The club of countries that own fifth generation aircraft has arrived. Along with American and Russian aircraft. Great hopes are placed on the newly introduced J-20 fighter, because, in essence, this aircraft is business card The Chinese Air Force and the entire Chinese defense industry. From borrowing to own school At the Airshow China 2016 aerospace show in Zhuhai, which started on November 1, China presented the J-20 fifth-generation fighter to the public. And although rumors, speculation and analysis of data on this fighter were published in the press and specialized publications for many years, demonstration flights of the J-20 proved the main thing: work on creating a domestic fifth-generation aircraft in China never stopped. Even despite the fact that the creation of its own a modern fighter is an extremely difficult and costly task; the Chinese military and industrialists, along with the modernization of existing aircraft, decided to focus on creating a high-quality new product. Nevertheless, the choice in favor of a new one does not mean at all that Chinese aviation engineers have decided to abandon already developed and implemented technologies. However, the concept of using well-developed fourth-generation solutions, which Chinese engineers are trying to combine with the requirements for fifth-generation aircraft, reveals a whole bunch of problems. These include the creation and development of software and hardware for the operation of on-board systems, the integration of the fighter as a combat unit into the control system, as well as the creation of its own engines, protective equipment and weapons. Experience and problems Despite the fact that the lack of a completely domestic fighter developed practically from scratch has long been a subject of debate among the Chinese military and specialists, the PRC decided to create its own fifth-generation fighter with an eye to the past. It's no secret that China often copied foreign military equipment and adapted the best ready-made solution to suit my own needs. Examples of this approach are the J-11 fighter, which is an almost exact copy of the Su-27, and the J-15 carrier-based fighter. However, to create a fifth-generation fighter operating at other speeds, altitudes and in other modes, simple copying is already ready-made solutions and their modifications were no longer suitable. However, the Chinese military-industrial complex, when creating a fifth-generation fighter, used an unusual technique, which included the implementation of already tested solutions and the development of new ones at the same time. Considering that no country in the world would share promising military technologies for free and of their own free will, Chinese engineers decided to create own fighter, using technological solutions from all implemented projects in this area simultaneously. The main difficulty for the Chinese military-industrial complex, whose aviation specialists have never been at the pinnacle of the art of building aircraft, was the process of combining different design solutions and schemes. For example, the aircraft was based on a glider made according to the canard aerodynamic design. Previously, the promising multifunctional fighter MiG MFI was created using the same design. And although the prototype MiG MFI was designed to reduce radar signature and increase maneuverability, the Chinese aircraft has a number of key elements that, on the contrary, increase the “lighting” of the J-20 on the radar observation screens and complicate its control at extreme conditions. “Despite this. that the design used in the glider is quite original, it is believed that the very use of such aerodynamic design significantly increases radar signature. It is also worth noting that not a single foreign fighter with such a design is used,” military expert Vasily Kashin analyzes the history of the creation of the J-20. If we omit the borrowing of a configuration that is not the most successful for a fifth-generation fighter and how it is implemented in a Chinese fighter, then you can find that individual components and assemblies are also either built taking into account already proven technologies, or are not designed by engineers in the most successful way. The design of the large all-moving front horizontal tail noticeably increases radar signature and air resistance, affecting the flight range. Individual components of the aircraft, such as air intakes, glazing and the cockpit “canopy” itself, as well as the nose, are strongly reminiscent of the American promising fifth-generation fighter F-35 . In addition, the layout of the J-20 is influenced by the American F-22 fighter: the huge air intakes are located at almost the same angle. Military observer Viktor Baranets is also confident that engineers from the Middle Kingdom collected parts and assemblies for their fighter from all over the world. “Copying other people’s products is national tradition China. The Chinese present this car as a sensation; foreign experts give a calm assessment of this product. I'm almost sure that tactical and technical characteristics this vehicle lags behind both its American and Russian counterparts,” the military observer concluded. Russian« heart"Despite the fact that Chinese aircraft manufacturers are rather on the first rung of the ladder leading to the possession of a fifth-generation fighter, their main task engine builders from the Middle Kingdom have not yet decided. In the several years since the start of development, they have not been able to build a full-fledged aircraft engine for such an aircraft, and demonstration flights of the J-20 took place thanks to the installation of Russian AL-31FN engines into the fighter. In addition, many questions remain regarding avionics. “The situation with AFAR for radars is still quite unclear. They have it, but what its performance and characteristics are is unknown. Therefore, it is too early to say that it is fully operational and effective,” a military expert noted in an interview with the Zvezda TV channel. editor-in-chief magazine "Arms Export" Andrey Frolov. Considering that a modern engine and an effective radar for a fifth-generation fighter are the same as the heart and eyes for a person, we can conclude that the Chinese J-20 will be able to fly in the near future only with a Russian “heart”. As for our own fifth-generation WS-15 engine, it is still not ready, and, despite the great interest and desire to create our own “heart” for the fighter, there has been no breakthrough in this direction at all. at the moment not expected. Experts indicate that the previous self-developed WS-10A engine, which a number of experts proposed for the Chinese fifth generation, cannot be used for mass use in such fighters. Theoretically, the problem could be solved by another proprietary development - the WS-10G engine with increased thrust performance. However, experts explain that the reliability and service life of this engine leave much to be desired and cannot be used in a serial fighter. Despite this, the Chinese Shenyang Aircraft Corporation, almost simultaneously with the J-20, is creating the fifth-generation multirole fighter J-31. This machine is significantly lighter than the J-20, but just like its heavier “brother”, it flies on Russian RD-93 engines. Using motors Russian production, as well as the extensive introduction of composites and other lightweight aviation materials allow the J-31 to “saddle” a combat radius of 1250 kilometers and reach a speed of about 1.6 Mach. In the future, it is planned to replace Russian engines to domestic WS-13A, however with practical implementation Great difficulties arose with this idea in the PRC. And although the country's authorities are confident that the J-20 and J-31 will help reduce the gap with US aircraft, Chinese fifth-generation fighters in almost all respects key indicators(thrust-to-weight ratio, maneuverability, stealth) also lag behind Russian fighters Su-30, Su-35, T-50, and from the American F-22. Among other things, the big questions are placement, composition and quality. missile weapons these aircraft. According to experts, the fifth generation will definitely need modified short-, medium- and long-range missiles, and the PRC will also have to work seriously in this direction. If Chinese aircraft manufacturers bring the story with the J-20 and J-31 to serial production and create their own (or enter into a strategic agreement on the supply of Russian) engines, then Chinese fifth-generation fighters can be fully compared with competitors in terms of the totality of qualities, including the cost of the entire program and the production of each aircraft. Strategic insurance Due to the fact that when implementing the program to create and produce their own fifth-generation fighters, Chinese aircraft manufacturers encountered serious difficulties, the PRC authorities, in their characteristic manner, decided to hedge their bets both for their own peace of mind and for the sake of national security signed a contract with Russia for the supply of ultra-modern Su-35 fighters. It is the delivery of the Su-35 that will allow China to close the gap with the United States and increase the efficiency of its own aviation in the turbulent Pacific region. “American experience with the F-22 and F-35 fighters shows that years pass from the moment these aircraft enter the military until they reach combat readiness. Therefore, the main combat force of the Air Force and naval aviation in the medium term, there will still be 4++ generation aircraft, including on the T-10 platform (that is, derivatives of the Su-27),” explains Vasily Kashin. The purchase of Su-35 fighters will also allow the PLA Air Force to get the most out of its own aircraft and, if necessary, repel an attack... by American F/A-18 carrier-based fighters, because from the point of view of technical capabilities, Chinese aircraft can provide the most fierce resistance to American carrier-based fighters. “With the Chinese J-10B, J-11B, J-16, you can safely go into battle against the F/A-18E/F Super Hornet and win. The whole question is to bring tactics and combat training up to the American level,” adds Kashin. The expert’s statements confirm the long-standing assertion of aviation experts that direct confrontation with fifth-generation aircraft has not yet begun and all the work in the sky in the next few years will be performed by generation fighters 4++. However, China’s desire to create its own “five” as soon as possible is quite logical: the openly unfriendly behavior of the US Armed Forces “on the threshold of its own home” makes it necessary to play it safe and, just in case, create effective and relatively inexpensive countermeasures. In this context, the creation of a fifth-generation fighter with a combat radius of two thousand kilometers looks like a task that is fully in line with China’s national security interests. Regarding expert assessments, then aviation experts believe that the fate of the Chinese J-20 and J-31 fighters will be difficult and long. J-20 to achieve the specified technological level should be lighter and more maneuverable, and without major changes in the design of the airframe and its own productive engine, it will be extremely difficult to achieve high speed performance instead of those obtained in practice. It is extremely difficult to talk about the export potential of both machines, as well as how well they correspond to the characteristics of a fifth-generation fighter difficult. The main difficulty Chinese engineers are lacking their own aviation design school and research experience, and the decision to assemble “a little bit from each fighter” risks the fact that such a machine may not be suitable for performing the assigned tasks at all. Looking at the J-20 and J-31, one can judge that the PRC has not yet found its own style and direction in the creation of aviation technology, which means that Chinese aircraft manufacturers have many years of painstaking work ahead of them. In fact, the Chinese military-industrial complex is ahead awaiting dozens of development projects on the use of aviation materials, calculations of the most optimal airframe configuration, elaboration of issues of reducing radar signature and, to top it all, the creation of our own aircraft engines. Only if all conditions are met will Chinese fighters stand on a par with Russian and American fifth-generation aircraft and begin to perform the tasks for which they are created.

The Achilles heel of the Chinese aircraft industry is engine manufacturing. This is known to everyone whose occupation is associated with the production of aircraft. Of course, Chinese specialists themselves are most familiar with this problem.

Both the Chinese military and the aircraft manufacturers themselves refuse to equip their equipment with their own engines, since they are more satisfied with Western and Russian developments. But Beijing is seeking to reduce the share of imported power plants in its air fleet.

In one fist

Probably, the significance of the problem has reached such an extent that it has been taken up at the government level. In China, a decision has been made to reform the industry - to separate engine specialists from airframe developers and manufacturers.

“The Chinese need the Su-35 in order to copy radar and engine technologies, as was the case with the Su-27”

The state-owned Aviation Industry Corporation of China (AVIC) lost the fight to retain its core engine-building business. In the upper echelons of power, it was decided to isolate assets, including factories and design institutes, united under the Avik Engine brand. As for the prospects of a separate division of the corporation, which is trying to create a competitive civil turbofan engine (TVD) - ACAE (AVIC Commercial Aircraft Engines), they have not been determined. Although it is obvious that this asset can also be integrated into the engine building group being created.

Avik management lobbied for the preservation of its engine-building business, formed during the reorganization of the corporation in 2008. At the same time, the American weekly Aviation Week predicted the separation of this segment back in May. It is likely that relevant information will not become available until decisions on appointments are made. Discussions of candidates are already underway, one of the top managers in the aviation industry told the publication. But in the world of Chinese state-owned enterprises, appointment is a long-term question. Rivals use connections to secure positions, and the final decision may be the result of a lengthy political struggle.

Why is this necessary?

The aircraft engines created must be suitable for different airframes and, conversely, airframes must be able to be equipped with different engines. The independence of the developers of both ensures cost savings and maximizes the efficiency of the products created.

However, in China one cannot expect significant results from such a reorganization, experts note, since the engine-building industry in China is so uncompetitive that it needs additional support to implement its projects. At the same time, separating these industry sectors could rid aircraft manufacturers of one of the worst features of the Chinese aircraft industry - the habit of developing new engine for every glider. It is due to the natural desire of manufacturers to have their own projects, aggravated in China by the fact of a general shortage of jobs and embodied through a mechanism that allows top managers of the aviation industry to impose the choice of power plant on airframe designers. As a result, efforts are dispersed and costs increase.

An example is the development by two groups of specialists of different engines in the same thrust class: one creates the WZ-20 turboshaft with 6000 kW (8000 hp), and the other creates the WJ-10 turboprop with 5000 kW. In any other country it would be the same motor - provided that the airframe manufacturer requires a cost-effective solution.

Considered a less promising but more achievable alternative to ACAE's turboprop engines, the WS-20 engine is equivalent to Western powerplants developed decades ago. It is intended to equip the Y-20 strategic transport aircraft of the Avik corporation. Now, due to the separation of engine-building assets from it, the achievement of full combat readiness of this aircraft is being pushed back to a more distant future.

In 2008, Avik management tried to position the WS-20 as a unified engine. The corporation hoped that it would be used as a power plant for passenger plane C919 from Comac (COMAC – Commercial Aircraft Corporation of China). However, they were against using the completely ineffective WS-20 in their developments. Senior officials agreed with this argument and decided to create a division of ACAE, which was tasked with creating a Chinese engine by 2020 that would be competitive with CFM's Leap 1 or Pratt & Whitney's PW1100. (Pratt & Whitney).

However, experts believe that the ambitious goal set is achievable only through the intensive involvement of foreign technologies. At the same time, Western engine manufacturers refused to cooperate. Even if the potential revenues compensated for the transfer of sensitive technologies, Western governments would object.

It follows that ACAE will not make significant progress with the development of its CJ-1000 engine. Moreover, since China intends to create an aircraft engine company based on Avik Engine, the currently independent ACAE is expected to join it too.

Showdowns and prospects

We are talking, in particular, about the WS-20. The developer of this engine, the Shenyang Engine Design and Research Institute (SEDRI) of the Avik company, despite everything, did not abandon the intention to install the WS-20 on the C919. ACAE officials criticize him for low efficiency, to which SEDRI reasonably objects: this engine at least exists in reality.

However, this does not mean that the WS-20 has reached the required level of technical readiness. According to reports, it combines elements of the military WS-10 Taihang turbofan engine (TJE) with a low bypass ratio and the civil CFM56 of earlier versions. The technical level of development is approximately similar to the CFM56-3, which appeared about 35 years ago. In particular, its fan includes blades with narrow chords, similar to the first Western and Soviet turbofan engines with a high bypass ratio.

In all likelihood, the Chinese developers decided at an early stage that they should create a low-pressure cascade similar to the CFM56. In any case, experts note that several CFM56 engines purchased by China are not in service, most likely they were disassembled for analysis and copying. A similar situation has developed with regard to the A320 aircraft - several purchased airliners are not in operation, probably because they are dismantled and serve as reference material to create a C919 of similar dimensions.

Since the Y-20 aircraft, which made its first flight in January 2013, is now equipped with the old Russian D-30KP medium bypass ratio, it is assumed that by the time the WS-20 is fully ready, the characteristics of this transporter will be significantly improved. However, Western analysts note, given technical level WS-20, you should not count on a noticeable increase in performance.

In addition, SEDRI is still far from completing the development of the WS-20. Recently, the Research Institute presented an improved version of the WS-20-15 with outstanding characteristics, including an incredibly high pressure ratio of 45:1. Accordingly, either the modern version or the intermediate one will be based on the CFM56-5C engine, which appeared on the market in 1993 to equip the A340-200 airliner. In any case, the Y-20 transport aircraft requires an engine with a thrust of 15,000 kgf, which corresponds to the characteristics of the CFM56-5C.

The introduction of at least the initial version of the WS-20 will represent a huge step forward for the Chinese aircraft engine industry. At least the PLA Air Force will be able to use this domestic engine at least for standard modes work in which all the shortcomings will appear and ways to solve them will be found.

The SEDRI Institute, hoping to install a civil version of the WS-20 on the C919 aircraft, does not have any cooperation with the Comac company, which relies on the CJ-1000 engine. At the same time, a representative in the leadership of the aviation industry believes that the civilian version of the WS-20 has an advantage, at least in the sense that it can attract foreign partners to cooperate to the extent that Western governments are ready to allow in the field of some subsystems.

The West will help as much as they allow

Regardless of what the West decides to do, the closed nature of Chinese industry itself could become an obstacle to international cooperation. Once, for example, the leadership of the People's Republic of China intended to attract foreign specialists to assist in the integration of one of the internally developed subsystems into an engine. At the same time, however, it did not dare to reveal even the name of the institute in which it was designed this equipment. It was simply impossible to work with the system without being able to discuss its characteristics with the manufacturer.

However, the French group Safran is cooperating with China. She carefully doses contacts to avoid transmission high technology, but at the same time she was so pleased with the first experience of cooperation with Chinese specialists that she hopes for its continuation. We are talking about the production of the Ardiden-3C engine, called WZ-16 in China and used to equip AC352 helicopters - the EC175 version, which is being developed by the Chinese company Avicopter together with Airbus Helicopters ). The presentation of this program in 2010 created a sensation, since cooperation in the field of aircraft engines invariably involves the transfer of know-how applicable to military aviation. However, the hot part of the Ardiden-3C engine was worked on by Safran Group's Turbomeca, while China's Avik Engine was working on less sensitive technologies.

In the second stage of cooperation, the Safran group's aircraft engine developer, Snecma, will take part in an unusual program in which Chinese specialists will train the Western partner on certain issues in the field of aircraft propulsion systems. We are talking about turboprop technologies, in which Snekma has no experience, while China, on the contrary, has been heavily involved in this topic both in the production of former Soviet engines and in the development of its own products WJ-10 and WZ-16 with a power of about 3800 kW .

A number of preliminary agreements have been signed to implement the program. The French government showed great concern about this program, but then gave its consent.

As planned, the parties will first jointly explore the technologies of the power turbine and combustion chamber flame tubes. If it comes to a full-scale engine, a corresponding program for the development and production of the necessary components will appear.

Two years ago, Snekma also proposed to China to jointly develop a large turboshaft engine based on the GG of its Silvercrest engine, intended to equip business jets. It could generate power up to 6000 kW to support the flight of a promising heavy transport helicopter, which is expected to be jointly developed by Avik and the Russian Helicopters holding company. However, Avik Engine began developing the WZ-20 engine instead.

"Russian sector" will grow

The USSR played a special role in the development of Chinese aircraft engine manufacturing and Russia continues to play. Soviet jet engine AL-31F developed by Design Bureau named after. Cradles were purchased by China in various modifications. This, in particular, is the basic production model used to equip the Su-27SK, licensed assembly of which was carried out by Shenyang Aircraft Corporation (SAC) in Liaoning Province. Other versions were sent to Shenyang's main competitor, Chengdu Aerospace Corporation (CAC), which is based in the capital of Sichuan province. The latest version, AL-31FN, was specially developed to equip the single-engine Chinese J-10A fighter.

As reported general manager Russian United Engine Corporation (UEC) Vladislav Masalov, now Ufa Engine Manufacturing production association(UMPO) is fulfilling a contract for the supply of basic AL-31F to China, and the research and production center for gas turbine construction "Salut" is supplying AL-31FN aircraft engines, and is already completing an order for the second series of these power plants and is beginning work on the AL-31FN third series . Application received for additional supply 75 such engines in the period 2015–2016. UEC plans to begin work on the creation of the AL-31FN of the fourth series for the PRC. In addition, the St. Petersburg company Klimov modified the Russian RD-33 engine into the RD-93 version, which is now equipped with the Chinese FC-1/JF-17 fighters and their export versions.

In 2005, Rosoboronexport entered into a main contract with the Chinese side for the supply of 100 RD-93 turbofan engines, which was completed in 2010, and an option for the additional purchase of another 400 engines of this type. This year, a supply agreement was signed until 2016 inclusive of another 100 power plants under a previously issued option.

UEC and the Chinese National Aero-Technology Import and Export Corporation (CATIC) will jointly modernize the RD-93 to increase its power. The parties signed a corresponding agreement at the international aviation and space salon Airshow China 2014. According to some reports, the fifth-generation stealth fighter J-31, which is being developed in China, is equipped with RD-93 engines.

But that's not all. Russia and China are negotiating the supply of up to 24 of the most modern Su-35 fighter jets. If the contract is signed, these aircraft will be equipped with the latest 117C engines, state tests of which were completed in early December. Regarding the possible copying of 117C technologies by China, it is said that the Russian side is quite calm about this prospect.

A representative of the leadership of the domestic aviation industry even expressed the idea that we should help the PRC and supply the Su-35. “China needs this plane,” the official said. – Because without it you will not be able to advance to the next level of technology development and will never solve existing problems design. We understand that the PRC is not interested in equipping several squadrons of the PLA Air Force with Su-35 fighters. Beijing needs this aircraft in order to copy the radar technology and 117C engine developed by Saturn, as was the case with the Su-27. Without the Su-35, the Chinese will continue to remain in their current state and will never overcome their dependence on Russian engines and other systems.”

Meanwhile, the 117 engine was created on the basis of the 117C, which is equipped with the promising aviation complex front-line aviation (PAK FA) or simply a fifth-generation fighter. It can be assumed that the Russian position is explained by the fact that 117 is an engine to equip the PAK FA at the first stage, while it is already being replaced by a new generation power plant - “product 30”.

Russia also expects, in partnership with China, to develop an engine for a joint Russian-Chinese wide-body long-range aircraft. But these plans are not yet obvious. As expected, at the first stage, an engine will be selected to equip this aircraft from among those available on the market. And at the second stage it is necessary to form a cooperation of Russian and Chinese specialists. According to the Perm-based Aviadvigatel OJSC, the latest Russian PD-14 unit, being developed for the promising MS-21 airliner, can be taken as a basis.

Remains open question, who will be the main contractor, since Perm enterprises are overloaded with work for the next three years. There are suggestions that the Samara OJSC Kuznetsov will act as an integrator. In any case, this is the point of view of Deputy Minister of Industry and Trade Yuri Slyusar.

Photos and information on R-79-300

You don't even know what to say :(

It will probably be interesting to compare with the R-79V-300 (AMNTK data in brackets)

Maximum thrust in afterburner – 161.86 kN (154 kN)

- without afterburner 105.22 kN (n/a)

Bypass ratio 0.382 (0.81)

Total pressure rise factor 28.71 (22)

Gas temperature in front of the turbine 1477K (1630K)

Maximum diameter 1.02 m (1.39)

Length 5.05 m (4.78)

Weight 1862 kg (1850)

It is reported that from successful creation WS-15 engine China is virtually closing the gap with the United States, Europe and Russia in the development of modern military jet engines.

* * *

Let them first raise the specifications by at least a hundred degrees - then they will take a step towards closing the gap with the developments of 30 years ago. I would also like to look at the data on the resource... :)

The “pi ka” figure of 29 is somehow not particularly believable - IMHO, it’s too crazy. However, let the engine experts have their say on this matter.

It’s very good that two topics “stuck together” for us one to the other: The R-79 engine designed by Oleg Nikolaevich Favorsky (the last of a series of our Great designers who created THEIR OWN and completely advanced machines, which are still being copied, and is still quite actively working in the RAS and at CIAM - but not at Soyuz, unfortunately: what remained from the OKB were the typical “horns and legs”) and the entire Perm bush, according to a colleague under the nickname RuLavan So there really is no sense in the existence of the liquidated Perm Motors OJSC. It was for this reason that almost our entire industry collapsed - I’m not talking about aviation, it just held on until the last, but its time has come: the “third wave of privatization” has covered it and, it seems, will wash it away - I’m talking about the entire industry of the Union .

The fate of the P79 is very characteristic and indicative here. And one more piquant detail: when best friends from the other side of the Ocean, for the first time they showed the design of the now flying 35th, it was supposed to mount a flat nozzle on it, tucked under the belly, like a crustacean’s tail. SUVT was like that. Then LM worked with (by the will of our management) the dying company of the Great Aircraft Designer Yakovlev, collaborated in the transfer of the Yak-141, which no one needed and also devoid of reason, and the nozzle on the 35th became round and rotating. And just for nothing, they say. However, this did not help the residents of the OKB from the Airport...

It's the same with Perm. Let's get through it!

However, having removed the head...

When I read this news about Perm, I still didn’t understand whether we were talking about a real Perm engine-building cluster or about some rather ephemeral joint-stock company that had fulfilled its function and is now not needed. what it owns, how many and what kind of specialists work there, in the office specifically with this from the legal article. name?

If this is not a “duck” or a “order” (but about Perm in the early 90s and, accordingly, the PS-90A they already launched this: and they had to fight off such an attack “with the whole world.” They fought back, praise the Creator of Ideas), then everything seems to be - about a real plant.

However, at one time about the plant. Chernyshev (Tushinsky), so specifically on behalf of his leadership, a certain unseen bitch sent out a press release of the same obscene and defeatist mood. I had to pull Novikov (general director) directly to say something. And then there was also a difficult situation there. This, God forgive me, is a raider information attack. Someone also did something similar with Stupino.

So our aggressive and unscrupulous people use misinformation very actively. And until we receive confirmation from the Perm residents or factory workers themselves (or circles really close to them), we cannot say anything.

From annual report JSC "Perm Motors" for 2009

"The main activities of the Company:

1. Management of subsidiaries.

2. Departmental security and safety.

3. Provision of services for events civil defense and mobilization training.

4. Renting out your own non-residential real estate.

5. Property rental.

6. Sale and rental (lease) of real estate for industrial and technical purposes.

7. Intermediary services in the purchase and sale of products for industrial and technical purposes."

The subsidiaries of this OJSC are engaged in leasing premises and housing, as well as managing children's camp. It has no production equipment on its balance sheet. Sells real estate and old spare parts remaining on the balance sheet. It leases to the Perm Motor Plant the in-plant roads of the same plant and access points to its territory (sic!). He makes a modest profit on this, holds 18 meetings of the Board of Directors a year and pays them bonuses at the end of the year.

http://www.oaopm.ru/upload/files/multi/Godov-ot-2009.doc

In general, an ugly superstructure over a plant to suck money out of it. So, Dmitry Aleksandrovich, the “bushes” from Aviadvigatel, Perm Motor Plant, Reductor-PM and others production JSC There is no threat in connection with the liquidation of Perm Motors OJSC. Prosperity and profits to them! :-)

Oh! Kind of like at the factory named after them. Frunze had OOO out of his hands. structure for the sale of TsSKB-Progress rocket engines.

Like, they provided services :)

Dmitry Alexandrovich. informal report on

http://www.forsmi.ru/node/35045

I hope we will see it before the next issue of the magazine?

Rardon for the misspellings, I trimmed the finger on my hand with an electric plane :(

Unfortunately, the detailed topics of the discussions are somehow unknown to me: the organizers, “Arguments of the Week,” didn’t bother. So it will be completely impromptu. As usual, however.

If I have something to talk about, I’ll tell you without the magazine. I promise.

An anecdote from the late 19th to early 20th centuries (either from “Fragments,” or from “The Alarm Clock,” or from a reprise by Bim and Bohm):

1: And our entire editorial staff is abstinent!

2: Tell me! Where have you seen non-drinking journalists?

1: Where have you seen journalists telling only the truth?

I keep what I promised.

“Arguments of the Week” seem to have come up with a way to try to resolve the situation with the failure of domestic technical priorities. The bitter fate of the NK-93 and the Samara Aircraft Engine Design Bureau in particular was chosen as the topic. It is noteworthy that the discussion was attended mainly by factory workers, people from LII who directly participated in the tests, a number of well-known technical specialists and no one from the UEC. Once again, I was the only one who came out of CIAM, and only as an extra. Everything happened under Zyuganov’s door, in the conference reception room of the Communist Party of the Russian Federation (they were the only ones in the Duma for whom the topic was “appropriate”). The GA itself was not present, although it was announced. Led Round table(or, as they now more often say, “moderated” by S.V. Sobko, Chairman of the State Duma Committee on Industry).

Everything was done in a very businesslike and scheduled manner, we met the regulations second by second.

I listened. We talked afterwards.

Well, the topic of NK-93 is well known to the authors and readers of this Conference; there is an excellent separate thread on this subject. BUT: I think the organizers of the Table found the right opportunity. They drew the attention of the Accounts Chamber to what was happening. And the people became quite interested in engaging in the activities of modern “captains of industry.” This turned out to be quite interesting prospects. Maybe in this way it will be possible, if not to stop, then at least to slow down this roller skating rink, under which our entire industry has fallen?

The Accounts Chamber can only reveal. and in order for responsibility to occur (necessary to fight that skating rink), the materials of the joint venture must still be worked out by the prosecutor’s office, and the court. let's hope

But, you must admit, this is still a process, and not an imitation of it. In our country, direct connections do not work out any other way: everything “other” is already captured before action begins.

Dmitry Aleksandrovich Boev: But, you see, this is still a process, and not an imitation of it.

* * *

I would like to believe in this, but alas... This is still the same imitation - just a “higher level”. The same Accounts Chamber checked many people. In particular, when checking the ROE, they found extortionate interest rates that Chemezov and Co. extorted from manufacturers (EMNIP, up to 28). And what has changed?

07:08 Andrey Biryukov writes: "... the Accounts Chamber can only reveal. And in order for responsibility to occur (necessary to fight that skating rink), the materials of the joint venture must still be worked out by the prosecutor's office, and the court. Let's hope..."

And in history modern Russia Was there at least one case when a court convicted someone “from the authorities” “for the collapse”?

/We exclude Khodorkovsky for obvious reasons; he was just imprisoned (officially) “for successful work”.../

We have everything in stock; we’ll bring it if we don’t.

Old engine models DK, DKT, DKV, etc.

Installed on old models of Daf trucks and buses. Straight sixes with the exhaust and intake manifolds on the same side of the cylinder head.

You can see other types of old motors, but we won’t go deeper into this, because... We are not in the business of selling rarities. Founder:

- Power: 156 kW or 212 hp.

- Type: diesel, in-line.

- Volume: 11630.

- Cylinders: 6.

- Valves: 12.

- Compression ratio: 16:1

- Piston stroke: 146mm.

- Cylinder diameter: 130mm.

- Cooling: water.

- Power system: Direct injection.

- Years of manufacture: 8.1967 – 12.1976

How some development and continuation appeared DKT 1160, DKV 1160 etc. The characteristics differ: turbocharged, compression ratio 15:1, in-line pump and:

- DKT - power 213 kW or 290 hp, produced from 1.1974 to 1980, some models were used until 12.1986.

- DKV – and 212kW or 280hp. Years of production: 5/1983 – 9/1991. Installed on DAF F2800.

Installed on DAF ATI, including the 95 series - the ancestor of the XF.

Installed on DAF ATI, including the 95 series - the ancestor of the XF.

The most common modifications in demand are WS 295 (G, L, M, ATI) and WS 315 (G, L, M, ATI). There are also WS 222, 225, 242, 259, 268, 270, 282.

Apparently everyone knows that the number means power in kilowatts, and to find out the number of hidden horses you need to multiply the kilowatts by ~1.35.

For example characteristics WS 315.

- Power: 315 kW or 428 hp.

- Type: diesel, in-line.

- Volume: 11600.

- Cylinders: 6.

- Valves: 12.

- Compression ratio: 14.51:1

- Piston stroke: 146mm.

- Cylinder diameter: 130mm.

- Cooling: water.

- Power system: in-line pump.

- Years of manufacture: 9.1994 –

- Installed on daf 95.430.

Trucks began to be equipped starting with DAF ATI and then on CF, XF and LF, until they were replaced by Paccar internal combustion engines.

The difference between them is in the fuel system. The XF uses an in-line injection pump (IPP), and the XE uses direct injection (individual pump sections), although they are similar in many ways.

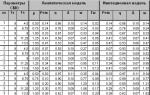

Comparison table.

| Engine XF 315 M | XE 315 C engine | |

| Power | 315 kW (428 HP) | 315 kW (428 HP) |

| Type | Diesel, in-line | Diesel, in-line |

| Volume | 12580 | 12580 |

| Cylinders | 6 | 6 |

| Valves | 24 | 24 |

| Compression ratio | 16: 1 | 16: 1 |

| Piston stroke | 158 | 158 |

| Piston diameter | 130 | 130 |

| Cooling | Vodyanoye | Vodyanoye |

| Power system | In-line injection pump | Direct injection |

| Timing drive type | OHV | OHV |

| Number of main supports | 7 | 7 |

| Camshaft drive | Gear | Gear |

| Years of manufacture | 1.1997 – | 10.1999 – |

Power for XE is 250, 280, 315, 340, 355, 380, 390, 430 kilowatts, for XF 250, 280, 315, 355.

For reference, many have heard that the XF and XE engines also belong to Paccar. As is known from, after the collapse of the British branch of the company, which produced engines for trucks, Daf was bought by Paccar. In fact, later and to this day, Paccar engines are installed on Daf cars.

Characteristics of all fresh engines, as well as the cars on which these engines are installed, are presented in the table.

| FR103 | 103kW / 140hp / 1900-2500 rpm | 550Nm at 1200-1700 rpm | LF45 | 4.5l |

| FR118 | 118kW / 160 hp / 1900-2500 rpm | 600Nm at 1200-1800 rpm | ||

| FR136 | 700 Nm at / 1200-1800 rpm | LF45, LF55 | ||

| FR152 | 152 kW / 207 hp / 2100-2300 rpm | 760 Nm at 1400-1800 rpm | ||

| GR165 | 165kW / 220 hp / 1900-2500 rpm | 850 Nm at 1200-1700 rpm | LF45/55, CF65 | 6.7l |

| GR184 | 184kW / 250 hp / 1900-2500 rpm | 950Nm at 1200-1700 rpm | ||

| GR220 | 220kW / 300 hp / 1900-2500 rpm | 1100Nm at 1200-1900 rpm | LF55, CF65 | |

| PR183 | 183kW / 250hp / 2200 rpm | 1050 Nm at 1100 – 1700 rpm | CF75 | 9.2l |

| PR228 | 228kW / 310hp / 2200 rpm | 1275 Nm at 1100 – 1700 rpm | ||

| PR265 | 265kW / 360hp / 2200 rpm | 1450 Nm at 1100 – 1700 rpm | ||

| MX265 | 265 kW / 360 hp / 1500 – 1900 rpm | 1775 Nm at 1000 – 1400 rpm | CF85 | 12.9l |

| MX300 | 300 kW / 410 hp / 1500 – 1900 rpm | 2000 Nm at 1000 – 1400 rpm | CF85/XF105 | |

| MX340 | 340 kW / 460 hp / 1500 – 1900 rpm | 2300 Nm at 1000 – 1400 rpm | ||

| MX375 | 375 kW / 510 hp / 1500 – 1900 rpm | 2500 Nm at 1000 – 1400 rpm |

What needs to be noted in latest versions engines, these are some improvements that make it possible to increase torque even at low speeds, and over a fairly large frequency range.

In order to increase the reliability of the engine, it was decided to reduce the number of components, because the fewer components, the less likely the unit is to fail. Also, improved oil circulation, low-pressure fuel lines built into the injection pump housing, the use of foam materials to dampen vibrations in electrical wiring, reinforced large bearings and crankshafts, and much more help to increase the durability and reliability of the engine.

Like many other trucks, Daf vehicles are equipped with a retarder in the engine exhaust system, which is activated by the brake pedal. It not only helps to brake effectively, while reducing wear on the service brake system, but also improves braking safety. The point is to increase the resistance to rotation of the crankshaft by preventing the exhaust gases from escaping.

As for the fuel supply system, the less powerful and larger FR and GR models use a high-pressure fuel rail in combination with an injection system. The more powerful and larger PR and MX engines use SMART high-pressure multiport fuel injection technology. In combination with the SCR system, which additionally processes emissions, maximum fuel combustion is achieved with significant fuel savings.

Construction of the new DAF engine.

In-line, 6-cylinder with SCR system, Euro 5.

1. Valve cover.

2. Thermostat housing.

3. Air conditioning compressor.

4. Generator drive.

5. Water pump drive.

6. Drive auxiliary equipment with poly V-belt.

7. Oil sump.

8. Electronic control unit.

9. Air supply pipe.

10. Fuel filter.

11. Fuel pump.

12. Engine cylinder block.

13. Air compressor.

14 High pressure common rail fuel system.

Table about possible installation of engines depending on the cabin.

Don’t forget about the engines of old trucks, because you can still find them, but it’s not always possible to find information and spare parts for them. Fortunately, we can produce such engines in the event of a breakdown, or, if it is impossible to repair, we can replace them at disassembly, and your engine will be counted.

Where are the motors from?

On our (trucks) you can find DAF engines (ICE) of various modifications (with attachments and without), and spare parts for DAF engines (ICE) from the crankshaft, heads or engine block to gears, water pumps, turbines, starters, generators or injectors. DAF engines or engine block are sold only with documents, because... is a numbered unit.

As part of the fifth-generation fighter development program, the aviation industry and related industries need to solve a number of complex problems and create all necessary equipment. One of the most difficult components of such a program is creating an engine with the required characteristics. Projects for advanced power plants are being developed in a number of countries, and several such systems have already been brought to mass production. Let's consider current situation affairs in this area.

Enterprises in the United States were the first to develop engines for fifth-generation fighters. These projects were also the first to be completed, and then brought to mass production and subsequent operation. As a result, the United States has now been able to report new records and a serious lead over foreign competitors. Just a few days ago, American industry announced that it had overcome another important milestone.

Production aircraft F-22A of one of the combat units. US Air Force Photo

The first American engine of the new generation was the Pratt & Whitney F119, created as part of the ATF program and now used on Lockheed Martin F-22 Raptor fighters. A few days ago it was announced that such engines, which have been in full operation for quite a long time, have accumulated a total of 500 thousand flight hours. F119 project manager Amanda Gloade noted that such an achievement clearly demonstrates the capabilities of available technologies. It is also reported that since 2005, all F-22 fighters built have spent a total of 200 thousand hours in the air.

Development of the F119 engine began back in the eighties with the goal of equipping future fifth-generation fighters of the ATF program. The full design contract was signed in 1991. A year later, the first experimental F119 was installed on a test bench, and in 1997 finished goods The new type was tested on prototype aircraft. Pratt & Whitney engines were used on the Lockheed YF-22 and Boeing YF-23 prototypes. The latter did not fully satisfy the military and dropped out of the competition. As a result, the F-22 fighter with the F119-PW-100 modification engine was recommended for serial production.

Production Raptor aircraft are equipped with two F119-PW-100 engines. This product is a turbofan engine with an afterburner and a deflectable nozzle that controls the thrust vector in one plane. The engine is built according to a two-shaft design, the rotors of the high and low pressure circuits rotate in opposite directions. The low pressure compressor has three stages, the high pressure compressor has 6. There is one turbine stage in both circuits. The engine nozzle is flat and has deflectable flaps that allow you to change the direction of the thrust vector.

The Pratt & Whitney F119-PW-100 engine has a total length of just under 5.2 m with a maximum diameter of less than 1.2 m. The product weighs 1.8 tons. The temperature in front of the turbine is 1647°C. Thrust in afterburner - 15876 kgf (according to other sources, 16785 kgf). According to official sources, two F119-PW-100 engines provide the fighter with a thrust-to-weight ratio of at least 0.88. At normal take-off weight this parameter reaches 1.15. It is possible to accelerate to a speed of 2410 km/h. Without the use of afterburner, the aircraft is capable of reaching a speed of 1960 km/h. The combat radius is determined to be 760 km, while the ferry range reaches 2960 km.

A prototype of the F119 engine with a controlled nozzle. Photo: Wikimedia Commons

According to available data, more than 500 Pratt & Whitney F119 engines of all modifications have been produced to date. These products were used on several prototypes of the F-22 fighter, and were later installed on production aircraft. A total of 195 aircraft were built, of which 187 were production and intended for delivery to the air force. According to the latest data, since the official start of operation, Raptor fighters have flown a total of 200 thousand hours. At the same time, the total operating time of the engines, including flight tests of prototypes, reached 500 thousand hours. Thus, becoming the first production engine for a fifth-generation fighter, the F119 product was able to set a record that is unlikely to be broken in the near future.

In addition to the heavy and very expensive F-22 fighter, American industry created the Lockheed Martin F-35 Lightning II aircraft. To equip such equipment, the Pratt & Whitney F135 turbojet engine was created. The development of such a power plant started in the nineties and ended in the middle of the last decade. The F135 engine was created on the basis of the existing F119, which is why the project was initially designated F119-JSF - after the name of the fighter development program.

The development of the F119-JSF / F135 project was completed in the mid-2000s, and the first production model was presented in 2007. Subsequently, the refinement of the technology continued, as a result of which the project was noticeably delayed. However, by 2013, Pratt & Whitney had delivered the 100th production F135 engine. By this time, it was possible to get rid of the bulk of the existing problems, and also to put into production three engine modifications intended for different versions of the F-35 fighter.

Being further development existing product, the F135 engine retains its main features. A dual-circuit circuit with a similar composition of compressor stages is used. The single-stage high-pressure turbine was retained, while a new two-stage turbine was used in the low-pressure circuit. Using various additional devices or technologies, three engine modifications were created: F135-PW-100, F135-PW-400 and F135-PW-600.

A flight of F-35 fighters in flight. US Air Force Photo

The PW-100 version engine is the base product of the family and is intended for installation on the F-35A aircraft of the air force. It has a length of 5.6 m with a diameter of no more than 1.17 m. The mass of the product is 1.7 tons. The maximum thrust of such an engine is 13 thousand kgf, afterburner - 19.5 thousand kgf. Based on the “hundredth” engine, the F135-PW-400 modification was created, intended for the F-35C carrier-based fighters. The only serious difference between this engine is the presence of a reinforced anti-corrosion coating. All characteristics remain at the same level.

The F-35B aircraft, which have short takeoff and vertical landing capabilities, are equipped with F135-PW-600 engines, which have the most significant differences. Such an engine has a rotating nozzle, which allows the thrust to be redirected vertically downwards. In addition, an additional drive shaft is moved forward from the engine, rotating the lift fan. As a result of this redesign, the length of the power plant as a whole increased to 9.37 m, of which 1.35 m is accounted for by the largest parts of the lift fan. The maximum thrust of such an engine is 12250 kgf, afterburner - 18600 kgf.

The first aircraft of the F-35 family were built and flown in 2006. Over the past time, vehicles of three modifications have been brought to full-fledged mass production. More than 230 vehicles have already been built and delivered to the customer. All these aircraft carry one engine of the corresponding modification. The possibility of acceleration to a maximum speed of 1930 km/h is declared. Without the use of afterburner, the F-35A fighter is capable of flying at a speed of 1,470 km/h. The combat radius reaches 1,400 km, the range is at least 2,200 km.

Engine F135-PW-600 with lift fan. Photo: Wikimedia Commons

As we see, the United States, having started work earlier than other countries, has now managed to develop and bring to mass production two turbojet engines for fifth-generation fighters. These products are built in significant quantities and used by the armed forces.

China

China has achieved noticeable success in creating fifth-generation fighters and engines for them. Currently, Chinese industry is working on two promising aircraft at once, and also creating the necessary components for them. At the same time, however, in the field of engine building there is an ambiguous situation. Having limited capabilities in developing modern aircraft engines, the PRC is forced to actively use foreign products.

In January 2011, the fifth generation fighter Chengdu J-20 took off for the first time. To date, several prototypes have been built and tested, differing in configuration and composition of on-board equipment. So, according to known data, experienced J-20s had power plant two versions, both Chinese and foreign production.

Previously, information appeared about the purchase of Russian AL-31F engines, which are distinguished by high performance. Such engines could be used until the start of mass production of aircraft and the appearance of our own products with similar characteristics. Information was also published about the possibility of using the latest modifications of the Shenyang WS-10 engine, which is a Chinese version of the development of the Soviet/Russian AL-31.

Chinese Chengdu J-20 fighter jets during a demonstration flight. Photo: Wikimedia Commons

According to the latest data, production J-20 aircraft will be equipped with Xian WS-15 turbojet engines, which are currently being developed. The project started back in the nineties, and in the mid-2000s it reached bench tests. By the end of the last decade, some positive results were obtained. Earlier, foreign specialized publications suggested that the WS-15 project is a Chinese attempt to copy the American F119 engine. There were also rumors about China's desire to copy Russian engines of the latest modifications of the AL-31 family.

From the available data it follows that the Xian WS-15 product is a turbofan engine with an afterburner. A three-stage low-pressure compressor and a six-stage high-pressure compressor have been reported. The engine has a total length of more than 5 m. At a temperature in front of the turbine of about 1600°C, it is planned to obtain a thrust of up to 19-20 thousand kgf.

According to various estimates, the Chengdu J-20 fighter with two WS-15 engines will be able to show a thrust-to-weight ratio of at least 1.05. At the same time, it will be able to reach speeds of up to 2100 km/h. The possibility of acceleration to supersonic speeds without the use of afterburner has not yet been specified. It is still unknown what characteristics the production aircraft will have with improved engines.

Since 2012, flight tests of the fifth-generation light fighter Shenyang J-31 have been ongoing. According to available data, this aircraft has been tested in a specific configuration for at least some time. It was powered by two Russian-made RD-93 turbojet engines, used on fourth-generation fighters. In the last decade, China was able to launch its own version of the RD-93 called Guizhou WS-13. In the foreseeable future, it is planned to equip J-31 aircraft with an improved WS-13E engine.

Light fighter Shenyang J-31 at an aviation exhibition. Photo: Wikimedia Commons

According to previously published information, the WS-13E will be a two-circuit turbofan engine, which is a further development of the existing RD-93. Serial products of the basic modification WS-13 have eight stages of high and low pressure compressors. With a length of less than 4.2 m and a diameter of about 1 m, the WS-13 engine weighs 1.14 tons. The existing product in afterburner develops a thrust of more than 8800 kgf. IN new modification WS-13 afterburning thrust is planned to be increased and brought to 9-9.1 thousand kgf.

For obvious reasons, the exact status of the promising WS-13E and WS-15 projects is not disclosed. Chinese defense industry traditionally keeps its main secrets and is in no hurry to announce the most interesting information about new projects.

Russia

Russian industry continues to work on its only fifth-generation fighter project - the PAK FA or T-50. As part of a major program, the development of a promising engine is also underway, differing from existing models in improved performance and new capabilities. However, the complexity of such work led to the fact that experimental aircraft had to be equipped with existing types of engines that had acceptable characteristics. T-50 prototypes are currently equipped with AL-41F1 turbojet engines. In the future, it is planned to complete the development and put into series a completely new engine, currently known under the designation “Product 30” or “Type 30”.

In the context of the PAK FA program, “Product 30” is considered as the so-called. second stage engine. So far this project has only a working designation, but in the future a new name with the letters “AL” may appear. It was previously reported that by now it has been developed design documentation and the assembly of experimental engines began. The installation of Products 30 on a prototype aircraft and the first flight using them are planned for the end of this year. More tests will be carried out over the next few years, and state tests are expected to take place in 2020.

One of the experimental PAK FA/T-50. Photo by Alex S / Russianplanes.net

A few days ago, Gazeta.ru published new details of the progress of the Product 30 project, obtained from unnamed sources at the Moscow Design Bureau named after. A.M. Cradles. According to information from the source, the company works in three shifts in order to meet the deadlines and meet deadlines. set schedule. At the same time, there are problems with related companies: the supplier of automatic engine control does not meet its obligations. After completion of the current work, it is planned to install the prototype engine on a flying laboratory and test it in flight. The first such inspection is scheduled for November 6. However, if the subcontractors do not cope with their tasks, the test schedule may be changed.

Also, a source from Gazeta.ru confirmed that the promising engine is noticeably different from existing products, such as the AL-41F1, but receives a new turbine and a fully digital control system. The consequence of this will be improved traction characteristics combined with reduced fuel consumption. All this will allow an aircraft equipped with Products 30 to develop supersonic speeds without the use of afterburner, with corresponding positive consequences for the use of technology as a whole.

According to various sources, the promising engine will develop thrust up to 11,000 kgf without the use of afterburner and up to 18 thousand kgf with its use. Due to this, the T-50 aircraft will have a thrust-to-weight ratio, depending on the take-off weight, of at least 1. Maximum speed estimated at 2500-2600 km/h, maximum without afterburner - up to 2000 km/h. The Type 30 engine will be equipped with a deflectable nozzle that allows you to control the thrust vector. This will give the aircraft a significant increase in maneuverability in all flight modes.

Despite the rapid development of radio-electronic systems and the growing importance of them, engines still remain one of the most important and difficult parts of advanced aircraft to develop. The special requirements for fifth-generation fighters lead to corresponding consequences in the context of engine construction. Designers have to solve particularly complex problems, without which it will not be possible to meet all customer requirements and create an aircraft with the necessary characteristics.

AL-41-F1 engine used on existing T-50 prototypes. Photo: Wikimedia Commons

At the moment, several countries are working on their own versions of fifth-generation fighters, but not all such developments have progressed far enough. Moreover, only one country was able to bring promising aircraft to mass production. Others are still testing or doing development work. However, obviously, over the next few years, the United States will lose its primacy, since several foreign-developed aircraft may go into production at once.

The situation with engines for promising fighters looks similar, but is noticeably different. Thus, the United States already has two production engines, one of which is also available in three modifications, Russia is only preparing to test the first model for a similar purpose, and almost nothing is known about the progress of Chinese projects. At the same time, it is obvious that the development of promising equipment and components for it continues and gradually leads to more and more new results. The end result of all projects should be the start of mass production of new engines for installation on production aircraft intended for the armed forces. Two new generation engines have already solved this problem. The rest just have to do it.

Based on materials from sites:

http://defensenews.com/

http://globalsecurity.org/

http://airwar.ru/

http://defence-update.com/

http://armyrecognition.com/

http://gazeta.ru/

http://janes.com/

http://flightglobal.com/

http://airforceworld.com/