Total: 14 units, 2 suppliers, prices from 22,650 to 3,007,315 rubles.

Main aspects of organizing the work of a production workshop semi-finished meat products. Special attention devoted to the selection of equipment used to obtain a different range of this type of product and to the analysis of its characteristics. The presented diagram of the technological process of preparing semi-finished products allows us to better imagine the sequence of its stages.

Purpose

The subject of production is natural large and small pieces (entrecotes, steaks, cutlets, frying, azu, shish kebab), as well as chopped semi-finished meat products (meatballs, meatballs, cutlets, meatballs). Natural semi-finished products are sold for sale in trading network chilled, chopped - frozen.

Raw materials

The main types of raw materials for the production of semi-finished meat products are:

- pork, beef, poultry;

- lard;

- breadcrumbs;

- salt, spices.

Required equipment

Most of the technological operations for the production of semi-finished meat products are mechanized and performed using specially designed equipment, which includes:

- band saw;

- meat grinder;

- mince mixer;

- cutlet forming machine;

- slicer;

- meat ripper;

- packaging machine;

- refrigeration chamber.

Each of the listed types of production equipment has unique functions, advantages and disadvantages that should be taken into account when technically equipping the enterprise.

Band saws for bones and meat

Band saws are machines used for cutting animal carcasses or frozen meat briquettes into portions of a certain size, which greatly simplifies and speeds up further processing of raw materials. Their use guarantees complete preservation of the weight of the product and ensures the receipt of neatly cut pieces, without splinters of bones.

The design features of the strip slabs allow you to adjust the height and thickness of the cut. All parts in contact with the product are made of stainless steel, and are easy to use and safe.

There are many models of band saws from different manufacturers on the market. The cost of the proposed equipment ranges from 45 to 270 thousand rubles. and largely depends on its productivity, which in most models is 300-500 kg/h. For small businesses, taking into account their capacity optimal solution The choice of saws will be from the Russian companies MM PRIS, RostPischMash.

More expensive models from SIRMAN (Italy) or Mainca (Spain) are an excellent option for large food production.

Meat grinders are designed for grinding meat

The machines are equipped with a set of replaceable knife grids with different hole diameters. By installing the appropriate set of them, the degree of grinding of raw materials is regulated: for example, minced meat for natural chopped semi-finished products should consist of larger pieces. Equipment of this type is available in floor-standing and table-top versions and has devices that ensure safe operation.

The minimum cost of industrial meat grinders is about 10 thousand rubles. Its upper limits are not limited - individual companies sell cars at a price of 400 thousand rubles. When choosing a model for a small enterprise, you should first of all be guided by the planned quantity of products. The best option is traditional MIM meat grinders, producing from 80 kg of minced meat per hour, produced by the Belarusian company Torgmash.

Powerful meat grinders model KT LM with a capacity of up to 1150 kg/h from Koneteollisuus (Finland) are suitable for large-scale production.

Meat mixers

To obtain a uniform consistency, all products included in the minced meat are mixed using minced meat mixers. During this process, the mass is saturated with oxygen from the air, becomes fluffy, and the products prepared from it after heat treatment become juicy and appetizing. The recommended duration of mixing one portion is 60 seconds; with a longer process, the fat begins to separate from the meat and stick to the inner walls of the machine, which deteriorates the quality finished products, makes them dry.

The cost of minced meat mixers is in the range of 50-300 thousand rubles. Like other equipment, it is directly related to the performance of the machine. For small businesses, the widest range of models with a working chamber volume of 50 liters or more is presented by RostPishchMash.

Foreign manufacturers, for example, the Italian companies La Minerva and SIRMAN, offer equipment that is more powerful and expensive, aimed at use in large food production facilities.

Cutlet forming machines

Cutlet forming machines are necessary for giving shape to products. Some models have a replaceable molding table with holes of different configurations, which makes it possible to alternately prepare several types of semi-finished products, for example, cutlets and meatballs. This type of equipment has high productivity and allows you to produce products of a given weight and size.

The cost of cutlet-forming machines depends on the number of attached replaceable dies and productivity and ranges from 24-450 thousand rubles. The most expensive and highly productive (up to 2500 pcs/h) - from Gaser - are intended for large-scale production.

Their Russian analogue, RostPishchMash, with a productivity of 2000 pieces/hour, is more affordable in price and ideal for small businesses.

Slicing machines

Slicing machines are used to produce natural portioned and small-sized semi-finished products. They are characterized by high productivity and provide products that have a neat shape and the same weight. Meat can be cut frozen, chilled or fresh, while the quality of its processing remains consistently high and the percentage of waste is minimal.

Portion cutting machines have a high cost: from 700 to 1500 thousand rubles. They are not produced by Russian manufacturers, but the most famous foreign one is the German company Treif Maschinenbau GmbH, which offers models of various capacities, from 180 to 400 cuts/min, among which you can choose a machine for both small and large enterprises.

Meat rippers

Meat rippers are used for loosening portioned pieces of meat intended for frying, as well as for “stitching” them. Using special knives, cuts are made on the surface of the product on both sides so that during cooking the piece of meat is not deformed and the finished dish is soft and juicy. At its core, the loosening operation is a mechanized analogue of beating. This type of equipment is equipped with safety systems to ensure safe operation.

Meat rippers presented on the equipment market have different productivity (from 1000 to 2500 pcs/hour) and cost (from 30 to 180 thousand rubles), which are directly dependent. For small businesses, machines produced by OMAS (Italy) are an excellent option, offering optimal price-quality ratio.

Prepared semi-finished products are packaged and packed in trays. For this purpose, automatic or semi-automatic tray sealers are used to ensure the tightness of the packaging, thereby significantly increasing the shelf life of the products.

Package

Tray sealers have different levels of productivity and automation and make it possible to simultaneously pack from 1 to 4 trays of semi-finished products. The cost of such equipment is in the range of 150-1000 thousand rubles. For small businesses, semi-automatic machines are an excellent option. Russian company CAS, which are not inferior in their characteristics to foreign analogues.

Storage

Used for storing semi-finished products before sale. refrigeration equipment– chambers or cabinets, preferably combined or low-temperature ones. For small businesses, it is advisable to purchase 2 chambers: for storing refrigerated and frozen products. These can be both chambers with a combined mode or, one each, with low temperature and medium temperature. Recommended internal volume – from 10 m3.

Technological cycle

Technological cycle of production of semi-finished meat products

Technological cycle of production of semi-finished meat products

Premises and communications

A workshop for the production of semi-finished meat products must meet the following requirements:

Requirements for premises and communication systems of production workshops are set out in various forms regulatory documentation: SNiP, SanPiN, etc. Compliance with them guarantees the production of products that are safe for consumer health and minimizes the risk of contamination with pathogenic bacteria that can cause food poisoning.

The demand for fresh meat products is constantly growing. The main competition is between the chilled and frozen segments. There is still a place in this niche for everyone, because different types of semi-finished products are clearly differentiated by purpose and distribution channels.

The volume of meat consumption in Russia has been constantly increasing over the past 10 years. Even based on the results of the depressed year 2015, there is an increase (3%) compared to the previous period. At the same time, the production of semi-finished products is growing most actively, as well as their consumption. This is explained by the employment of the population, accelerated dynamics modern life. To understand whether this area is promising for small businesses, let us briefly describe:

- features of the Russian meat products market;

- types of products, preferences, sales network;

- technologies and equipment for meat processing;

- regulatory regulation of this type of business.

Supply and demand for semi-finished products

About 50% of the total volume of meat (Russian and imported) is sold raw. Approximately 30% goes to sausage products, 5% to canned food, about 15% to the production of semi-finished meat products and supplemented with other ingredients. In recent years, their consumption has increased by 10-15% annually, while sausages have increased by only 5% (Fig. 1).

Figure 1. Dynamics of growth in the production of semi-finished meat products according to Rosstat.

Almost tenfold growth is a response to constantly growing demand. But production is distributed unevenly across regions (Fig. 2). Traditionally, over 60% falls on the Central and Northwestern districts, where large meat processing plants are concentrated. According to experts, consumption of these products will grow in the next 3 years, with the highest rates expected in the periphery.

Figure 2. Structure of distribution of meat processing enterprises by district in 2013.

Increased demand has changed the strategy of large meat holdings (Fig. 3). If earlier they focused on the production of sausages, frankfurters, and other delicacies, then in the last two years they have been actively repurposing them into raw semi-finished products. This will certainly lead to increased competition. Developed capacities of giant enterprises, own raw material base, possibility of acquisition imported equipment and new technologies puts small businesses in obviously unfavorable conditions.

Figure 3. Zones of influence of Russian agricultural holdings for the production and processing of meat in the European part of Russia. According to Kommersant.

Most large meat processing plants produce frozen products. Transition from sausage production to products for culinary processing, the purchase of new technologies increases its cost. Standard packaging is also inconvenient: small ones are expensive for the manufacturer, large ones are not suitable for the buyer. Bulk goods are now in high demand.

Small businesses find a place in this niche for several reasons. Proximity to sales points provides savings transport costs. And price in times of crisis is the main regulator consumer demand. In addition, consumers are increasingly choosing chilled meat rather than frozen meat; even if its cost is 10 - 15% higher. Since the shelf life of such products is up to 7 days, retailers buy them from local producers. However, they often complain about the poor assortment and low quality of the goods.

Types of products, sales directions

Semi-finished meat products are produced from all types of meat: beef, pork, poultry, including offal. Currently, their range includes about 40 units. Products are usually divided into two large categories: chilled and frozen. According to manufacturing technology, they are:

- Natural. Large, small-piece products, mainly from chilled meat: oven-baked beef and pork, steaks, natural cutlets, shish kebab, stew, soup sets.

- Breaded. Ready-to-cook dishes from fresh and defrosted meat in liquid (with egg) breadcrumbs: offal, chops, rump steaks.

- Chopped. Products made from low-grade raw materials, often with the addition of bread and spices: cutlets, steaks, meatballs. This group also includes packaged and loose minced meat.

Mixed semi-finished products with the addition of dough and, to a lesser extent, vegetables are widespread on the Russian market (Fig. 4). The undisputed leader is dumplings; they even came up with a special vending machine for them.

Figure 4. Indicators of consumption of fast food products by type (2014).

Product sales channels:

- Networks retail - their share is about 50%. Dumplings and cutlets sell well in retail outlets all kinds. Sliced meats (kebabs, goulash), minced meat, pancakes, pasties, manti - prevail in markets and supermarkets. Both frozen and chilled products are sold.

- Specialty cookeries- occupy approximately 10%. This regular stores selling goods from the counter. Our own culinary workshops allow us to prepare a diverse range of ready-made dishes, quickly responding to seasonal changes, changing tastes and needs. They sell finely chopped meat in marinades, kebabs, goulash, khinkali, cabbage rolls.

- HoReCa segment- About 14% of semi-finished meat products are sold through it. It is developing the fastest thanks to the spread of fast food. Buyers - restaurants, bars, canteens, fast food cafes. Frozen products are often supplied to catering establishments; large high-tech production benefits here.

Main trends for 2016 – 2019:

- Increased demand for chilled products; increasing the share of poultry meat: chicken and turkey.

- Expanding the range of dishes in sauces, marinades of original recipes; with the addition of vegetable ingredients.

- Displacement of traditional products by new, original dishes of the national cuisine of the peoples of the world.

- Increased consumption of semi-finished products in the expensive segment, ready-to-eat meals.

If an entrepreneur decides to open meat business, first you need:

- determine which market segment to work in, select an assortment;

- find, master, develop recipes taking into account modern technologies;

- purchase professional equipment, transport for delivery.

The technological process, for example, for natural semi-finished products includes:

- defrosting of carcasses, half-carcasses (defrosting) in the amount of daily processing - if necessary, if the workshop is located separately from the slaughter place;

- washing, drying, cutting into large cuts, trimming, trimming;

- preparation of portioned, small-piece, chopped products using special machines;

- packing goods into functional containers, sealed bags, labeling;

- cooling (freezing), storage, transportation to a warehouse.

As for the recipe, buyers prefer semi-finished meat products with a minimal degree of processing. For example, if these are chickens, then they are simply cut into half carcasses, breasts, wings, etc. However, there is a growing demand for “convenient” products, balanced in composition, with different ingredients, allowing you to prepare a dish using quick culinary methods. For this purpose, modern packaging such as “protective atmosphere”, “ gas environment" Experts believe that owning them will soon become a ticket to the natural chilled food segment.

Inexpensive equipment for all types of processing is produced Russian factories. It can be selected individually, or you can purchase a ready-made modular workshop for the production of semi-finished products. The selection depends on the future assortment. As a rule, the equipment of the workshop is formed by: band saws, cutting presses, meat grinders of various capacities, machines for applying breading mixture, cutlet or dumpling machines. If there is no work experience, it is advisable to find a supplier who provides comprehensive services, including training, information support. Often such equipment is purchased on lease. The main selection criteria: an integrated approach (multifunctional lines) and rationality - the ability to ensure the sale of the entire volume of manufactured products.

Organizational and legal issues

Production of meat, others food products with it (semi-finished products, canned food, sausages); rules of storage, transportation, packaging, labeling are regulated Technical Regulations TS “On the safety of meat and meat products” (TR TS 034/2013). This document contains all the requirements, manufacturing conditions and classification of products with different meat contents, for example:

- meat - (> 60%) with the addition of other ingredients;

- meat-containing - (5 – 60%), including flour, eggs, cereals, water;

- meat and vegetable - (30 – 60%) using plant components.

Only the main groups are listed, in fact there are many more. After the development of the relevant GOSTs, their names will be indicated during labeling. In accordance with the Regulations, manufacturers are required to issue one of three documents:

- veterinary certificate- fresh unprocessed meat (veterinary organization of the Ministry of Agriculture);

- state registration certificate- meat products for baby food (Rospotrebnadzor);

- declaration of conformity(DoS) - processed meat, including semi-finished products (certification body).

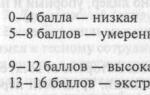

Declaration is carried out according to three schemes: for the period of storage, 3 and 5 years (Fig. 5). An accredited laboratory of the Customs Union has the right to conduct tests, draw up and register DoS.

Figure 5. List of actions to obtain a declaration of conformity for 3 years.

Each manufacturer must have a package of documents, including technical documentation, laboratory test reports and DoS. As for the sale of meat products, it does not have any special differences and is regulated general rules for retail trade.

To sum it up. For small enterprises, the production of finished products is unprofitable, since it is difficult for them to compete in terms of quality with sausages and sausages from large meat processing plants. It is more practical to produce fresh products that do not require deep processing of meat and do not duplicate common well-known brands. It is cheaper, does not require mastering complex processes or attracting qualified specialists.

Most people find less and less time to cook their own food. In the modern world of constant rush and development of new technologies, it would be wrong not to take advantage of this fact. Therefore, a workshop for the production of semi-finished meat products seems a very tempting idea. Of course, it is much easier to start such a business with a ready-made business plan, examples of which you can find, and, if desired, buy in our catalog. Let's try to figure out how profitable and justified it can be.

Types of semi-finished products

The name “semi-finished product” itself implies a product that is already half ready; the consumer can only carry out the final stage of the technological process - preparation.

According to experts, this market segment is expected to grow increasingly in the coming years. Products of this kind can be classified according to several criteria:

- by processing method: chopped and natural;

- by type of meat used in the cooking process: pork, beef, chicken, rabbit, lamb, mixed;

- by thermal state: frozen, chilled.

In addition, all products can be divided into natural and processed:

- natural – chopped, large-piece, meat-and-bone, portioned, small-piece, pickled and other sets;

- processed - cutlets, meatballs, meatballs and other products made from processed minced meat.

A separate group includes dumplings, khinkali, and pancakes.

Permits

If the question of how to open a workshop for the production of semi-finished products has seriously interested you, then it should be recalled that this type of activity involves contact with food, and therefore you should start by obtaining all the necessary permits to open such an enterprise. Our business plan, which you can view and purchase via the link, will help you not forget anything and adhere to the right actions.

The first step is business registration. The best form in this case would be an LLC, since, as practice shows, it is much easier to sell products as a legal entity. After this, you need to register with the tax authority and obtain a taxpayer certificate.

Certification

The next stage is product certification. Here you will need:

- permission from the SES;

- your production control program;

- permission from Rospotrebnadzor;

- certificates for all types of products.

All workshop employees must have health certificates. You also need to attach to the package of documents permission from the fire department to carry out this type of work in a specific premises and a lease agreement for the building.

Selecting a location for production

Let’s immediately rule out the options for premises in which it is simply impossible to locate such production:

As for the space occupied, in order to open a workshop for the production of semi-finished products, which will provide a ton of products per shift, you will need 20 square meters. In addition to the workshop itself, the building must have rooms intended for personnel, showers and toilets, as well as a warehouse for storage finished products and raw materials.

A good location option would be an area near farms who are engaged in breeding animals. They can become your suppliers, and you can save on transportation costs.

Staff

It is necessary to select personnel to maintain the workshop. You should immediately take into account that at least three people will be needed to work with the installation on one shift. In addition, you should hire the following specialists:

At the first stage, when your company is just opening, you may not need some employees from this list yet, since one person will be able to combine several functions. But ideally, the staff should look like this.

Equipment

The largest cost item for opening a manufacturing plant is always purchasing necessary equipment. For this direction, this stage is the most important, since the speed and volume of production will depend on the quality and quantity of tools and machines.

So, equipment for the production of semi-finished meat products should include:

If your plans also include the production of dumplings, then you will additionally need a flour sifter, a dumpling machine, and a dough mixer.

Production process

Even if you are going to cook semi-finished meat products according to your own recipes, it looks production process itself is about the same.

To prepare minced meat products, the shoulder, neck, and thigh muscles, which contain more rigid connective tissue, are most often used. To begin with, the meat is ground, then eggs, spices, and fat are added to it. The minced meat is then passed through a grinder. Next, pork lard, water, and salt are added to it. Then all this mass is kneaded in a minced meat mixer and loaded into a hopper to form cutlets, meatballs and other products.

It is in this installation that the product acquires the specified shape and specified weight. From there, the cutlets go onto a conveyor, which delivers them for breading. Then the cutlets are placed in carts and sent to a blast freezing chamber; this process takes approximately 2 hours. Finally, the finished products are sent for packaging and storage in low-temperature refrigeration chambers.

Counting expenses

To get an overall picture, you can’t do without a preliminary calculation of expenses.

So, at the initial stage you will need:

Don’t forget about employee salaries and utility bills that you will have to deal with after just a month of work.

On average, we can say that to open a workshop you will need at least 5 million rubles. If the quality of the products meets consumer expectations, and you are able to provide sales markets, then the payback period will take about a year.

High quality business plan

This article widely covers the idea of starting the production of semi-finished products yourself, but in any case, when starting out, you will need quality business plan, you can familiarize yourself with and purchase a ready-made one using the link.

Production of semi-finished products: Video

Semi-finished meat products, also called minced meat, are very popular among consumers. Semi-finished products, which take just a few minutes to prepare, are an excellent alternative to “full” meals. Semi-finished meat products also have certain advantages in production: they help facilitate and simplify the work of procurement shops, reduce the time required to prepare a meat dish or snack, and allow you to increase throughput enterprises.

According to statistics, the production and consumption of meat and meat-based products in our country is increasing every year. This market is projected to grow by 10% annually over the next few years. Moreover, experts note the highest growth rates in the segment of chilled semi-finished meat products. Approximately 45% of the total volume of meat produced in our country or brought from abroad is sold raw. About 30% is used for the preparation of sausages, about 20% is used for the preparation of semi-finished products and the remaining 5% is used for the production of canned food. The sausage market has hardly been growing over the past few years, but the segment of semi-finished meat products has been steadily increasing its share by 10-15% every year. This is due to the fact that consumers are switching from frozen meat products to chilled ones (primarily, this applies to the segment of chilled meat, poultry and semi-finished products).

So, what exactly products are classified as semi-finished meat products? Minced semi-finished meat products are a portioned product that is made from chopped raw meat (minced meat) with various additives. As a rule, such products are classified according to the processing method. There are natural, chopped semi-finished products, dumplings. There is also a common classification according to the type of meat used - beef, pork, lamb, poultry, rabbit; according to thermal state - chilled and frozen. Experts also divide the market for refrigerated semi-finished products into two separate segments – natural and processed products. In turn, the first segment is divided into several subgroups: large-piece, meat-and-bone, chopped, small-piece, portioned, marinated, meat sets (for example, soup, for barbecue), etc. Processed semi-finished products include cutlet products (this group includes different types of cutlets , meatballs, meatballs and other processed meat and minced meat products). The main raw materials for the preparation of chopped semi-finished products are the cervical, scapular and femoral muscles, which contain coarser and tougher connective tissue. The meat is thoroughly minced using special equipment, and then fat, spices and eggs are added to the finished minced meat. Let's look at the cooking technology in more detail. First, frozen raw meat in the form of blocks is crushed in a crusher. Sometimes mechanically separated meat is used to prepare minced meat, which is prepared in a meat and bone separator. After grinding, the minced meat is passed through a grinder. Then, pre-ground pork fat, salt, pre-chilled water, spices and other additives are added to it. The whole mass is thoroughly mixed using a mince mixer or using a cutter. The cutter is designed for grinding thin soft meat raw materials and turning it into a homogeneous mass.

The finished minced meat is loaded into the hopper of the machine for molding semi-finished products. It is here that the product is given the required shape with a certain weight for each portion. For this, depending on production volumes, a screw or rotary product molding system is used. In the forming machine, the cutlets are given a given shape, after which the semi-finished products are laid out on a conveyor belt. Then, depending on the recipe, the product is sent either to a frosting machine and then (or immediately) to a breading machine for liquid and dry breading. Finally, the finished semi-finished products are placed in trolleys and transported to a blast freezing chamber or fed automatically via a conveyor to a spiral freezer.

The duration of freezing may vary. For example, the duration of freezing a cutlet weighing 85 grams in a blast freezing chamber is two hours, and in a spiral freezer this time is reduced to 45 minutes. At the last stage, semi-finished products are packaged in plastic bags and cardboard boxes, and then moved to a low-temperature refrigeration chamber.

Recipes for preparing various semi-finished products vary depending on the type of product. For example, Moscow cutlets are made from beef meat with the addition of raw lard and wheat bread, onions, pepper, salt and water. The prepared minced meat is given an oval-flattened shape. Pozharsky pork cutlets are prepared from lean pork with the addition of pork melange, wheat bread, salt, pepper and water. Sometimes onions are also added there. Amateur cutlets are made from beef carcass meat with fatty, above medium and medium fat content.

The pre-prepared pulp is crushed, mixed with spices, wheat bread and other ingredients, and then a large cutlet is formed from it, which is then breaded in ground breadcrumbs. To prepare Kyiv cutlets, pork with a fat content of no more than 30% is used. Beef schnitzel is made from minced beef meat, which is shaped like a flat oval cake. Meatballs, which are prepared using the same technology as Moscow cutlets, are shaped into balls. To make zraz, minced beef stuffed with hard-boiled chopped eggs mixed with fried onions and ground breadcrumbs is used. A rump steak is a lightly pounded piece of meat weighing about 115 grams, which is cut from the thick end or sirloin, moistened with a beaten mixture of fresh eggs, water and salt. Beefsteak is a type of steak made from the head of the tenderloin. Chopped steak is similar in cooking technology to a cutlet. Quenelles are balls of minced meat, chicken or fish with the addition of cream and eggs. Bits are small round cutlets made from minced meat, and meatballs - balls of minced meat or fish with the addition of finely chopped onions, herbs and spices. Kufta is a national dish similar to meatballs, but made from lamb. Frozen semi-finished meat products also include dumplings, which are made from dough filled with minced meat from a mixture of beef and pork in an amount of 55-57% of the weight of the dumplings with the addition of eggs, onions, pepper, salt, and sugar.

The main raw materials for the production of semi-finished products are beef, pork, poultry and fish, and less often lamb and horse meat. Twice frozen meat and pork with darkened lard are not allowed to be used. Protein preparations of plant and animal origin (soy products, milk proteins, etc.), melange, egg powder, vegetables and other components are also used.

For organization own production semi-finished meat products, first of all, you need to draw up a detailed business plan. When making calculations and making forecasts, you cannot do without marketing research data. You will also have to carefully study the market for raw materials, the sales market, and the offers of equipment suppliers. After analyzing and comparing the prices and characteristics of various equipment, you can choose one or more suppliers. In addition, you will need to carry out large-scale work on the selection of regulatory and technical documentation that exists for meat food products, or develop your own technical specifications for semi-finished meat products if you plan to produce products according to unique recipes. Don’t forget to coordinate all the details with the SES and go through the certification procedure. However, some equipment suppliers are ready, for an additional fee, not only to equip your meat processing plant, but also to advise you on the main issues that you may have during your work.

However, before contacting companies that sell equipment, consult with specialists. This way you can protect yourself from unnecessary expenses. A meat processing or culinary shop, depending on the planned range of products, must be equipped with the following equipment: cutting presses and band saws for preparing meat, meat grinders for chopping, slicers for cutting semi-finished products, dumpling and cutlet units for molding semi-finished meat products, and packaging machines. In addition, if you are also going to produce, for example, dumplings, you will need flour sifters, dough mixers for hard dough, and a dumpling machine. You can’t do without a freezing chamber, storage chambers for raw materials and finished products (they must be separate), a lezoning machine, scales, production tables, a minced meat mixer, a meat grinder, a cutlet machine, a universal kitchen machine, a washing bath, cutting boards and knives, bactericidal lamps for disinfecting work surfaces. The meat processing shop, with a capacity of about 1000 kg of products per shift, occupies an area of about 16 square meters. meters. Power consumption is 12.47 kW. Experienced manufacturers advise locating workshops close to farms and peasant farms, which will significantly reduce transportation and other costs.

However, if you are not going to also organize a workshop for slaughtering cattle, which, on the one hand, helps solve the problem of supplying raw materials and increases profitability, and on the other hand, will require large investments, you can open an independent enterprise for the production of semi-finished meat products. But in the latter case, you will have to make a lot of effort to find suppliers of inexpensive and at the same time high-quality raw materials. After all, the quality of your products and the reputation of your company will directly depend on the quality of the latter.

Basements where there is no or limited space are not suitable for organizing a meat processing workshop. natural light, premises in residential buildings or next to residential premises, premises with limited installation capacity, premises where the introduction of gas networks is excluded, with a limited ceiling height (recommended ceiling height is more than three meters). Also, you should not consider rooms with complex architectural and planning solutions, rooms where it is impossible to join existing flow-exhaust ventilation networks, where interconnections are excluded separate groups production premises with recycling food waste(containers for waste collection should be placed at a distance of no more than 25 meters from the building where production is carried out).

To service equipment in a small enterprise, two or three people per shift are enough. In addition to workers in production, staffing table your enterprise will include a director management company, production director, financial manager, logistics, accountant, chef, chief technologist, quality inspector, HR specialist, IT engineer, cleaners, raw material purchasing managers, finished product sales managers.

As is known, the technology for preparing semi-finished meat products consists of a number of operations (cutting carcasses, boning and trimming meat, mechanical and refrigeration processes). At each of these stages, quality control must be carried out. For example, for the production of semi-finished products, you cannot use raw materials of questionable freshness, with the presence of contamination, injuries, bruises, or darkening of certain areas muscle tissue. The quality of carcass cutting is checked by a foreman, a technologist and an inspector. The separation of muscle and fat tissue from bones (boning) is carried out in a room with an air temperature of no more than 12°C. When separating tendons, fat, and blood vessels from meat, all waste is immediately removed from the workshop, and the trimmed meat itself is immediately sent for further processing and cooling.

The temperature of finished semi-finished products must be maintained at less than 8°C. To increase the duration of their storage and maintain quality, special packaging is used - vacuum, hermetic, packaging and placing in a bag with subsequent sealing, wrapping in polymer film. The packaging of such products must be sealed, durable, transparent and colorless. In this case, it must be applied to its surface necessary information about the product.

The profitability of a workshop for the production of semi-finished meat products is about 30%. However, many manufacturers manage to increase the profitability of their enterprise by up to 80% by changing the recipe (introducing various ingredients that reduce the amount of minced meat in the product) and/or by saving on raw materials. Both options are unlikely to be suitable if you are planning long-term work and care about the reputation of your company.

Lily

Sysoeva

- portal of business plans and manuals