi-colored workpiece and is already going into the oven.

17. In order for the blank and the blank to take the desired shape, they need to be united, as it were, by bending the molten glass around the blank.

18. Bent it, now you need to use dental tweezers or any other suitable tool to connect the edges of the workpiece to each other.

19. This is done several times by sending the product into the oven, then bending and joining the edges again, until it becomes clear that the blank and the colored blank are one!

20. Using antique scissors, Egor creates the bottom of the vase, as if squeezing the glass.

21. What next? Then you need to blow and melt for a long time and persistently until you understand that the wall thickness is already required. By the way, as you can see, the stove is on gas. One such cylinder lasts for 1.5 days on average. Due to the fact that the room is small, there is no way to store gas here, so every couple of days you have to refuel at the nearest gas station.

22. Molding is when a product is given the desired shape with wet newspaper. The frozen glass spins around the newspaper, cools, and takes on the required shape.

23. Using some other dental instrument, Yegor applies a pattern to the vase, which we will see soon)

24. Once again, we need to dip our product into a glass melting furnace to apply a layer of glass, to give it gloss, as well as for strength.

25. And again molding. In general, the process is clear and simple - blow, twist, shape, cool. But at the same time, all this is very difficult, and requires care and experience, which you gain by making mistakes and achieving results. As in everything, however. Creative and interesting work, it’s not for nothing that Egor stopped being an office plankton and started working with his hands, that’s cool.

26. Here the product, already with the additional layer of glass that we recently applied, is sent back to the oven.

27. It seems that the master realized that it was time to pull out the product. This is done in a rather cunning way - the tube, with the product at the end, quickly rotates around its axis, making several revolutions, thereby stretching to the desired size.

28. Then, to make the neck of the vase, you need to attach something like this to the bottom (on the left) so that there is something to hold the product by.

29. Meanwhile, on the other hand, the future neck of the vase is created with tongs, as if simply expanding it while the glass is liquid.

30. Go into the oven a few more times, then expand again, and voila, the elegant neck of the vase is ready!

31. The master and his product. In fact, red is yellow, and pale blue is a color closer to blue. When the product cools, it will take on the proper colors.

32. It’s time to cut off that thing from the bottom of the product; we no longer need it.

33. After all, the product is sent to an oven in which the temperature is maintained for a long time at +517 degrees, and then lower, lower, lower, this is necessary so that the glass gradually cools, otherwise it will simply crack and at this point the product will cease to exist. The vase created by us will reach room temperature in 8-9 hours, but we won’t see this)

34. Here, similar to our vase, are already lying on the stove lid. Diverse, beautiful, one might say - each one is unique in its own way. Pay attention to the round things on the bottoms of the vases - these are the remains of those things that were cut off in photo No. 32. In order to remove them, Egor later goes to another workshop, where everything is removed and cleaned by grinding. The vase is ready!

35. Broken pots that were in electric ovens, which became unusable due to the fact that the electricity in the building was cut off and everything was broken.

36. On the shelves are displayed various figures and products that were created here.

37. Cars, for example =)

At the beginning of December, glassblower and owner of the Steklou workshop, Egor Komarovsky, invited everyone who was interested and interested to his master class. The workshop is located on ground floor House of Sculptors of the Union of Artists at the address: St. Petersburg, Zanevsky Prospekt 26, building 2. Egor said that artistic glassblowing is now not as popular and widespread in Russia as in European countries. He mastered the craft on his own, studying literature on English and watching video lessons from foreign masters, he is now open to cooperation, ready to teach and surprise.

All the stoves, and there are four of them, were assembled by Yegor himself in the workshop. An induction crucible furnace can be seen in the center of the photo. It got its name from the Crucible - a container for heating, drying, burning, roasting or melting various materials, in this case it contained molten glass.

In Russia there are about 8 colors of glass on the market, in American markets there are 120, the difference in quantity is quite noticeable. Examples of glasses and their colors.

Let's start the process of making a vase by heating the blowing tube. This is a hollow metal stick 1 - 1.5 m long with a mouthpiece at the end. We were shown the free blowing technique, which involves freely molding a product. Glass objects made by free blowing are also called free-blown glass (from the German hutte - gut, glass-blowing workshop).

Let's scoop up molten glass from the crucible furnace and start blowing it through the tube.

During the cooling process, the craftsman rolls out the cooling glass, correcting its shape.

Let's add more glass from the oven.

The glass ball is getting bigger and bigger.

The sequence at the initial stage is simple: dip, twist and shape, heat, blow...

In addition to free blowing, it is possible to use other techniques: Hand blowing into molds allows you to create products that are similar to one another. For example, laboratory flasks. The glassblower places molten glass on the tip of a glass blowing tube, blows a bubble and begins to shape it, constantly rotating the tube and molding the glass into wooden or metal molds.

Press blowing. The future product is first molded in a mold, and then hot - with air. The products are thicker and less transparent. But this method allows you to create relief decorations on them.

For heating, Yegor uses a “cuckoo” stove. It is heated to operating temperatures from +1100 to +1200 °C. The doors of this oven open if necessary, allowing you to place the product in the oven, rotate it in it, or place the product partially and without contact with the walls.

Gravity helps shape the glass.

A little more time and the ball turns into a drop.

The glass heats up and the tube rotates constantly during heating.

Let's take glass plates of several colors combined into one element, attach it on top of the product and heat it.

After heating, the plate gradually bends and turns around, forming the shape we need when rolled out.

We form the product.

Roll it out again.

And heat the workpiece.

At each stage of work, constant quality and size control is required. When the work is carried out according to the drawn up project, the first version is initially made, which is broken down to accurately measure the wall thicknesses; after making adjustments and amendments, the final version of the product is made.

We heat it up again and blow it out little by little.

After blowing, roll it out into the desired shape.

We create a decorative pattern, pay attention to finished product at him.

We form the ideal shape by gradually rotating and cooling the product. Cooling is done using wet newspaper.

When cooling, the color of the workpiece changes.

Let’s add volume, blow a little more...

Let's add clear glass on top of color. The new layer will be the third, we will get it from the crucible furnace.

Gradually heating and blowing we get a rather large figure of the future vase.

We check the quality.

We form the bottom and secure the product to it.

Create the shape of the neck of the vase.

Last steps...

Annealing is heating to 530–580°C followed by slow cooling. With rapid and uneven cooling after molding, residual stresses arise in the glass, which over time will lead to the product breaking by itself, for no apparent reason. Annealing reduces these residual stresses and makes the glass durable.

After annealing is completed, the vase is polished and can be used for its intended purpose. The annealing oven in the workshop is electric, and when the power is turned off and the glass cools quickly, it becomes fragile and short-lived.

There are many different glass products in the workshop, all of them are made by hand.

If you want to create something yourself, for example, a ball for a Christmas tree, a glass or a vase, or vice versa, you want to learn how to work with glass, then Egor Komarovsky is happy to conduct individual lessons, excursions, and master classes for various age groups.

All details and contacts in the group